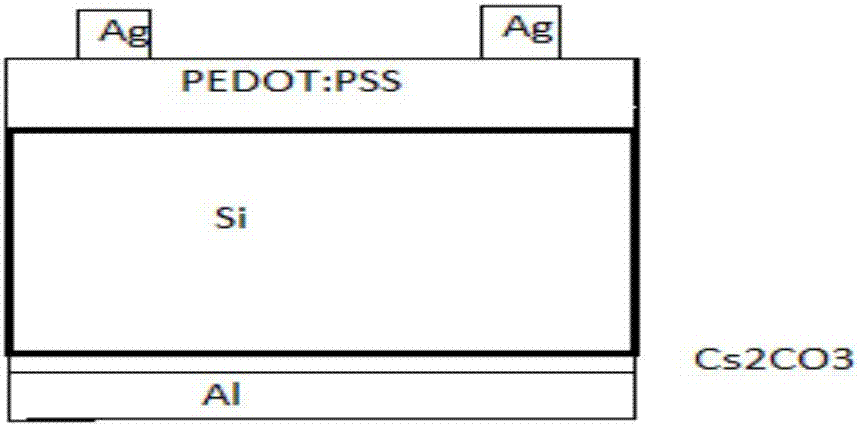

Method for preparing PEDOT:PSS/Si heterojunction solar cell

A solar cell and heterojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of low open circuit voltage and achieve the effect of increasing open circuit voltage and high open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The steps of the preparation method of the present invention are as follows:

[0026] The first step, in German Heraeus company product, model is the poly-3,4-ethylenedioxythiophene of PH1000: polystyrene sulfonate (PEDOT:PSS) solution is mixed with triton (Triton X-100) surface Activator, the mass fraction of Triton X-100 surfactant doped is 0.75%-2%, and the purity is 98%;

[0027] In the second step, apply the PEDOT:PSS solution prepared in the first step on the surface of the silicon wafer, put it into a vacuum vessel and use a mechanical pump to pump air, so that the air pressure in the vacuum chamber reaches 1-100Pa, and maintain the air pressure for 3 minutes to remove Bubbles in PEDOT:PSS solution;

[0028] The third step is to take out the silicon wafer coated with the PEDOT:PSS solution, and spin coat the PEDOT:PSS solution with a coater to form a film, the spin coating time is 60s, and the rotation speed is 6000rpm. After the film is formed, place the silic...

Embodiment 1

[0035] The first step, in German Heraeus company product, model is the poly-3,4-ethylenedioxythiophene of PH1000: polystyrene sulfonate (PEDOT:PSS) solution is mixed with triton (Triton X-100) surface Active agent, the massfraction of the triton (Triton X-100) surfactant of doping is 0.75%, and purity is 98%;

[0036] In the second step, the PEDOT:PSS solution prepared in the first step is coated on the surface of the silicon wafer, put into a vacuum vessel and evacuate with a mechanical pump, so that the air pressure in the vacuum chamber reaches 100Pa, and keep the air pressure for 3min to remove PEDOT: Air bubbles in the PSS solution;

[0037]The third step is to take out the silicon wafer coated with the PEDOT:PSS solution, and spin coat the PEDOT:PSS solution with a coater to form a film, the spin coating time is 60s, and the rotation speed is 6000rpm. After the film is formed, place the silicon wafer on a hot plate for annealing treatment, the annealing time is 30min, a...

Embodiment 2

[0042] The first step, in German Heraeus company product, model is the poly-3,4-ethylenedioxythiophene of PH1000: polystyrene sulfonate (PEDOT:PSS) solution is mixed with triton (Triton X-100) surface Active agent, the massfraction of the Triton X-100 surfactant of doping is 2%, and purity is 98%;

[0043] In the second step, the PEDOT:PSS solution prepared in the first step is coated on the surface of the silicon wafer, put into a vacuum vessel and evacuate with a mechanical pump, so that the air pressure in the vacuum chamber reaches 100Pa, and keep the air pressure for 3min to remove PEDOT: Air bubbles in the PSS solution;

[0044] The third step is to take out the silicon wafer coated with the PEDOT:PSS solution, and spin coat the PEDOT:PSS solution with a coater to form a film, the spin coating time is 60s, and the rotation speed is 6000rpm. After the film is formed, place the silicon wafer on a hot plate for annealing treatment, the annealing time is 30min, and the anne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com