Combustible gas high-pressure cylinder storage protection cabinet and method

A technology of high-pressure gas cylinders and storage cabinets, which is applied in the direction of gas processing/storage, gas/liquid distribution and storage, container filling methods, etc. It can solve problems such as prone to dumping, secondary accidents, and undetectable gas leakage, etc., to achieve The effect of reducing the probability of gas explosion, novel and reasonable design, and easy promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

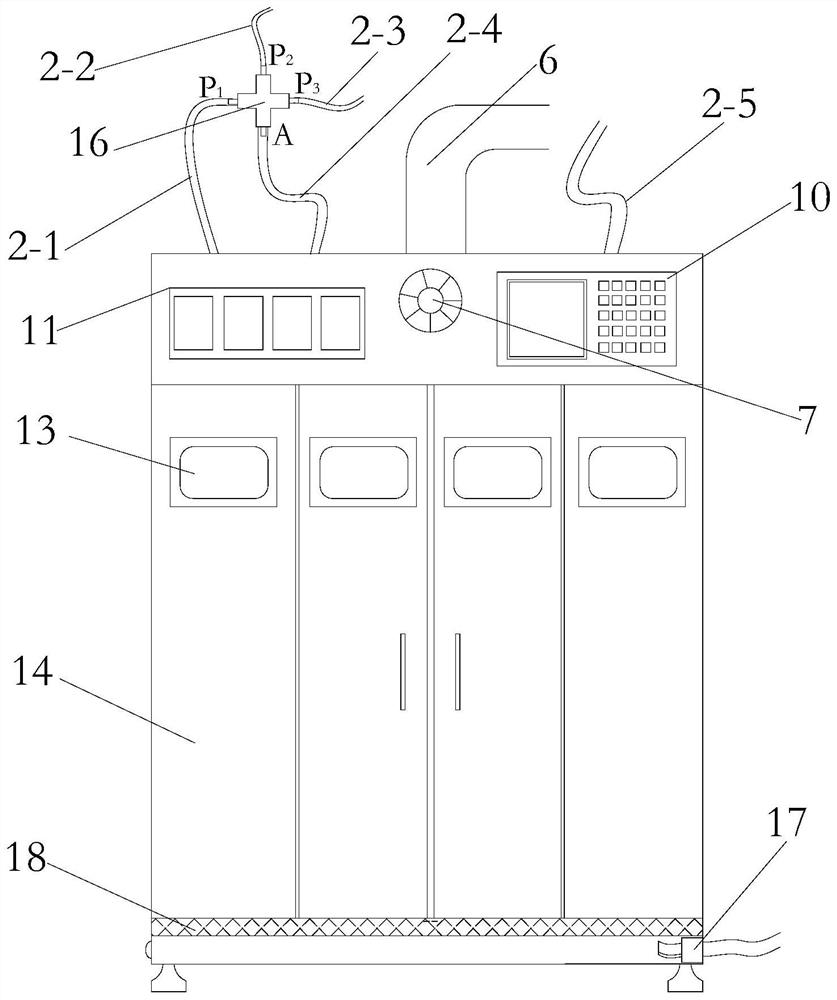

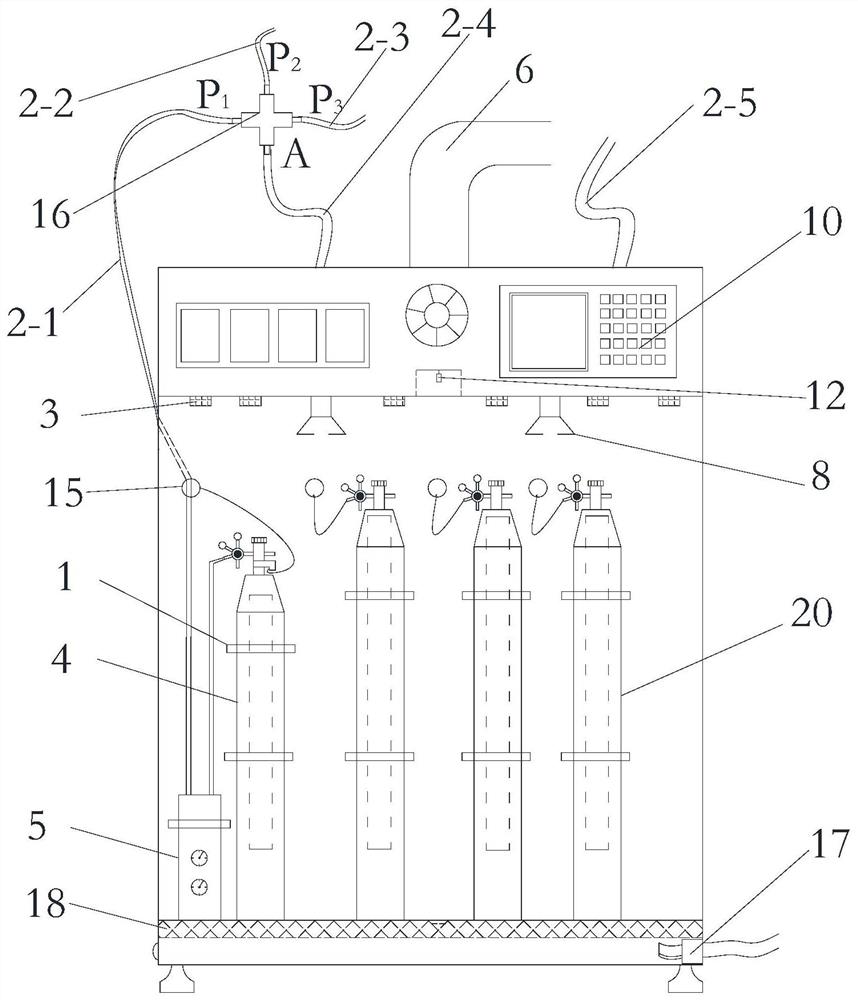

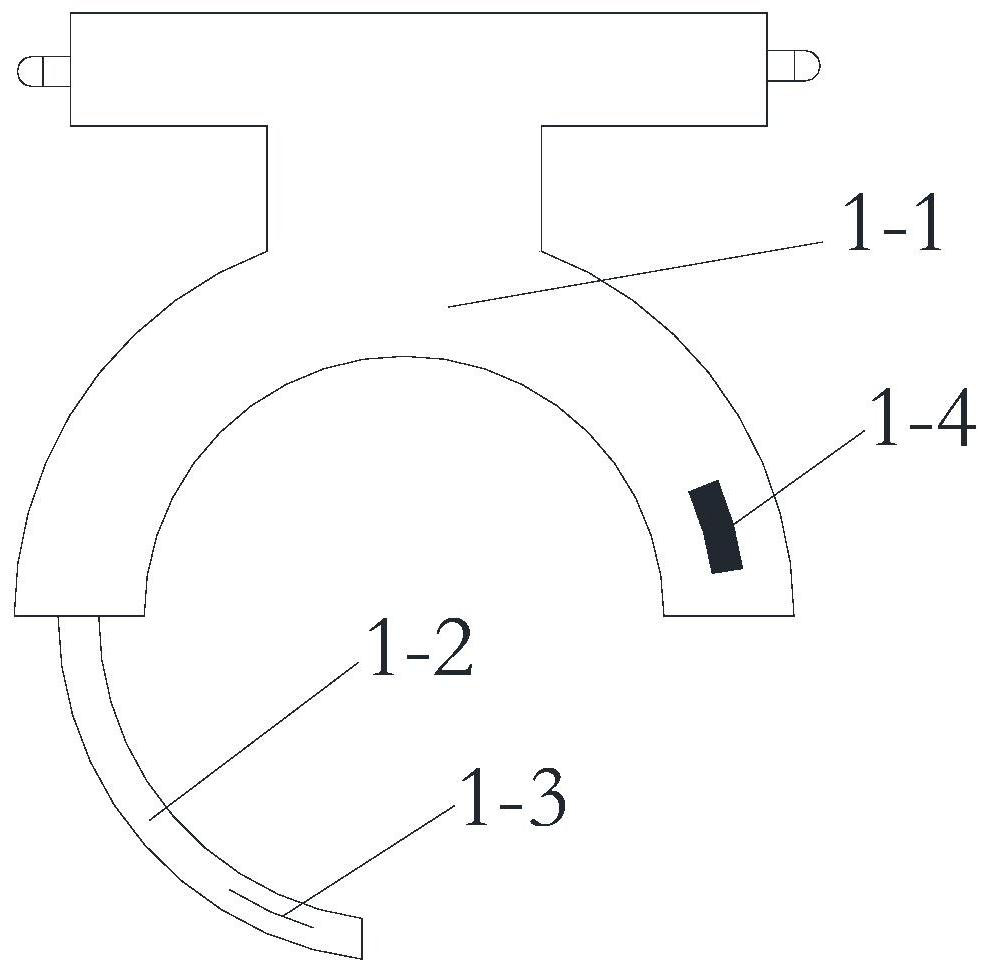

[0048] as Figure 1 and Figure 2 As shown, the flammable gas high-pressure gas cylinder storage protection cabinet of the present invention, comprising a storage cabinet for storing a high-pressure gas cylinder 20 containing a flammable gas and disposed on the upper side of the storage cabinet and processed with the storage cabinet as one of the control cabinets, the lower part of the storage cabinet is provided with steel wire mesh 18, steel wire mesh 18 and the bottom plate of the storage cabinet is provided with a cavity layer connected with the storage cabinet, high pressure gas cylinder 20 is provided on the steel mesh 18, Steel mesh 18 is located on the side of the high-pressure cylinder 20 is provided with a liquid carbon dioxide cylinder 4 and a vaporizer 4 connected to the liquid carbon dioxide cylinder 4, the storage cabinet is provided with a plurality of vertical slides on the inside of the backplane, the vertical slide rail is provided with a sleeve ring 1 for fixing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com