Continuous fiber reinforced ceramic matrix composite material flame stabilizer and its preparation method and application

A flame stabilizer and composite material technology, which is applied in combustion methods, continuous combustion chambers, combustion equipment, etc., can solve the problems of burning engine parts, increasing engine load, and destroying engines, and achieves increasing engine thrust, reducing component weight, and reducing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

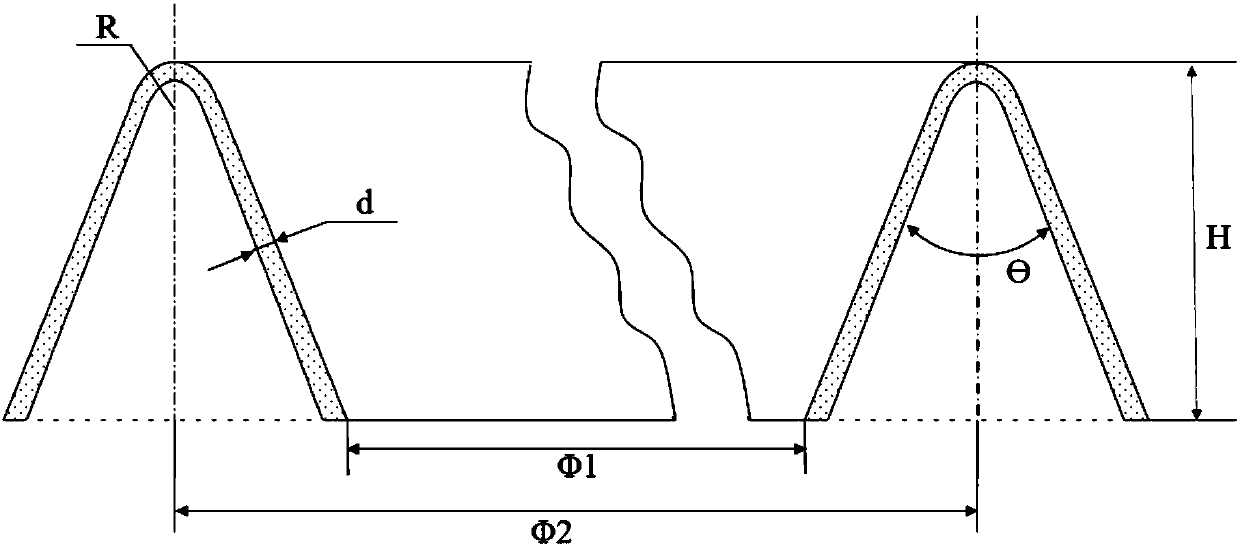

[0022] The invention provides a kind of preparation method of composite material flame stabilizer, comprises the following steps:

[0023] S1: The flame stabilizer prefabricated body is prepared by using continuous SiC fiber in three-dimensional four-way weaving method. In the flame stabilizer prefabricated body, the volume fraction of continuous SiC fiber is 51.2% to 54.6%. The flame stabilizer prefabricated body is shaped according to the design and size processing, the overall size retains a reprocessing allowance of 0.1 to 0.5mm; the surface of the processed flame stabilizer preform is prepared by chemical vapor deposition (C-SiC) n Composite material interface phase, n=1~5, that is, the C interface layer and the SiC interface layer are prepared alternately in sequence, and the C interface layer is in contact with the surface of the flame stabilizer preform; (C-SiC) nThe interfacial phase of the composite material includes a C interface layer and a SiC interface layer: the...

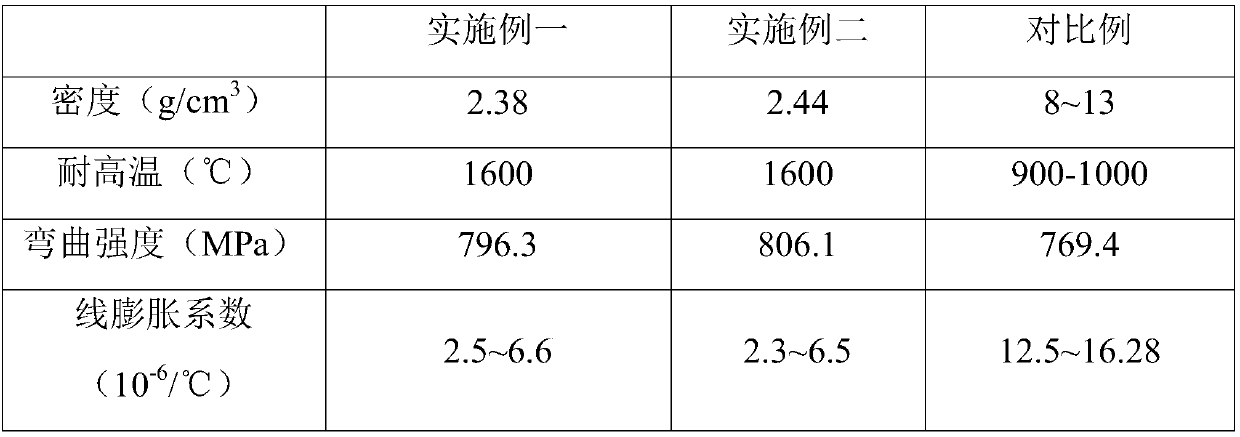

Embodiment 1

[0029] Design the structure and size of the continuous fiber-reinforced ceramic matrix composite flame stabilizer preform according to the working requirements of the engine afterburner; put the continuous SiC fiber into the high-temperature graphite furnace, vacuumize, raise the temperature to 800°C, keep the temperature for 1 hour, and then according to The structure and design dimensions of the flame stabilizer and the prefabricated body of the flame stabilizer were prepared by using the three-dimensional four-way weaving method; the corresponding graphite mold was designed according to the size requirements, and holes were processed on the graphite mold, and the prepared flame stabilizer prefabricated body was put into In the graphite mould, adjust the position and shape of the flame stabilizer preform in the mould, so that the preform is evenly distributed in the mould, close to the actual shape and size, and retain a reprocessing allowance of 0.1mm, combine and fix the mou...

Embodiment 2

[0034] Design the structure and size of the continuous fiber-reinforced ceramic matrix composite flame stabilizer preform according to the working requirements of the engine afterburner; put the continuous SiC fiber into the high-temperature graphite furnace, vacuumize, raise the temperature to 800°C, keep the temperature for 1 hour, and then according to The structure and design dimensions of the flame stabilizer and the prefabricated body of the flame stabilizer were prepared by using the three-dimensional four-way weaving method; the corresponding graphite mold was designed according to the size requirements, and holes were processed on the graphite mold, and the prepared flame stabilizer prefabricated body was put into In the graphite mold, adjust the position and shape of the preform of the flame stabilizer in the mold, so that the preform is distributed in the mold evenly and close to the actual shape and size, and a reprocessing allowance of 0.1mm is reserved, and the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com