A kind of thermal insulation coating for building exterior wall

A technology for thermal insulation coatings and building exterior walls, used in antifouling/underwater coatings, coatings, and biocide-containing paints, etc., can solve problems such as poor stability and low mechanical strength, and achieve good stability The effect of increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

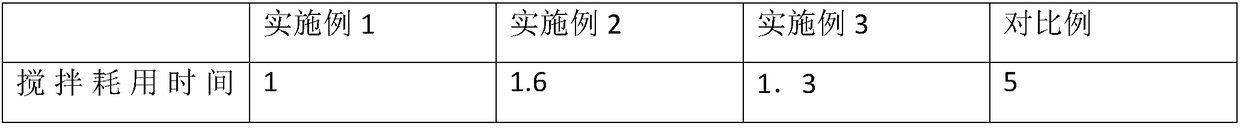

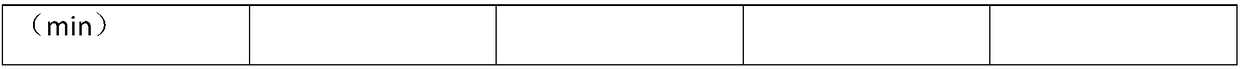

[0025] Get each 500ml of the coating in Examples 1-3 and the coating in the comparative example, paint the outer wall of 1 square meter respectively, and measure the hardness and stability of the coating everywhere after one day. The method of measurement is: A cube with a weight of 500g and a side length of 5mm is placed on the coating, and the depth of the indentation on the coating is measured after ten minutes, thirty minutes, one hour and one day, and the measurement results are shown in Table 3. .

[0026]

[0027] It can be seen from Table 3 that the hardness of the coating of the present invention is higher than that of the coating in the comparative example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com