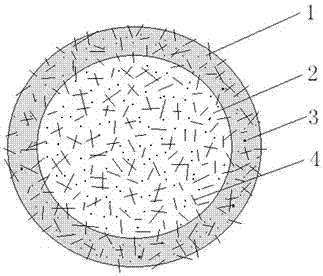

Microcapsule phase-change particles compounding nano-aluminum and carbon nanotube and preparation method thereof

A composite nanoparticle and carbon nanotube technology, applied in the field of materials science, can solve the problems of poor thermal conductivity, poor particle stability, and unfavorable energy storage, and achieve the effects of improving thermal conductivity, low supercooling, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) A step of weighing the core material and the wall material, weighing 40 g of the core material n-octadecane, 10 g of the wall material gelatin and gum arabic according to the core-wall mass ratio of 2:1;

[0044] 2) A step of determining the composite amount of nanoparticles, the total composite amount of composite nano-aluminum and carbon nanotubes accounts for 3% of the total mass of the core wall, i.e. 1.8g;

[0045] 3) A step for preparing a mixture of nano-aluminum and carbon nanotubes, wherein the mass ratio of nano-aluminum and carbon nanotubes is 1:1, taking 0.9g of nano-aluminum and 0.9g of carbon nanotubes to obtain a mixture of nano-aluminum and carbon nanotubes;

[0046] 4) A step of preparing a wall material solution, dissolving the first wall material gelatin and the second wall material gum arabic in 100 g of deionized water respectively to prepare the first wall material solution and the second wall material solution;

[0047] 5) A step of preparing a...

Embodiment 2

[0051] 1) A step of weighing the core material and the wall material, weighing 60 g of the core material paraffin, 10 g of the wall material gelatin and gum arabic according to the core-wall mass ratio of 3:1;

[0052] 2) A step for determining the composite amount of nanoparticles, the total composite amount of composite nano-aluminum and carbon nanotubes accounts for 5% of the total mass of the core wall, i.e. 4g;

[0053] 3) A step of preparing a mixture of nano-aluminum and carbon nanotubes, wherein the mass ratio of nano-aluminum and carbon nanotubes is 1:3, taking 1g of nano-aluminum and 3g of carbon nanotubes to obtain a mixture of nano-aluminum and carbon nanotubes;

[0054] 4) A step of preparing a wall material solution, dissolving the first wall material gelatin and the second wall material gum arabic in 100 g of deionized water respectively to prepare the first wall material solution and the second wall material solution;

[0055] 5) A step of preparing a core mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com