Method for synergistically toughening carbon fiber epoxy compound material by means of porous nanofiber membrane

A nanofiber membrane and composite material technology, applied in the field of nylon 66/carbon nanotube porous nanofiber membrane synergistically toughened carbon fiber epoxy composite materials, can solve problems such as degumming, cracking, and delamination of composite materials, and achieve delamination suppression , improve permeability, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

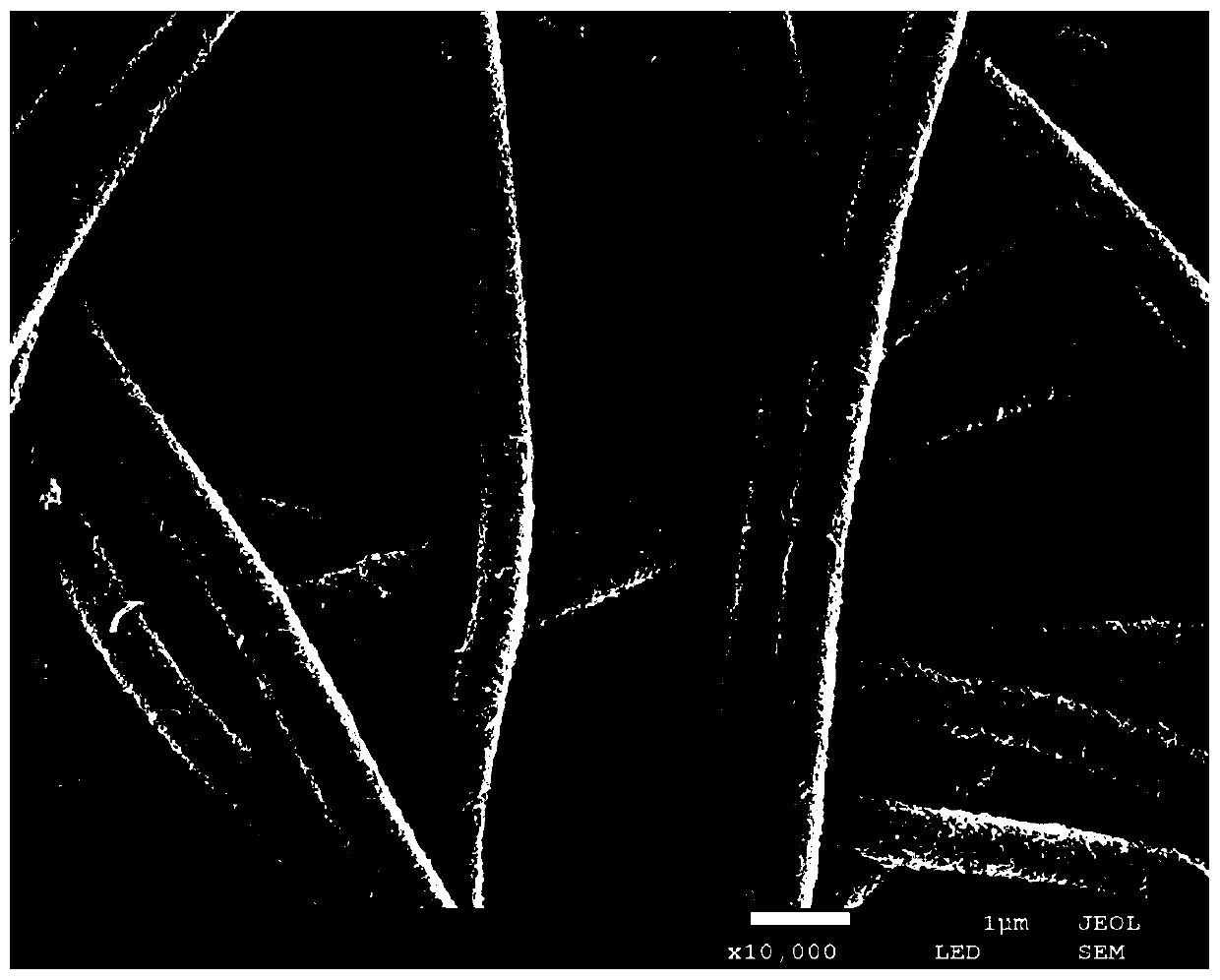

[0034] 1. Preparation of electrospun PA66 nanofiber membrane

[0035] 3 g of PA66 pellets were dissolved in 25 ml of formic acid and methylene chloride at a ratio of 3:2 w / w, and stirred for 4 hours to obtain a PA66 solution with a concentration of 12 wt%. Subsequently, the PA66 solution was placed in a syringe, and PA66 nanofibers with a radius of 100 nm were electrospun onto an aluminum foil collector at a flow rate of 1 ml / h and a voltage of 25 kV. After 15 hours, PA66 nanofiber membranes were collected from the collector.

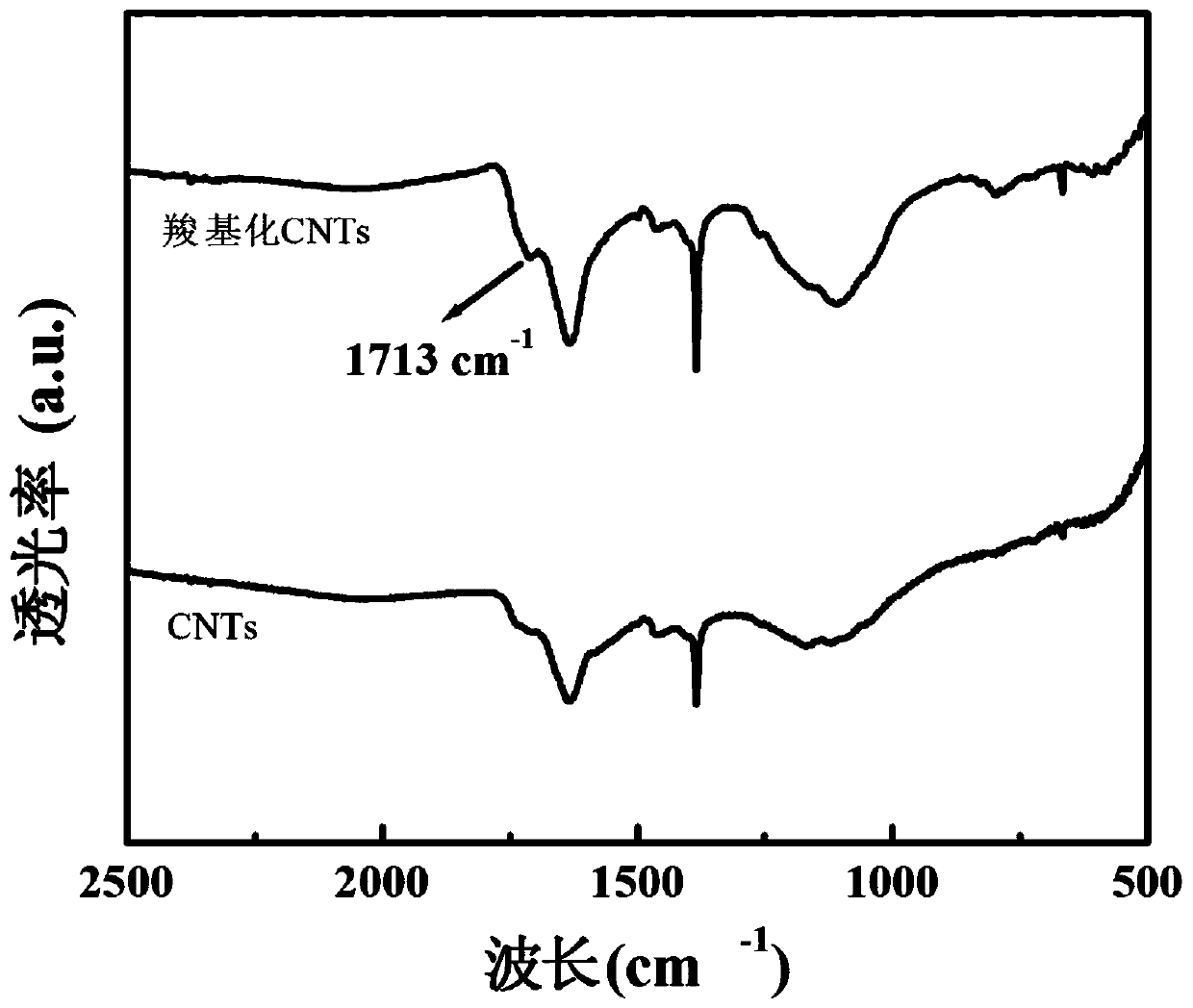

[0036] 2. Preparation of carboxylated CNTs

[0037] Add 3 g of CNTs to 140 ml of H at a volume ratio of 3:1 2 SO 4 and HNO 3 In the mixed acid solution, stir evenly, condense and reflux in a constant temperature water bath at 80°C for 8 hours, add deionized water to dilute to neutral after the resulting mixed solution is cooled to room temperature, and finally put it in a 60°C oven for 24 hours to obtain carboxylated CNTs. The product is characteriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com