Rare earth element-doped bismuth layer-structured multifunctional materials and preparation method thereof

A rare earth element, multi-functional technology, applied in the direction of analysis materials, luminescent materials, material excitation analysis, etc., to achieve stable process, excellent up-conversion luminescence performance and optical temperature sensing performance, and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

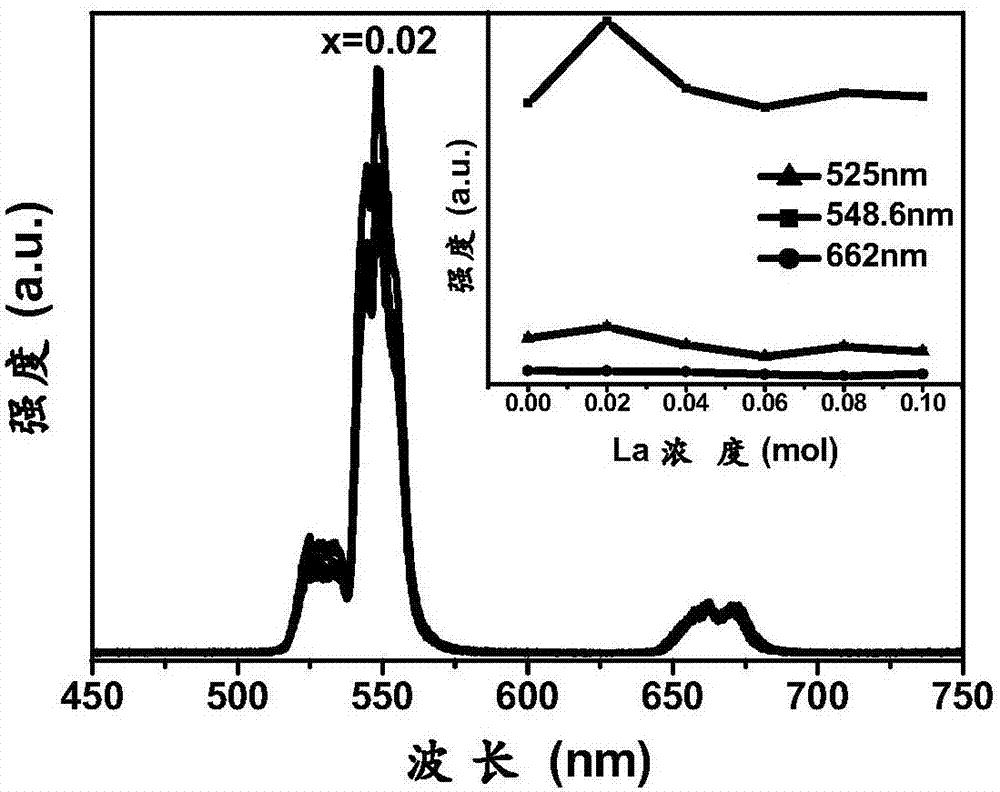

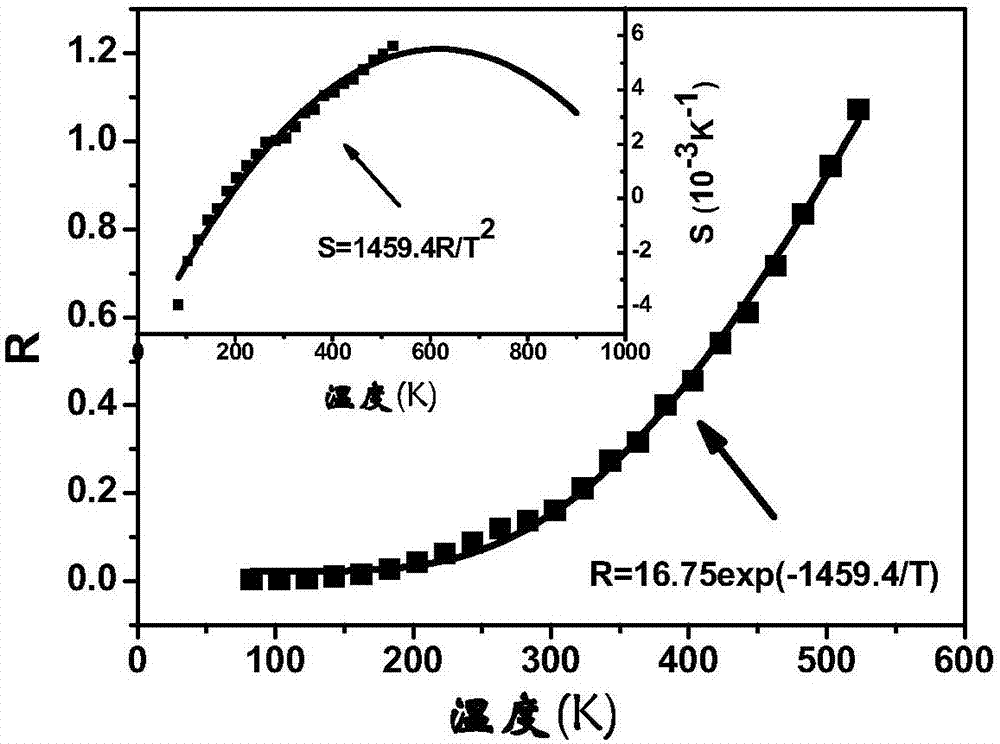

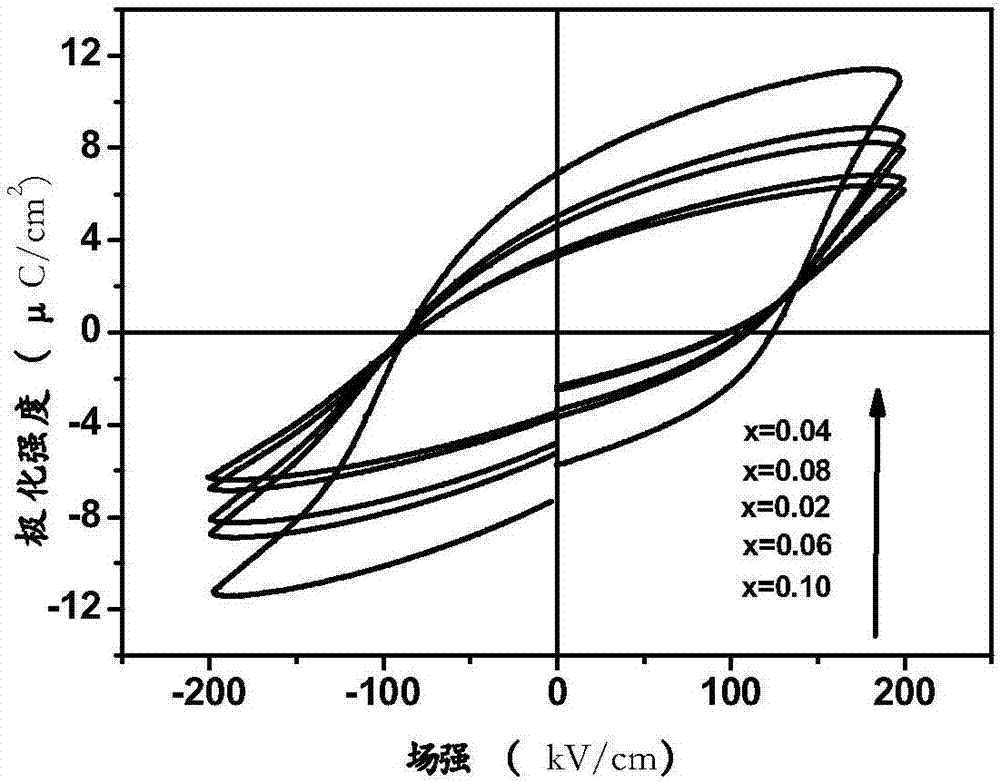

[0028] Preparation of Bi by solid phase method 2.88-x Er 0.03 Yb 0.09 La x Ti 1.5 W 0.5 o 9 Ceramic material, the preparation method is as follows:

[0029] Using high-purity bismuth trioxide (Bi 2 o 3 , 99.5%), titanium dioxide (TiO 2 , 99.99%), Erbium trioxide (Er 2 o 3 , 3N), ytterbium trioxide (Yb 2 o 3 , 3N), tungsten trioxide (WO 3 , 99.8%), lanthanum trioxide (La 2 o 3 , 99.99%) as the raw material, weigh the raw material according to the stoichiometric ratio, put it into an agate mortar, mix it evenly with alcohol as a solvent, and grind it for 3 hours, and put the powder obtained after drying the alcohol into a muffle furnace in the air Pre-fired, the pre-fired temperature is 750°C, the heating rate is 3°C / min, keep the temperature for 4 hours, and then cool down with the furnace to obtain the pre-fired powder. Put the calcined powder into an agate mortar and add an appropriate amount of absolute ethanol and grind it for 2 hours to dry powder. Add an ...

Embodiment 2

[0031] Preparation of Bi by solid phase method 2.97-y Er 0.03 Yb y Ti 1.5 W 0.5 o 9 Ceramic material, the preparation method is as follows:

[0032] Using high-purity bismuth trioxide (Bi 2 o 3 , 99.5%), titanium dioxide (TiO 2 99.99%), Erbium trioxide (Er 2 o 3 , 3N), ytterbium trioxide (Yb 2 o 3 , 3N), tungsten trioxide (WO 3 , 99.8%) as the raw material, weigh the raw material according to the stoichiometric ratio, put it into an agate mortar, mix it evenly with alcohol as a solvent, and grind it for 3.5 hours, and put the powder obtained after drying the alcohol into a muffle furnace in the air Pre-fired, the pre-fired temperature is 750°C, the heating rate is 3°C / min, keep the temperature for 4 hours, and then cool down with the furnace to obtain the pre-fired powder. Put the calcined powder into an agate mortar and add an appropriate amount of absolute ethanol and grind it for 2 hours to dry powder. Add an appropriate amount of polyvinyl alcohol (PVA) with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com