Ultraclean fuel and preparation method thereof

A clean fuel, methanol fuel technology, applied in fuel, liquid carbon-containing fuel, petroleum industry and other directions, can solve the problems of pollution, high cost, limited fuel source, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

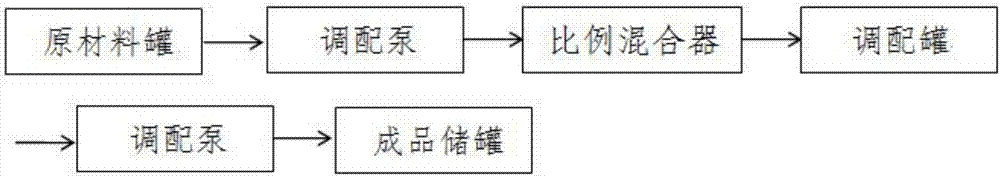

[0033] The preparation method of ultra-clean fuel of the present invention, specifically carries out according to the following steps:

[0034] Step 1, preparing methanol fuel modifier: 10 parts by mass of methylcyclopentadiene manganese tricarbonyl, 5 parts of polymerized calcium sulfonate, 5 parts of sulfurized alkylphenate calcium, borated polyisobutenyl succinyl 5 parts of imines, 20 parts of 2.6-di-tert-butyl-4-methylphenol, 20 parts of methanol fuel corrosion inhibitors, each raw material is weighed, and the raw materials weighed are stirred and mixed to obtain a methanol fuel modifier. Put it into the raw material tank and set aside;

[0035] Step 2, weigh 60 parts of methanol, 10 parts of stable light hydrocarbon, 15 parts of paraffin, 6 parts of dimethylmethanol, 3 parts of 2-methyl-1 propanol, and 8 parts of methanol fuel modifier in parts by mass. Raw material, put into the raw material tank, stand-by;

[0036] Step 3, add the methanol fuel modifier weighed in ste...

Embodiment 2

[0040] The preparation method of ultra-clean fuel of the present invention, specifically carries out according to the following steps:

[0041] Step 1, preparing methanol fuel modifier: 20 parts by mass of methylcyclopentadiene manganese tricarbonyl, 1 part of polymerized calcium sulfonate, 1 part of sulfurized alkylphenate calcium, borated polyisobutenyl succinyl 1 part of imine, 40 parts of 2.6-di-tert-butyl-4-methylphenol, 40 parts of methanol fuel corrosion inhibitor, each raw material is weighed, and the raw materials weighed are stirred and mixed to obtain a methanol fuel modifier. Put it into the raw material tank and set aside;

[0042] Step 2, weigh 15 parts by mass of methanol, 30 parts of stable light hydrocarbons, 40 parts of paraffins, 3-6 parts of dimethylmethanol, 1 part of 2-methyl-1 propanol, and 5 parts of methanol fuel modifier Get each raw material, put into the raw material tank, stand-by;

[0043]Step 3, add the methanol fuel modifier weighed in step 2 ...

Embodiment 3

[0047] The preparation method of ultra-clean fuel of the present invention, specifically carries out according to the following steps:

[0048] Step 1, preparing methanol fuel modifier: 15 parts by mass of methylcyclopentadiene manganese tricarbonyl, 3 parts of polymerized calcium sulfonate, 3 parts of sulfurized alkylphenate calcium, borated polyisobutenyl succinyl 3 parts of imines, 30 parts of 2.6-di-tert-butyl-4-methylphenol, 30 parts of methanol fuel corrosion inhibitors, each raw material is weighed, and the raw materials weighed are stirred and mixed to obtain a methanol fuel modifier. Put it into the raw material tank and set aside;

[0049] Step 2, weigh 40 parts of methanol, 20 parts of stable light hydrocarbon, 30 parts of paraffin, 5 parts of dimethylmethanol, 2 parts of 2-methyl-1 propanol and 7 parts of methanol fuel modifier in parts by mass. Raw material, put into the raw material tank, stand-by;

[0050] Step 3, add the methanol fuel modifier weighed in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com