Composite diesel energy-saving detergent and preparation method thereof

A compound and detergent technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of unsatisfactory carbon deposition cleaning effect in the combustion chamber, single performance of ordinary diesel additives, and unsatisfactory performance such as reducing energy consumption. , to achieve good cleaning effect, improve oil oxidation stability and good diesel solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of above-mentioned compound type diesel oil energy-saving cleaner comprises the following steps:

[0054] First, in the reactor, the organic acid is saponified into a transparent homogeneous liquid by aqueous sodium hydroxide solution; the mass fraction of the aqueous sodium hydroxide solution is 20-40%, and the mass ratio of the organic acid to the aqueous sodium hydroxide solution is (6-8): 1;

[0055] Then react with rare earth brine solution at 60-90°C for 30-60min, separate the liquid and take the upper layer for refining to obtain organic acid rare earth; the mass fraction of rare earth brine solution is 30-50%, and the mass ratio of organic acid to rare earth brine solution is ( 6-8): (9-10);

[0056] Finally, take 1-3 parts of organic acid rare earth, add 30-60 parts by mass of dispersant, 30-60 parts of nitrate, 2-4 parts of antioxidant, and 3-10 parts of Mannich base to mix evenly, and the obtained product is a compound Type diesel ene...

Embodiment 1

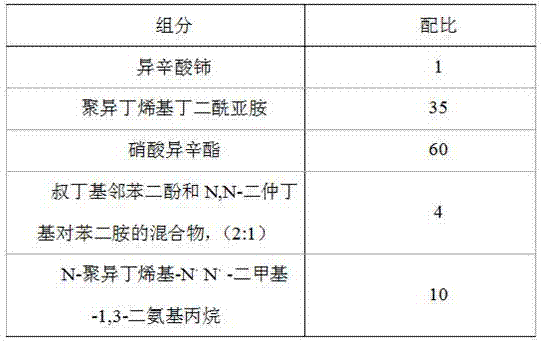

[0065] The embodiment of the present invention provides a compound type diesel energy-saving detergent, and the specific mass ratio of each component is as follows:

[0066]

[0067] In the reactor, the organic acid is saponified into a transparent homogeneous liquid by aqueous sodium hydroxide solution, and then reacted with a rare earth saline solution at 60°C for 60 minutes, and the liquid is separated to take the upper layer for refining, that is, the organic acid rare earth is prepared, and the purified upper layer product Add the substances mentioned in the above table to compound evenly, and the product obtained is the compound high-efficiency diesel energy-saving detergent.

Embodiment 2

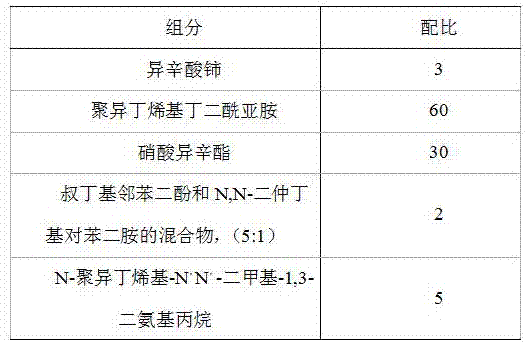

[0069] The embodiment of the present invention provides a compound type diesel energy-saving detergent, and the specific mass ratio of each component is as follows:

[0070]

[0071] In the reactor, the organic acid is saponified into a transparent homogeneous liquid by aqueous sodium hydroxide solution, and then reacted with a rare earth saline solution at 90°C for 30 minutes, the liquid is separated and the upper layer is refined, that is, the rare earth organic acid is prepared, and the purified upper layer product Add the materials in the above table to compound evenly, and the resulting product is the composite high-efficiency diesel energy-saving detergent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com