Low-temperature fermenting apparatus for baijiu

A low-temperature fermentation and equipment technology, applied in the field of liquor low-temperature fermentation equipment, can solve the problems of large labor cost and influence on fermentation quality, and achieve the effect of uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

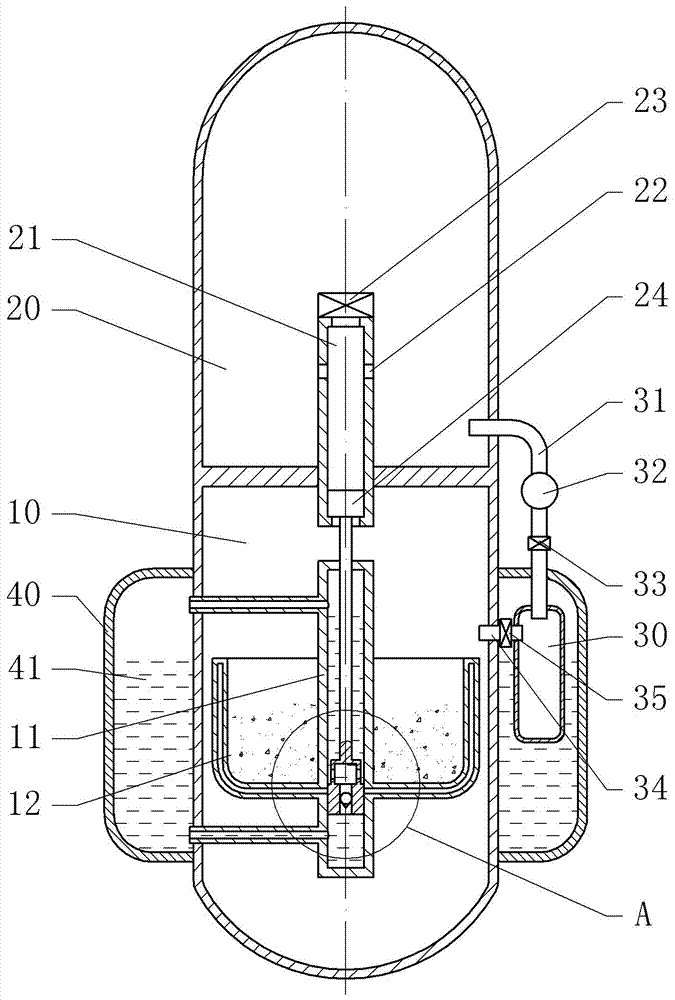

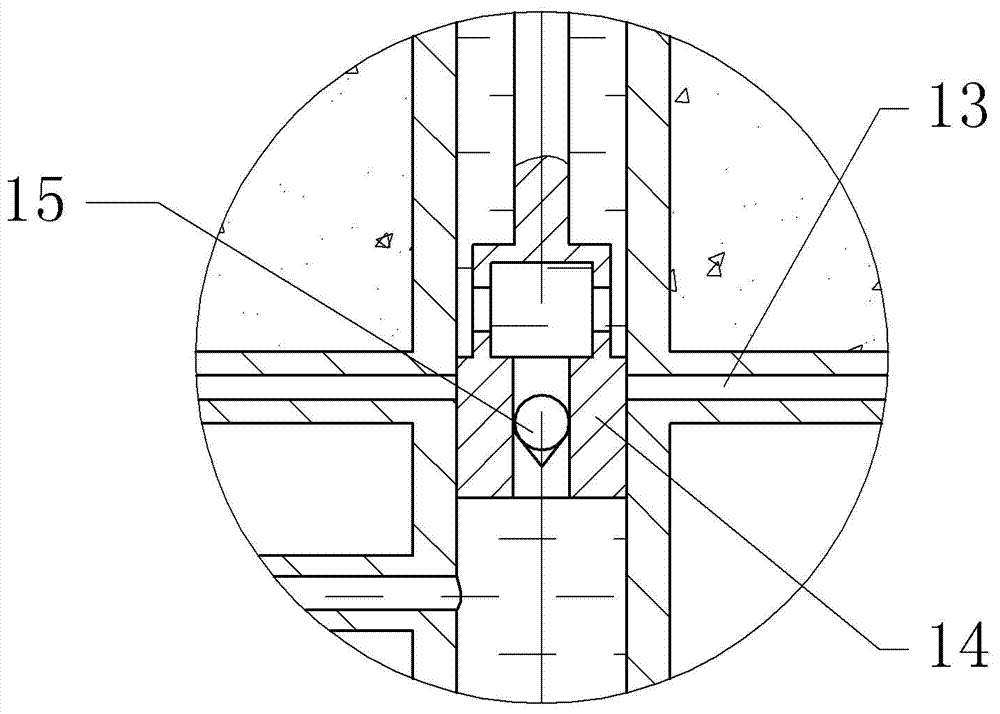

[0024] The present invention will be described in further detail below by means of specific embodiments:

[0025] The reference signs in the accompanying drawings of the description include: fermentation cylinder 10, cooling pipe 11, trough 12, interlayer cavity 13, second piston 14, second one-way valve 15, carbon dioxide storage tank 20, exhaust pipe 21, Exhaust hole 22, magnet 23, first piston 24, carbon dioxide pressure tank 30, communication pipe 31, compression pump 32, first one-way valve 33, air intake pipe 34, solenoid valve 35, water storage tank 40, water storage chamber 41 .

[0026] The embodiment is basically as figure 1 , figure 2 Shown:

[0027] The liquor low-temperature fermentation equipment of this embodiment includes a support, a fermentation cylinder 10 fixed on the support, a carbon dioxide storage tank 20 and a carbon dioxide pressure tank 30, as well as an exhaust pipe 21, a connecting pipe 31, an air intake pipe 34 and a compression pump 32; A fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com