Method for preparing molybdenum disulfide nanoparticles with product form controllable

A technology for nanoparticles and molybdenum disulfide, which is applied in the field of preparing molybdenum disulfide nanoparticles, can solve the problems of single product form, inability to prepare nanoparticles, difficult product form control, etc., and achieves simple and feasible methods, rich product forms, Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

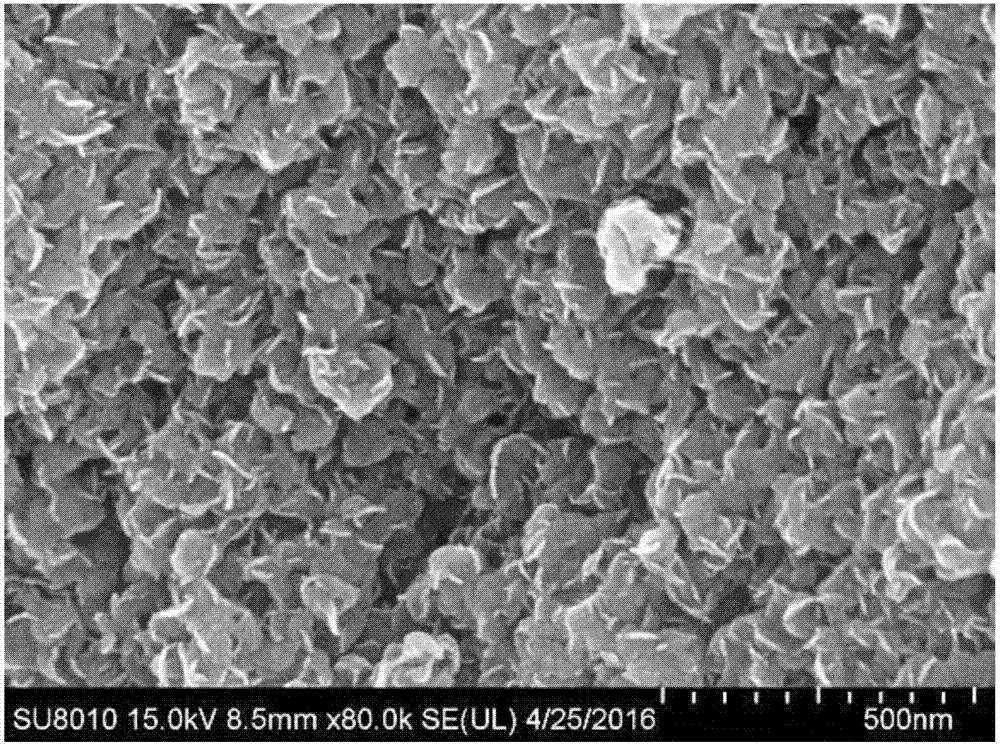

[0021] Dissolve 1.0g sodium molybdate and 2.6g sodium sulfide in 50mL water at the same time, add 0.79g acetamide as a form regulator, add hydrochloric acid under stirring until the pH value is less than 2, sodium molybdate and sodium sulfide immediately dissolve in strong acid The rapid reaction in the solution produces amorphous molybdenum sulfide precipitates, and then MoS is obtained after filtration, washing, drying and calcination in a nitrogen atmosphere at 480 °C. 2 nanoparticles. figure 1 is the MoS prepared in Example 1 2 Scanning electron microscope SEM image of nanoparticles, through figure 1 It can be seen that when acetamide is selected as the morphology regulator, the prepared product is in the form of a partially curled sheet with a size of 100 to 200 nm (compared with the size of about 30 nm prepared when the morphology regulator is not used in the patent CN200710019871.8). nanoflakes are much larger). Because the sheet structure is thin, and other two-dime...

Embodiment 2

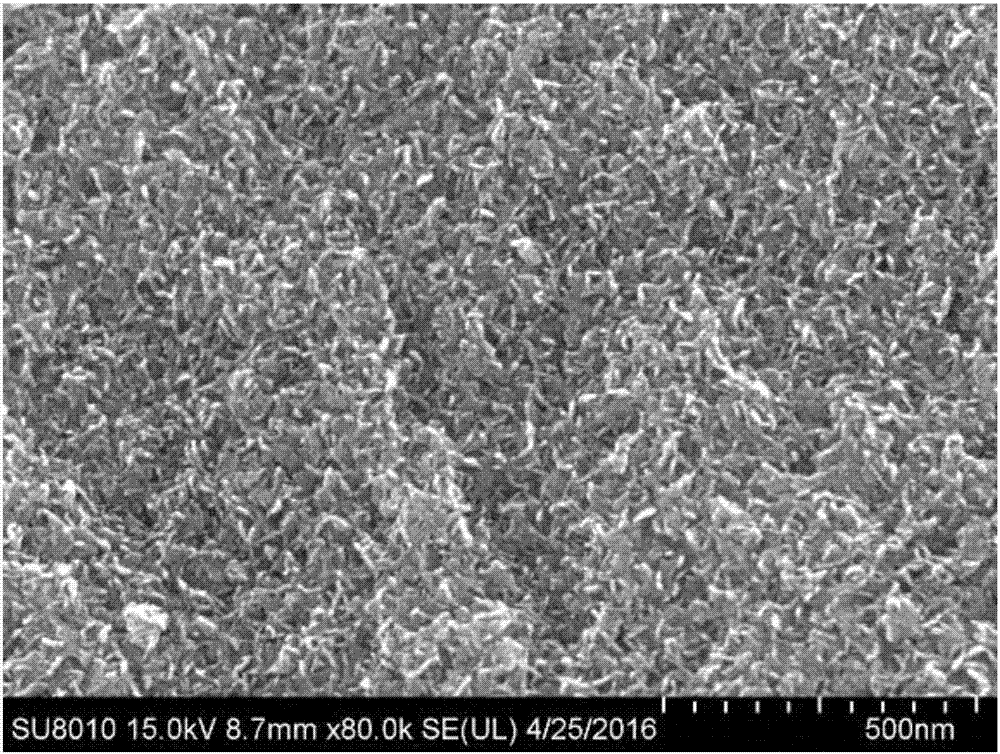

[0023] Dissolve 1.0g sodium molybdate and 2.6g sodium sulfide in 100mL water at the same time, then add 1.0260g ammonium acetate as a form regulator, add hydrochloric acid under stirring until the pH value is less than 2, sodium molybdate and sodium sulfide immediately dissolve in strong acid The rapid reaction in the solution produces amorphous molybdenum sulfide precipitates, and then MoS is obtained after filtration, washing, drying and calcination in a nitrogen atmosphere at 480 °C. 2 nanoparticles. figure 2 is the MoS prepared in Example 2 2 Scanning electron microscope SEM image of nanoparticles, through figure 2 It can be seen that when ammonium acetate is selected as the morphology regulator, the prepared product is in the form of short fibers with a length of 30-100 nm. The short fiber shape is a nanostructure form that is difficult to prepare by existing preparation methods.

Embodiment 3

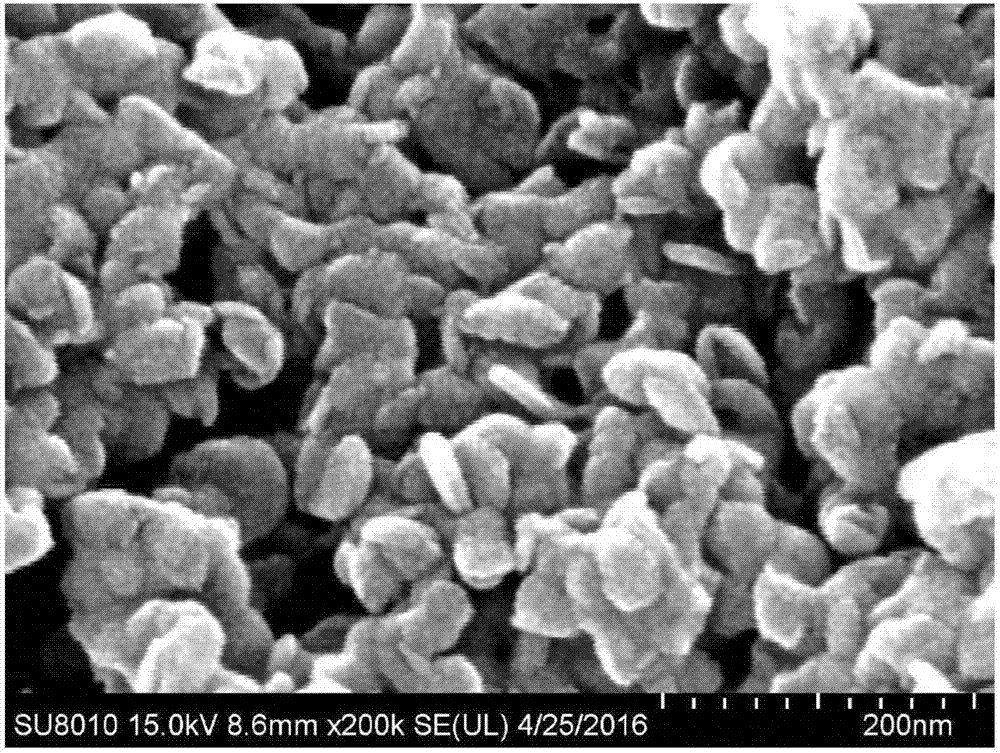

[0025] Dissolve 2.0g sodium molybdate and 2.0g sodium sulfide in 10mL water at the same time, then add 0.5g acetamide and 0.5g ammonium acetate as a form regulator, add hydrochloric acid under stirring until the pH value is less than 2, sodium molybdate and sulfide Sodium immediately reacts quickly in a strong acidic solution to produce amorphous molybdenum sulfide precipitates, and then MoS is obtained after filtration, washing, drying and calcination in a nitrogen atmosphere at 480 °C 2 nanoparticles. image 3 is the MoS prepared in Example 3 2 Scanning electron microscope SEM image of nanoparticles, through image 3 It can be seen that when the shape modifier is acetamide and ammonium acetate at a weight ratio of 1:1, the prepared product is in the shape of a round cake with a diameter of 50-80 nm. This disc shape is a nanostructure shape that is difficult to prepare by existing preparation methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com