High voltage lithium cobalt oxide and preparation method thereof

A lithium cobalt oxide, high voltage technology, applied in chemical instruments and methods, circuits, electrical components, etc., to achieve the effects of high compaction density, stable product performance, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

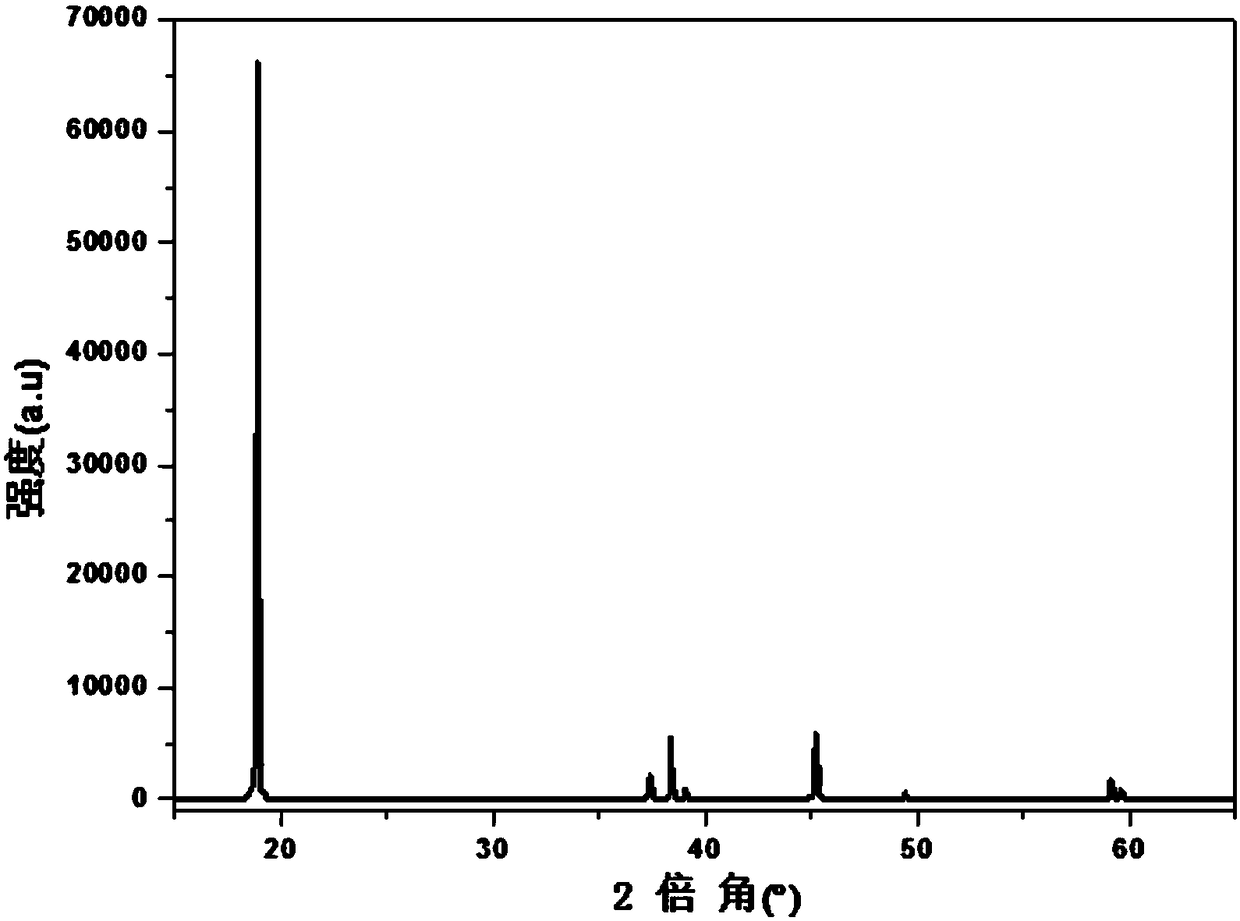

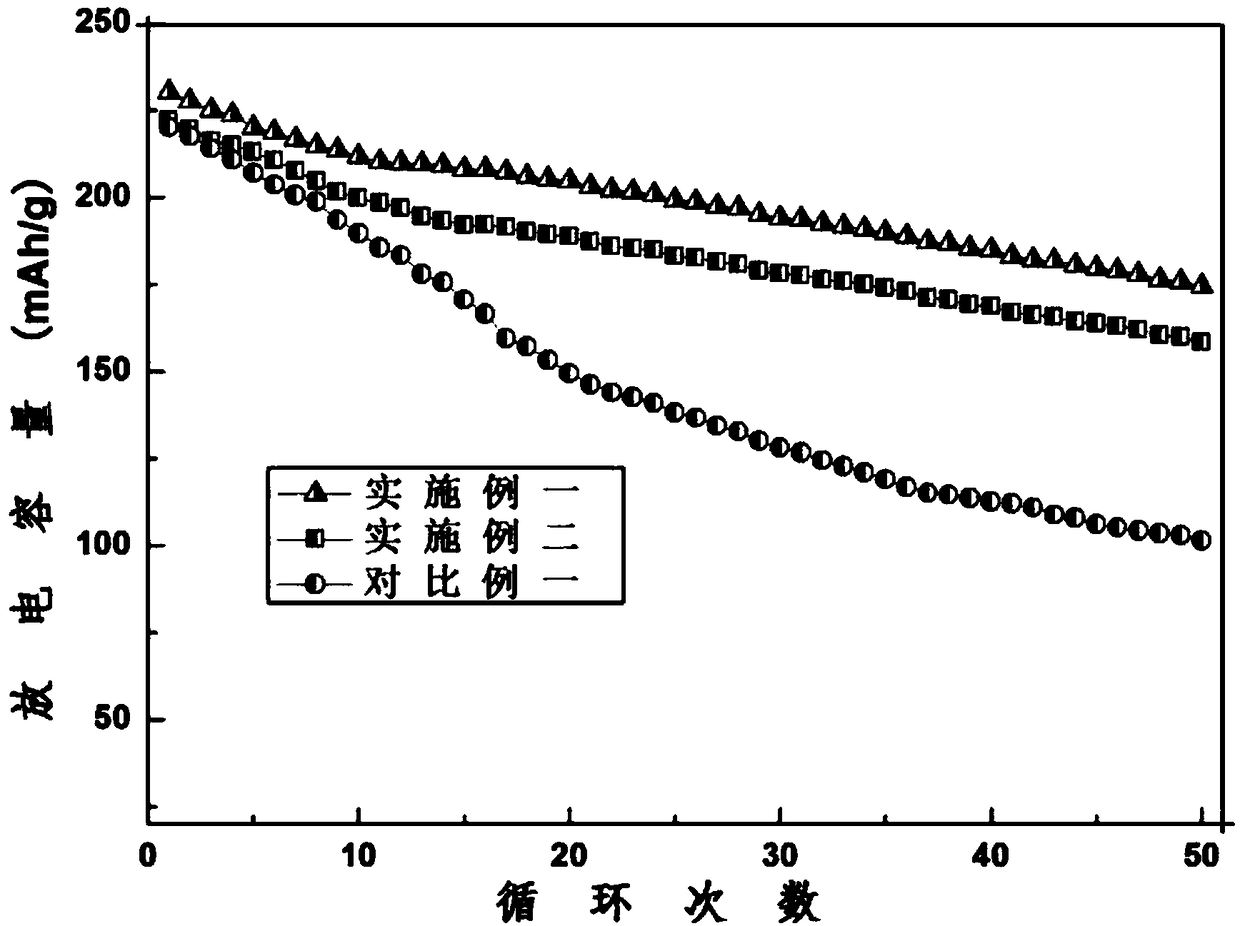

[0026] The preparation method of the high-voltage lithium cobalt oxide provided in this embodiment 1 comprises the following steps:

[0027] Step 1. Select cobalt oxide containing doping elements with a median particle size of 15 μm, wherein the doping amount of the Al element is 3500 ppm, the doping amount of the Mg element is 1000 ppm, and the doping amount of the Ir element is 200 ppm; The molar ratio of cobalt is 1.05, and the amount of doping element is 2000ppm (the doping element is Mn). Weigh cobalt oxide, lithium carbonate and manganese dioxide, mix them by ball milling for 3 hours, place them in a roasting furnace, and place them in an air atmosphere. Roast at 1050°C for 10 hours; crush and sieve the roasted product to obtain a median particle size D 50 18μm lithium cobalt oxide material;

[0028] Step 2. Select cobalt oxide containing doping elements with a median particle size of 2 μm, wherein the doping amount of the Al element is 3500 ppm, the doping amount of th...

Embodiment 2

[0034] The preparation method of the high-voltage lithium cobalt oxide provided in this embodiment 2 comprises the following steps:

[0035]Step 1. Select cobalt oxide containing doping elements with a median particle size of 20 μm, wherein the doping amount of Al element is 2500 ppm, the doping amount of Mg element is 2000 ppm, and the doping amount of Ir element is 500 ppm; The molar ratio of cobalt is 1.05, and the amount of doping elements is 2000ppm. Weigh cobalt oxide, lithium carbonate and manganese dioxide, mix them by ball milling for 3 hours, place them in a roasting furnace, and roast them at 1050°C for 10 hours in an air atmosphere; After the product is pulverized and sieved, the median particle size D 50 22μm lithium cobalt oxide material;

[0036] Step 2. Select cobalt oxide containing doping elements with a median particle size of 8 μm, wherein the doping amount of the Al element is 3500 ppm, the doping amount of the Mg element is 1000 ppm, and the doping amoun...

Embodiment 3

[0042] The preparation method of the high-voltage type lithium cobalt oxide provided in the third embodiment comprises the following steps:

[0043] Step 1. Select the cobalt oxide with a median particle size of 20 μm doping, wherein the doping amount of the Al element is 2500 ppm, the doping amount of the Mg element is 2000 ppm, and the doping amount of the Ir element is 500 ppm; by the mole of lithium cobalt The ratio is 1.008. Weigh cobalt oxide and lithium carbonate, add 2000ppm alumina and 1000ppm trichromium tetroxide, mix them by ball milling for 5 hours, place them in a roasting furnace, and roast them at 1050°C for 18 hours in an air atmosphere; pulverize the roasted products After sieving, the median particle size D 50 22μm lithium cobalt oxide material;

[0044] Step 2. Select cobalt oxide containing doping elements with a median particle size of 8 μm, wherein the doping amount of the Al element is 2500 ppm, the doping amount of the Mg element is 1000 ppm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com