Preparation method of boron nitride fiber enhanced nitride ceramic-based composite material

A technology of nitride ceramics and boron nitride fibers, applied in the direction of radiation unit cover, etc., can solve the problems that limit the wide application, preparation and performance of boron nitride fiber reinforced ceramic matrix composites. The effect of low technical level requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

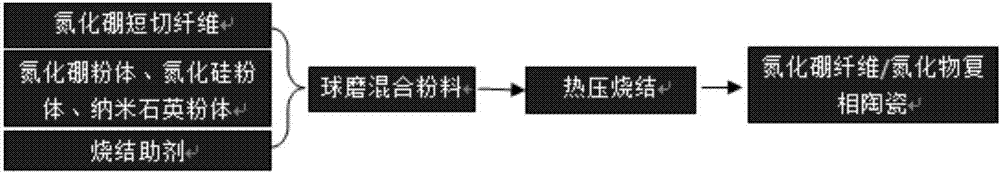

[0029] Such as figure 1 As shown, the boron nitride fiber is first cut into short fibers with a length of 5 mm, and then ball milled with a fast mill, and the fiber length-to-diameter ratio after ball milling is controlled to be 15;

[0030] Weigh the nitride powder according to the proportion of each substance, and the mass ratio of BN powder: Si 3 N 4 Powder = 1:9, plus 3% of the nitride powder quality of the sintering aid alumina, nitride powder and 3% of the total mass of the sintering aid nano-SiO 2 Powder, ethanol dispersion, adding 3% boron nitride short fiber of all powder mass, the mass ratio of the total mass of all the above components to ethanol is 1:2.5, the material of the grinding ball is silicon nitride ball, the total mass of all the above components and the mass ratio of the grinding The mass ratio of the balls is 1:1.5, the mixture is put into a ball mill jar and milled on a rolling mill for 3 hours at a speed of 170 rpm;

[0031] The slurry after mixing ...

Embodiment 2

[0035] First cut the boron nitride fiber into short fibers with a length of 6 mm, and then use a fast mill for ball milling, and control the fiber aspect ratio after ball milling to 17;

[0036] Weigh the nitride powder according to the proportion of each substance, and the mass ratio of BN powder: Si 3 N 4 powder=1:5, plus 7% of the nitride powder quality sintering aid yttrium oxide, nitride powder and 7% nano-SiO of the total mass of the sintering aid 2 Powder, ethanol dispersion, adding 12% boron nitride short fiber of all powder mass, the mass ratio of the total mass of all the above components to ethanol is 1:2.0, the material of the grinding ball is silicon nitride ball, the total mass of all the above components and the mass ratio of the grinding The mass ratio of the balls is 1:1, the mixture is put into a ball mill jar and ball milled on a rolling mill for 8 hours at a speed of 150 rpm;

[0037] The slurry after mixing and ball milling is put into a drying box for d...

Embodiment 3

[0041] First cut the boron nitride fiber into short fibers with a length of 7mm, and then use a fast mill for ball milling, and control the fiber aspect ratio after ball milling to 20;

[0042]Weigh the nitride powder according to the proportion of each substance, and the mass ratio of BN powder: Si 3 N 4 Powder=1:1, plus 3% nitride powder mass of sintering aids, a mixture of alumina and yttrium oxide, 12% of the total mass of nitride powders and sintering aids, nano-SiO 2 Powder, ethanol dispersion, adding 20% boron nitride short fiber of all powder mass, the mass ratio of the total mass of all the above components to ethanol is 1:1.8, the material of the grinding ball is silicon nitride ball, the total mass of all the above components and the mass ratio of the grinding The mass ratio of the balls is 1:1.3, the mixture is put into a ball mill jar and milled on a rolling mill for 3 hours at a speed of 190 rpm;

[0043] The slurry after mixing and ball milling is put into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com