Method for preparing 3-aminophthalic acid

A technology of aminophthalic acid and nitrophthalic acid, which is applied in the preparation of organic compounds, chemical instruments and methods, and the preparation of cyanide reactions, etc., which can solve the problems of large environmental pollution, high cost, and high risk , to achieve the effect of good product purity, low production cost and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

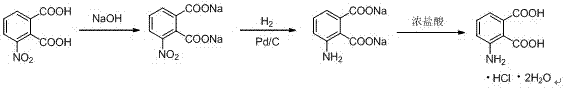

Image

Examples

Embodiment 1

[0014] (1) Add 65g of purified water to a 200mL beaker, add 3.79g of NaOH and stir to dissolve, cool to room temperature (25-35°C), add 3-nitrophthalic acid (10g), stir to dissolve;

[0015] (2) Add the above 3-nitrophthalic acid solution into a 2L hydrogenation kettle, add 0.5g of palladium carbon, start stirring, replace the air with nitrogen, and then replace the nitrogen with hydrogen, and keep the hydrogen pressure at 0.7-0.9Mpa, Keep the temperature of the reaction solution at 55-65°C for hydrogenation. The reaction takes about 12h;

[0016] (3) After the reaction is over, replace the hydrogen with nitrogen, and filter out the palladium carbon;

[0017] (4) Pour the filtrate into a 2L flask, lower the temperature to -5-0°C, add about 18.8mL of concentrated hydrochloric acid dropwise, keep the temperature at -5-5°C, and drop it for about 30 minutes. After the dropwise addition, keep stirring for 0.5 h;

[0018] (5) Suction filter and rinse twice with ethyl acetate. Th...

Embodiment 2

[0020] (1) Add 65kg of purified water to a 200L enamel kettle, add 3.79kg of NaOH and stir to dissolve, cool to room temperature (25-35°C), add 3-nitrophthalic acid (10kg), stir and dissolve, then transfer to turnover in the barrel;

[0021] (2) Take about 20L of the above solution, disperse palladium carbon (dry weight 0.5kg) in it, pump it into a 200L hydrogenation kettle by vacuum, and then pump the remaining 3-nitrophthalic acid solution into a 200L hydrogenation kettle by vacuum In the kettle, start stirring, replace the air with nitrogen, and then replace the nitrogen with hydrogen, keep the hydrogen pressure at 0.7-0.9Mpa, and keep the temperature of the reaction solution at 55-65°C for hydrogenation. The reaction takes about 12h;

[0022] (3) After the reaction is over, replace the hydrogen with nitrogen, remove the palladium carbon by filtering with a sand filter rod filter, filter again with a filter added with diatomaceous earth, and vacuum the filtrate into a 200L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com