A kind of surface multifunctional coating and its preparation method and application

A kind of chemical coating and multi-functional technology, applied in the field of analytical chemistry, can solve the problems of anti-non-specific adsorption performance damage, etc., and achieve the effect of strong tolerance, good stability and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

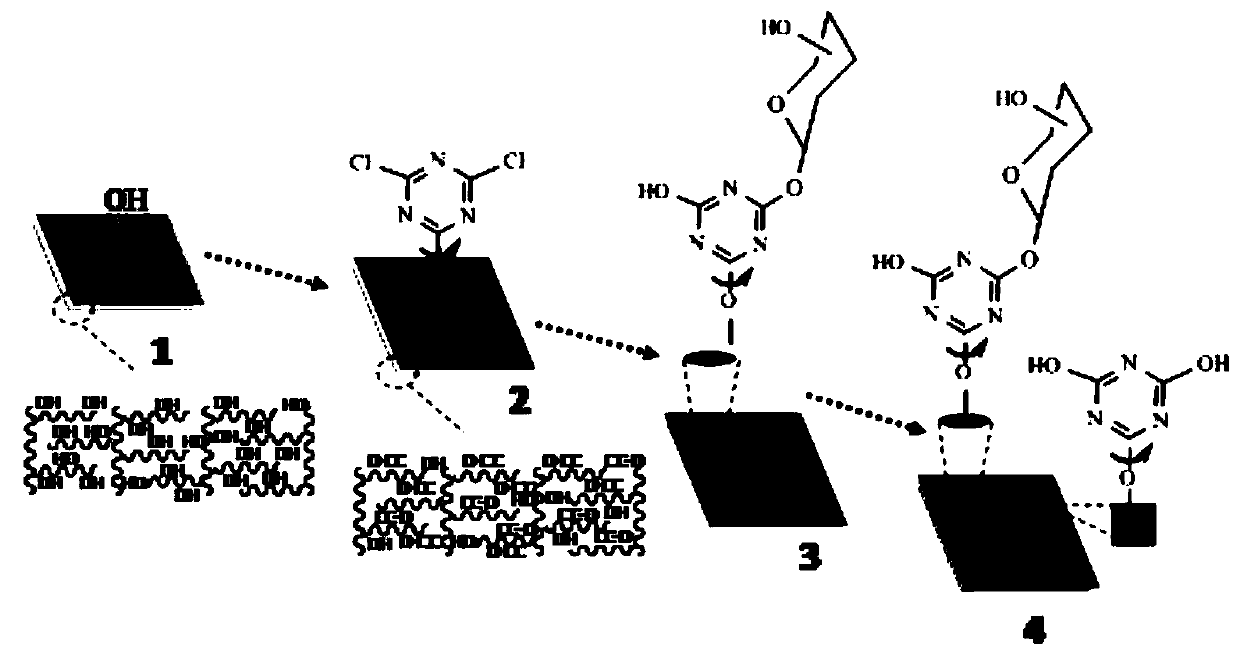

[0061] to immobilize glucose and chicken ovalbumin (e.g. figure 1 shown), the specific preparation steps are as follows:

[0062] 1. Preparation of a functionalized layer with glucose and chicken ovalbumin on the surface of gold membrane

[0063] 1. In situ modification initiator of gold film surface

[0064] Soak the gold film in 10mmol / L, 0.75mL ethanol solution of mercaptoundecanol (MUOH), react at 4°C for 12h, wash with ethanol three times, and blow dry with nitrogen. The gold film was placed in a suitable reactor, 1 mL of tetrahydrofuran (13.7 mmol) and 84 μL of pyridine (1.0 mmol) were added, and 124 μL of 2-bromoisobutyryl bromide (BIBB,) (1.0 mmol) was added dropwise. React at room temperature at 25°C for 30 minutes, wash the gold film with THF three times, and dry it with nitrogen.

[0065] 2. In-situ polymerization of polyhydroxyethyl methacrylate (pHEMA, molecular weight about 30,000) on the surface of the gold film

[0066] The in situ polymerization of pHEMA n...

Embodiment 2

[0076] Lysine is immobilized on the glass surface, and the preparation steps of the specific functionalized layer are as follows:

[0077] 1. Preparation of functionalized layer with lysine on glass surface

[0078] 1. In situ modification initiator of glass surface

[0079] After plasma cleaning (70W, 3min), the glass substrate was immediately immersed in 0.75mL, 3% (mass fraction) 3-amino-trimethoxysilane (ATPMS) toluene solution to react for 30min, and then ultrasonically cleaned with toluene and acetone for 3 times respectively. , blow dry with nitrogen. The gold film was placed in a suitable reactor, (13.7 mmol) tetrahydrofuran and 1.0 mmol) pyridine were added, and 1.0 mmol 2-bromoisobutyryl bromide (BIBB) was added dropwise. After reacting for 30 minutes, the glass substrate was washed three times with tetrahydrofuran, and dried with nitrogen.

[0080] 2. In situ polymerization of pHEMA on the glass surface

[0081] The in situ polymerization of pHEMA needs to be ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com