Method for extracting isoflavone from soybean

A technology for isoflavones and isoflavone glycosides is applied in the field of high-purity isoflavone products, which can solve the problems of unsuitable full-fat soybean powder extraction, undiscovered medicinal value, and methanol harmful to human health, etc., and achieves easy regeneration and simple operation. , the effect of high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

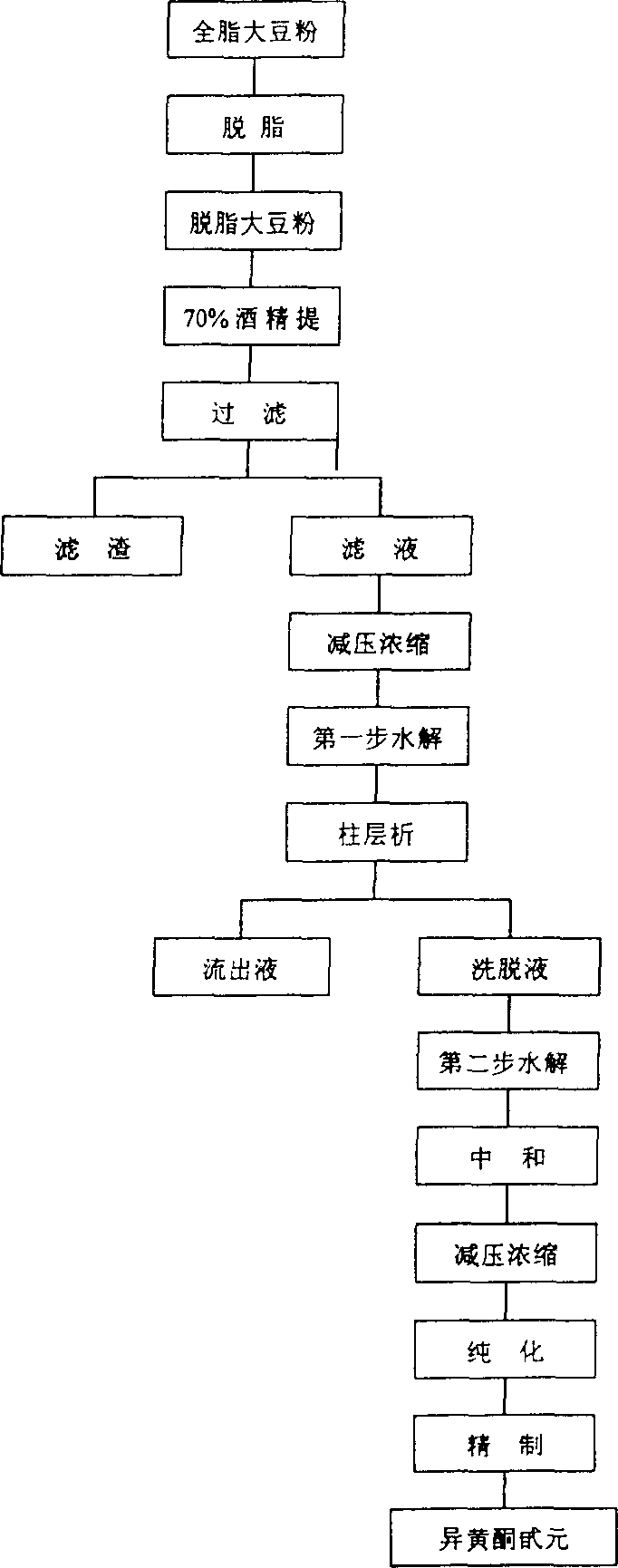

[0070] Embodiment 1 technological process is with reference to appendix figure 1 .

[0071] The present invention uses 1000 grams of soybean flour (full-fat soybean flour), puts it into a 5000ml Soxhlet fat extractor after packing it with a filter cloth bag, and takes out the filter cloth bag after refluxing with 5000ml n-hexane on a 75° C. water bath for 8 hours, and waves to remove the residue The normal hexane is the defatted soybean meal.

[0072] Weigh 1000 grams of defatted soybean powder, put it into a 10000ml flask, add 6000ml of 70% alcohol and 0.3% acetic acid mixed extract, stir and extract at room temperature for 2 hours, then filter, and wash the filter residue three times with a small amount of new extract. The filtrate was concentrated under reduced pressure at 65°C to 1000ml, and then hydrolyzed in a water bath at 80°C for 15 hours (the first step of hydrolysis), and all the malonyl isoflavone glycosides were hydrolyzed into isoflavone glycosides. After the h...

Embodiment 2

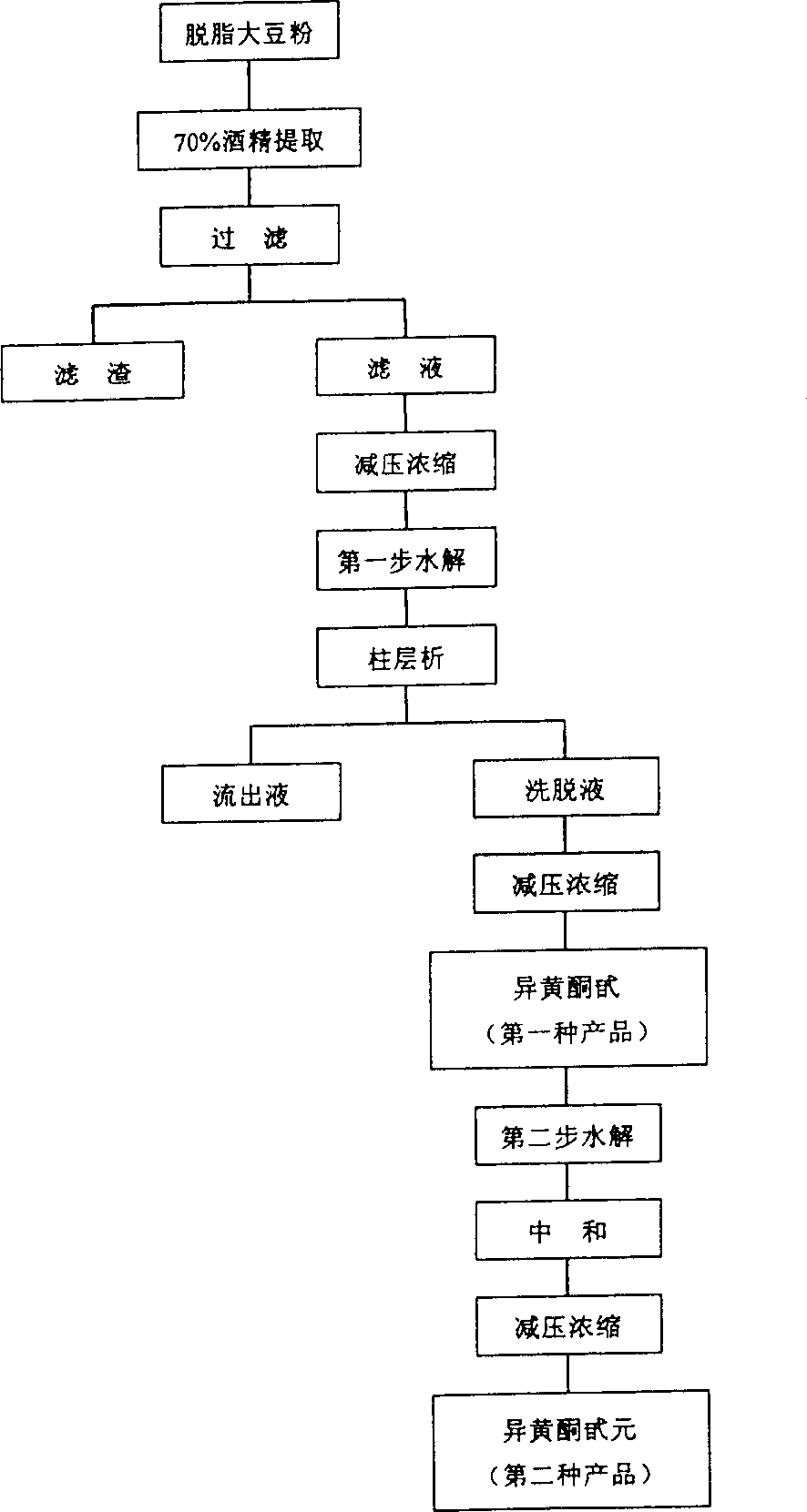

[0081] Embodiment 2 technological process is with reference to appendix figure 2

[0082] Weigh 1000 grams of defatted soybean powder, put it into a 10000ml flask, add 6000ml of 70% alcohol and 0.3% acetic acid mixed extract, stir and extract at room temperature for 2 hours and then filter. The filter residue was washed three times with a small amount of new extract, and the filtrate was concentrated under reduced pressure at 65°C to 1000ml, and then hydrolyzed in a water bath at 80°C for 15 hours (the first step of hydrolysis), and all malonyl isoflavone glycosides were hydrolyzed into isoflavone glycosides. After the hydrolyzate is cooled, it passes through a φ3.0×50cm polyamide chromatography column at a flow rate of 5-10ml / min. After the hydrolyzate has run out, rinse the column with water until the effluent is a colorless transparent liquid, and stop rinsing. The chromatography column was eluted with 500ml (about twice the column volume) of 70% alcohol. The received 5...

Embodiment 3

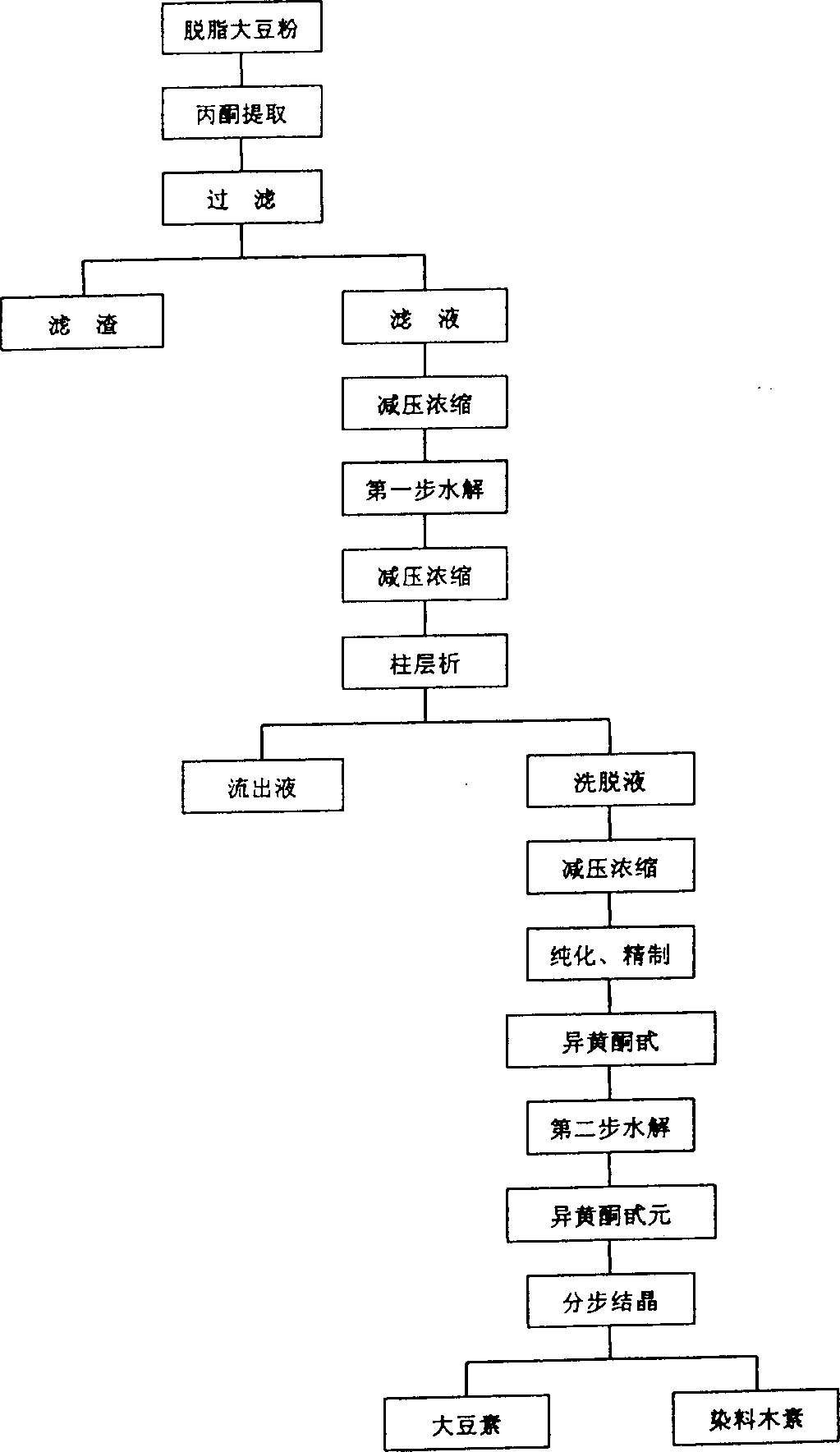

[0085] Embodiment 3 technological process is with reference to appendix image 3 .

[0086]Weigh 1000 grams of defatted soybean powder, put it into a 10000ml flask, add 5000ml of acetone and 0.1M acetic acid mixed extract, stir and extract at room temperature for 2 hours, then filter, and wash the filter residue three times with a small amount of mixed extract. The filtrate was concentrated to dryness at 40°C under reduced pressure, added 500ml of 50% alcohol to dissolve the solid, and hydrolyzed in a water bath at 80°C for 15 hours. The hydrolyzed product was isoflavone glycosides. Concentrate under reduced pressure at 65°C until alcohol-free. The suspension passes through a φ3.0×50cm polyamide chromatography column at a flow rate of 5ml / min, and the column is rinsed with water after the suspension is exhausted until the effluent is a colorless transparent liquid. The chromatography column was eluted with 500ml (about twice the column volume) of 70% alcohol. The received 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com