Stainless steel flux cored wire

A technology of flux-cored welding wire and stainless steel, applied in welding equipment, welding medium, welding equipment, etc., can solve the problems of insufficient strength characteristics, high cost, high alloy content, and achieve good slag peelability and good tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14 and comparative example 1~10

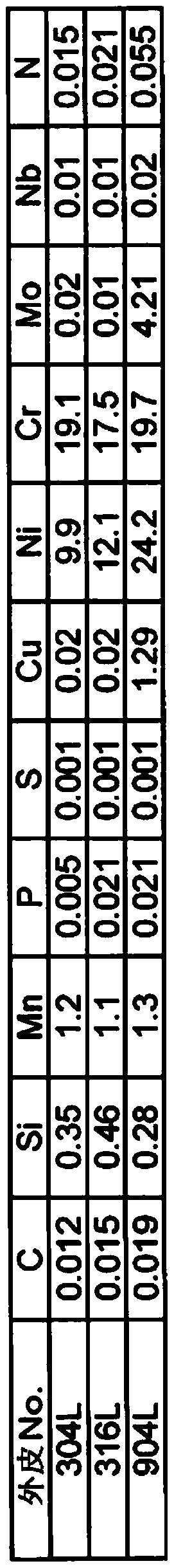

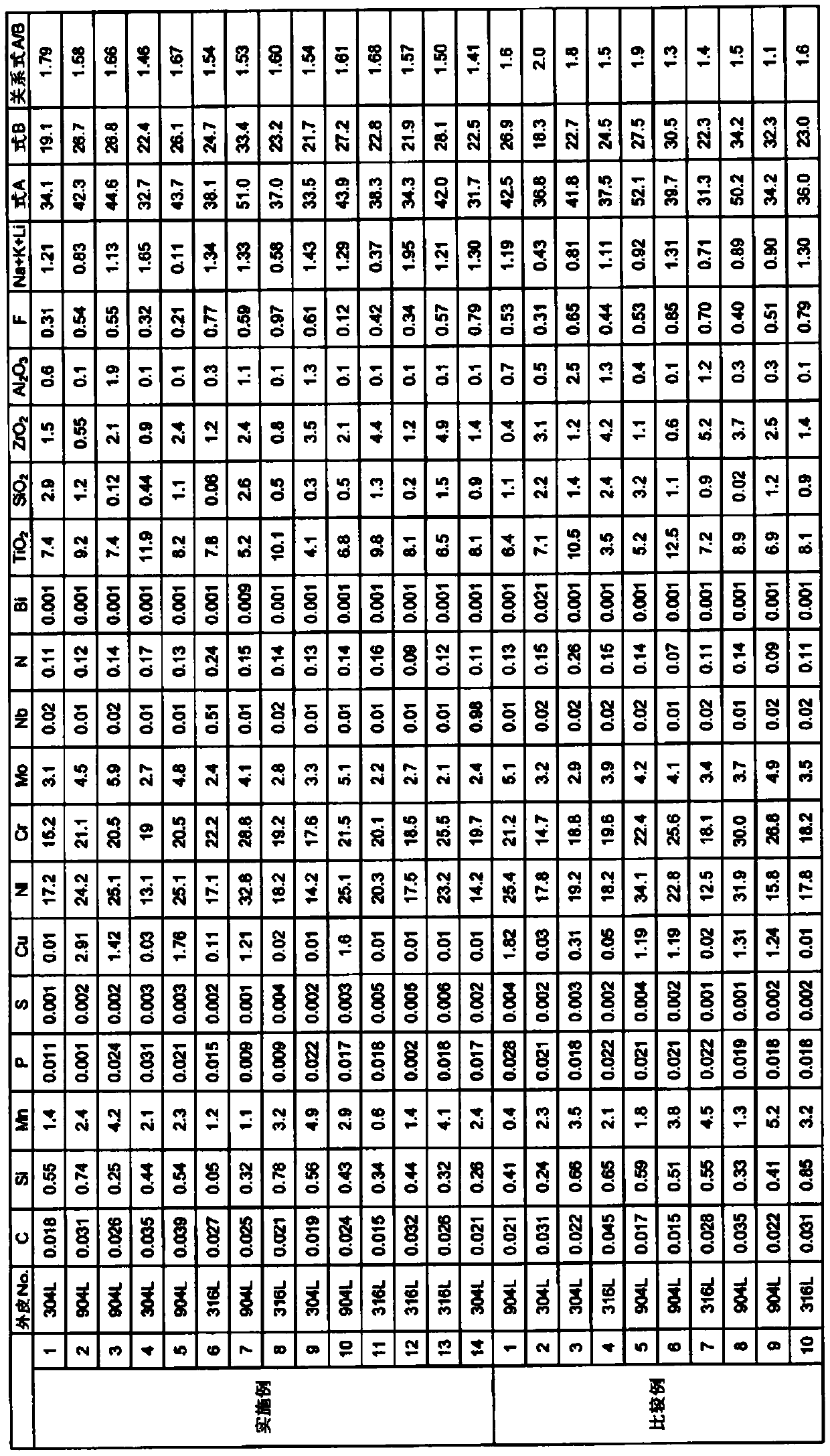

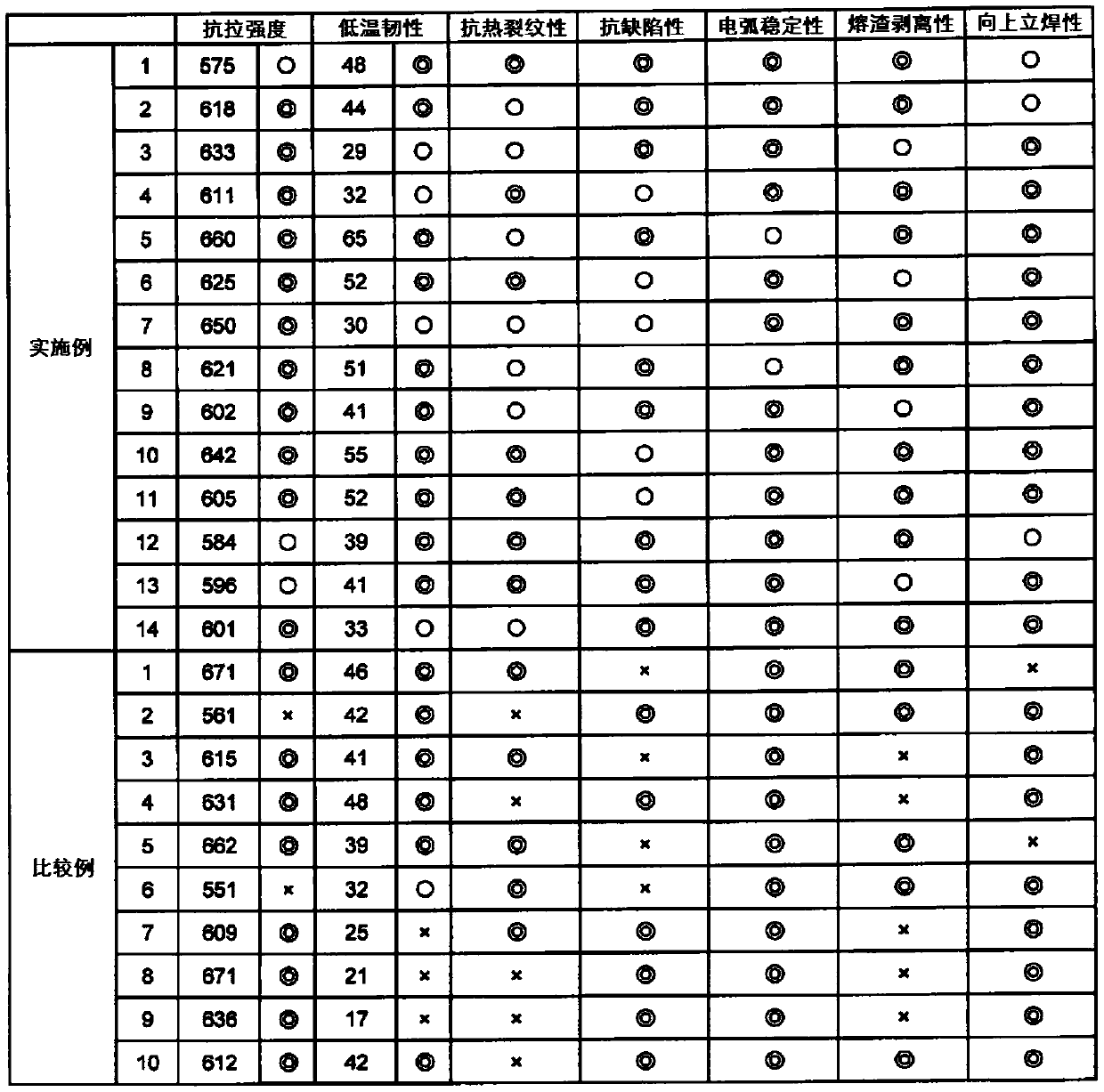

[0125] Flux-cored welding wires having the chemical compositions shown in Table 2 were produced using sheaths having the chemical compositions shown in Table 1.

[0126] The wire diameters of the obtained flux-cored wires were all 1.2 mm, and the flux rate was 21 to 34% by mass.

[0127] In addition, the chemical compositions in Table 1 and Table 2 are expressed in mass % relative to the total mass of the welding wire. In addition, "Bi" means a Bi-converted value for a Bi compound, "F" means a fluorine-converted value for a fluoride, and "Na+K+Li" means an alkali metal compound composed of Na, K, and Li. The sum of the alkali metal conversion values. In addition, the so-called "formula A" is the value represented by [Ni+30×(C+N)+0.5×Mn+12.4] among the contents of each component contained in the welding wire, and the so-called "formula B" is the content of each component contained in the welding wire. Among the contents of each component, the value represented by [Cr+Mo+1.5×S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com