Unpowered biogas production device capable of automatically stirring and recycling feed liquid

A technology of automatic stirring and production equipment, which is applied in the fields of waste fuel, biological sludge treatment, biological water/sewage treatment, etc. The effect of improving quality, increasing consistency, and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

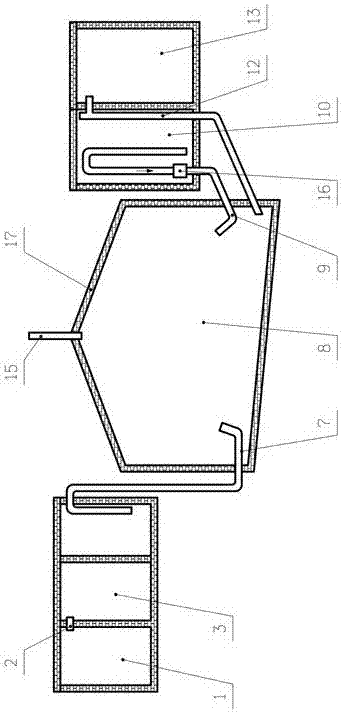

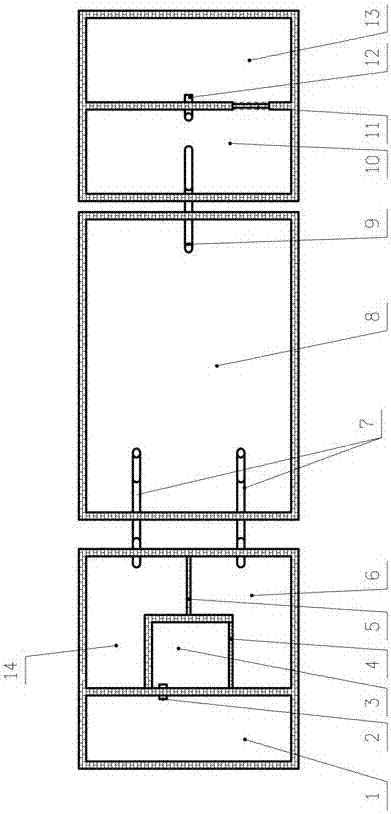

[0015] As shown in Figures 1 to 2, a biogas production device according to the present invention, which can automatically stir without power and recycle feed liquid, includes a U-shaped solid-liquid separation tank, a biogas tank, a biogas residue tank and a biogas slurry tank.

[0016] The bottom of the biogas pool according to the present invention is in the shape of a rectangle with high left and right bottom, a gable roof is arranged on the upper part, and a biogas pipe is arranged in the middle of the top of the gable roof. The construction of the biogas pool body can be assembled with glass fiber reinforced plastics, bricks, concrete pouring or other new materials. The size of the pool body and supporting facilities and equipment can be increased or reduced in proportion according to the raw materials and the actual situation of the site.

[0017] The solid-liquid separation pool of the present invention includes a coarse slag pool, a fine slag pool, a membrane filtration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com