Remediator and preparation method thereof and restoration method for heavy metal contaminated soil thereby

A technology for polluted soil and heavy metals, applied in the field of soil remediation, can solve the problems of insignificant effect, small biomass, slow growth, etc., and achieve the effect of reducing the degree of heavy metal pollution, increasing the content of organic matter, and improving soil fertility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

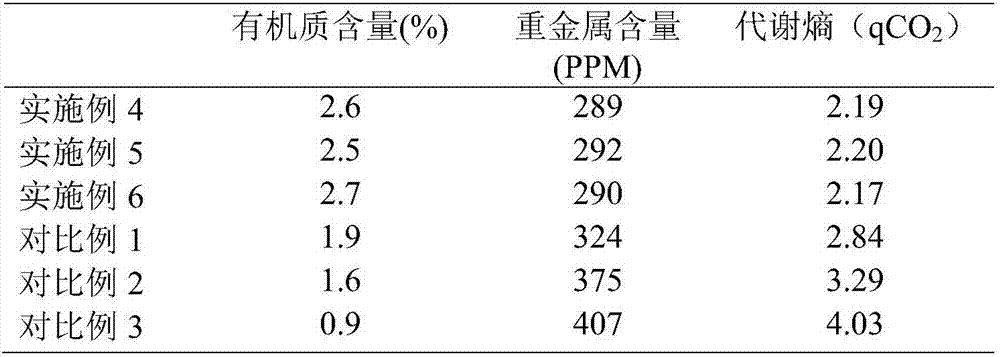

Examples

Embodiment 1

[0039] Mix 30 parts of corn stalk charcoal, 7 parts of calcium carbonate, 6 parts of dolomite, and 6 parts of bentonite according to the weight ratio, and mix well to obtain the mixture I; turn over the mixture I, add water, and stop for 10 days Turn over the pile to obtain mixture II; add 1 part of Trichoderma to the mixture II, stir and mix, then add 5 parts of atomized wood vinegar, and mix evenly. Then, it is pulverized and granulated to obtain a remediation agent for remediating heavy metal-contaminated soil. Wherein, the wood vinegar is crude wood vinegar diluted 300 times.

Embodiment 2

[0041] Mix 40 parts of cotton stalk charcoal, rice husk charcoal and cow dung charcoal, 4 parts of calcium carbonate, 4 parts of dolomite, and 5 parts of bentonite according to the proportion by weight, and mix evenly to obtain the mixture I; Turn the heap, add water, stop turning the heap after 12 days, and obtain the mixture II; add 0.6 parts of Trichoderma to the mixture II, stir and mix, then add 3.5 parts of atomized wood vinegar, and mix evenly. Then, it is pulverized and granulated to obtain a remediation agent for remediating heavy metal-contaminated soil. Wherein, the wood vinegar is crude wood vinegar diluted 400 times.

Embodiment 3

[0043] Mix 60 parts of cotton stalk charcoal and rice husk charcoal, 2 parts of calcium carbonate, 3 parts of dolomite, and 4 parts of bentonite according to the proportion by weight, and mix well to obtain the mixture I; turn over the mixture I, add water , 15 days to stop turning, to obtain mixture II; add 0.2 parts of Trichoderma to the mixture II, stir and mix, then add 2 parts of atomized wood vinegar, and mix evenly. Then, it is pulverized and granulated to obtain a remediation agent for remediating heavy metal-contaminated soil. Wherein, the wood vinegar is crude wood vinegar diluted 500 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com