Al-Mg2Si-based composite and preparation method thereof

A composite material and matrix technology, which is applied in the field of metal materials, can solve the problem that high temperature performance needs to be improved, and achieve the effects of improving high temperature performance and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Raw materials are prepared according to the following mass percentages: 72.5% pure aluminum, 9.5% pure magnesium, 5.5% pure silicon, 7.5% aluminum-copper master alloy, 5% aluminum-nickel master alloy, wherein the aluminum-copper master alloy contains The amount of copper is 20% and the nickel content of the aluminum-nickel master alloy is 10%;

[0022] (2) Melt pure aluminum to 750°C in a melting furnace, add pure silicon first, stir for 5 minutes after it is completely melted, and then press pure magnesium into the bottom of the melt for 10 minutes when the temperature drops to 600°C, then add 0.5wt. %C 2 C1 6 Degassing and slag removal;

[0023] (3) Increase the temperature to 750° C., add 10% aluminum-copper master alloy and 10% aluminum-nickel master alloy, keep warm and stir for 10 minutes, and then cast into an ingot.

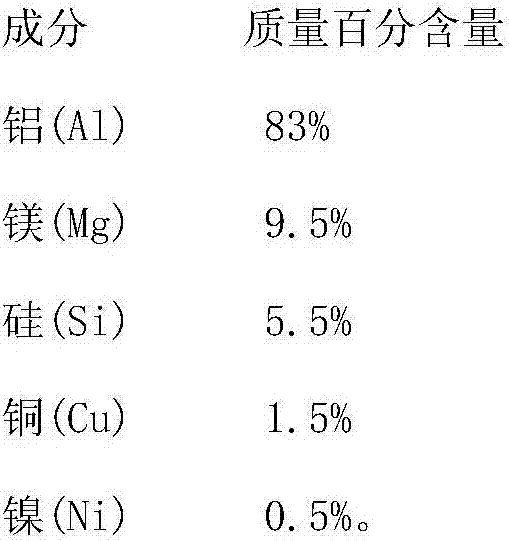

[0024] Prepared Al 3 CuNi reinforced Al-Mg 2 The composition of the Si-based composite material is:

[0025]

Embodiment 2

[0027] (1) Raw materials are prepared according to the following mass percentages: 75% pure aluminum, 9.5% pure magnesium, 5.5% pure silicon, 10% aluminum-copper master alloy, 10% aluminum-nickel master alloy, wherein the aluminum-copper master alloy contains The amount of copper is 30% and the nickel content of the aluminum-nickel master alloy is 10%;

[0028] (2) Melt pure aluminum to 800°C in a smelting furnace, add pure silicon first, stir for 10 minutes after it is completely melted, and then press pure magnesium into the bottom of the melt for 10 minutes when the temperature drops to 650°C, then add 0.5wt. %C 2 C1 6 Degassing and slag removal;

[0029] (3) Then raise the temperature to 800° C., add 7.5% aluminum-copper master alloy and 5% aluminum-nickel master alloy, keep warm and stir for 20 minutes, and then cast into an ingot.

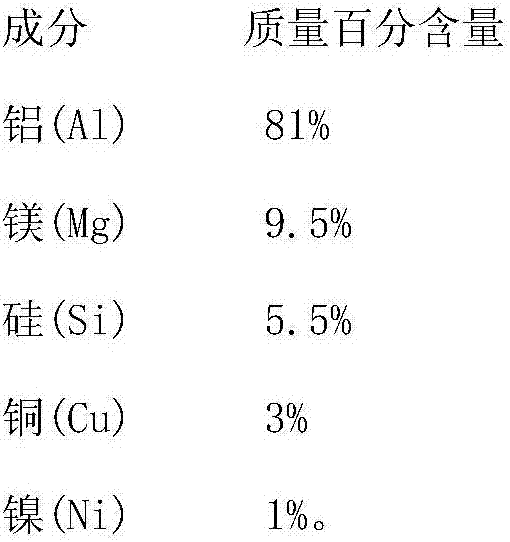

[0030] Prepared Al 3 CuNi reinforced Al-Mg 2 The composition of the Si-based composite material is:

[0031]

Embodiment 3

[0033] (1) Prepare raw materials according to the following mass percentages: 62.5% pure aluminum, 9.5% pure magnesium, 5.5% pure silicon, 15% aluminum-copper master alloy, 7.5% aluminum-nickel master alloy, wherein the aluminum-copper master alloy contains The amount of copper is 30% and the nickel content of the aluminum-nickel master alloy is 20%;

[0034] (2) Melt pure aluminum to 800°C in a smelting furnace, add pure silicon first, stir for 10 minutes after it is completely melted, and then press pure magnesium into the bottom of the melt for 10 minutes when the temperature drops to 650°C, then add 0.5wt. %C 2 C1 6 Degassing and slag removal;

[0035] (3) Raise the temperature to 850° C., add 15% aluminum-copper master alloy and 7.5% aluminum-nickel master alloy, keep warm and stir for 30 minutes, then cast into an ingot.

[0036] Prepared Al 3 CuNi reinforced Al-Mg 2 The composition of the Si-based composite material is:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com