Manufacturing method of novel electricity-saving composite anode plate for copper-zinc electrolysis and electrodeposition

A composite anode and anode plate technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of increasing metal hardness, crystallization compactness, etc., and achieve the effect of improving excellent conductivity, good conductivity, and reducing cell voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

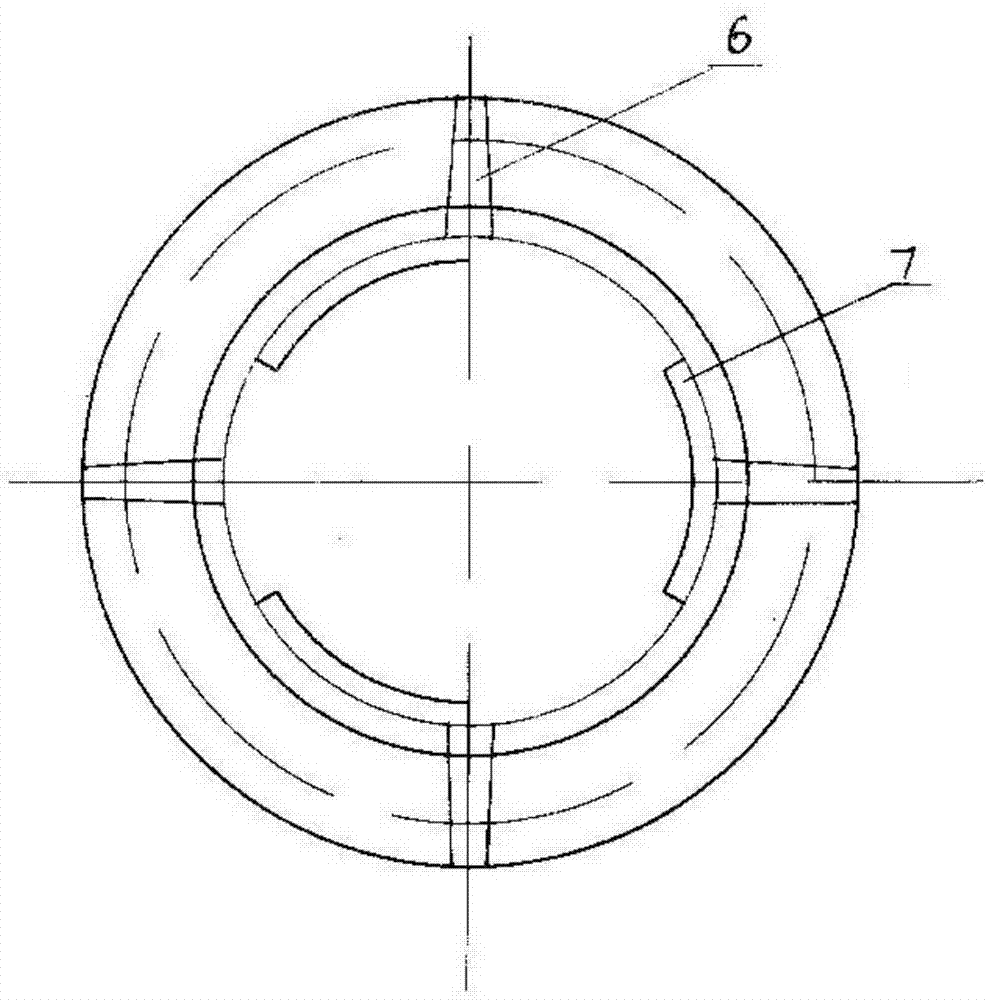

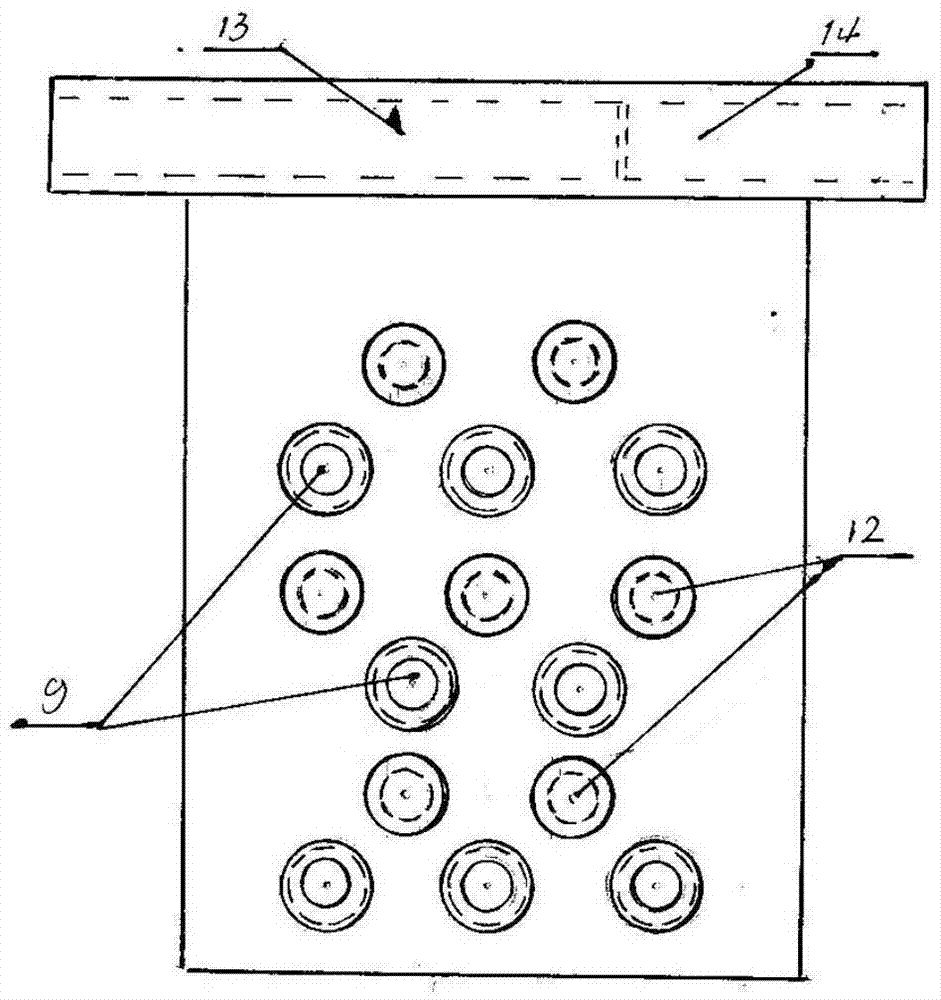

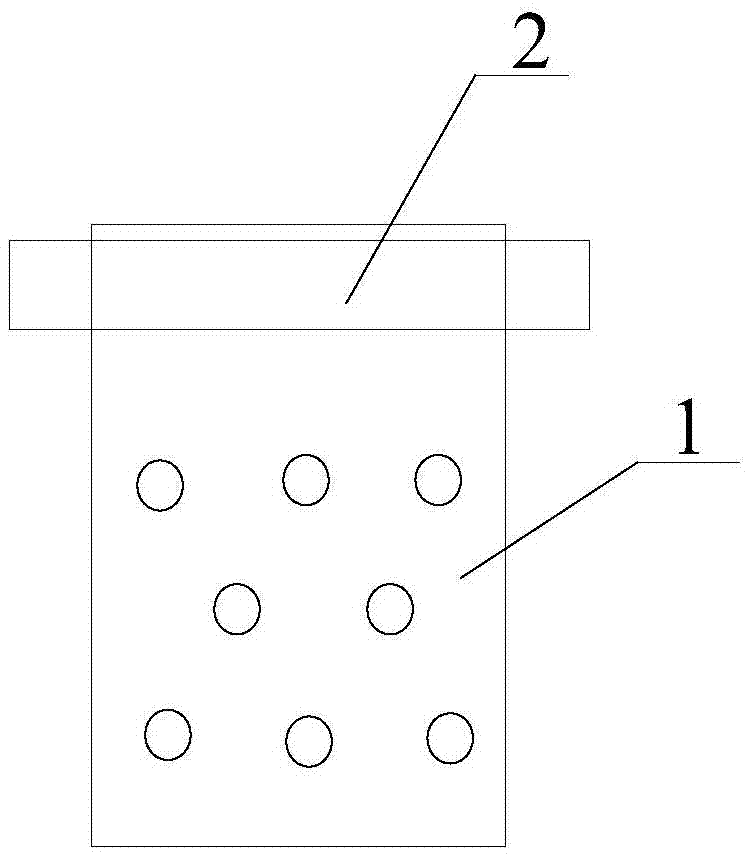

[0023] Depend on Figure 1-8 It can be seen that the plate body is a three-layer plate, the middle layer of the three-layer anode plate is copper or aluminum sheet (including aluminum alloy and titanium and titanium alloy, titanium coating sheet), and the outer layer is lead plate.

[0024] In the three-layer anode plate, the thickness of the aluminum sheet is 0.5-3mm, and the thickness of the lead plate is 1-3mm.

[0025] The three plates of the three-layer anode plate adopt one or more of the following six composite methods; 1. The inner single plate body is stamped to form a through circular and rectangular hole, inserted into the vertical casting mold, and poured into the melting point The lower lead liquid wraps the inner interlayer densely, rolls it to the thickness required by the process design, and punches the overflow hole to form a composite plate. 2. Stamping or drilling methods (including circular and rectangular holes) penetrate the three-layer board body, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com