Coating structure, heat exchanger, and method for manufacturing heat exchanger

A heat exchanger and coating technology, which is applied in the manufacture of heat exchangers and heat exchangers, and in the field of coating structure, can solve the problems of atomic layer deposition method surface reaction hindrance, poor formation of insulating film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

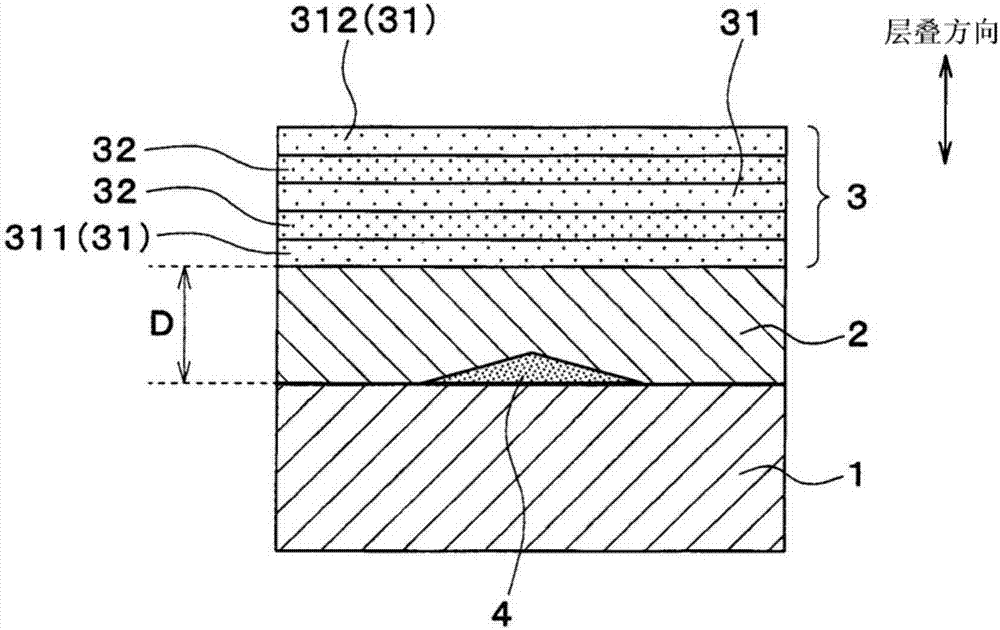

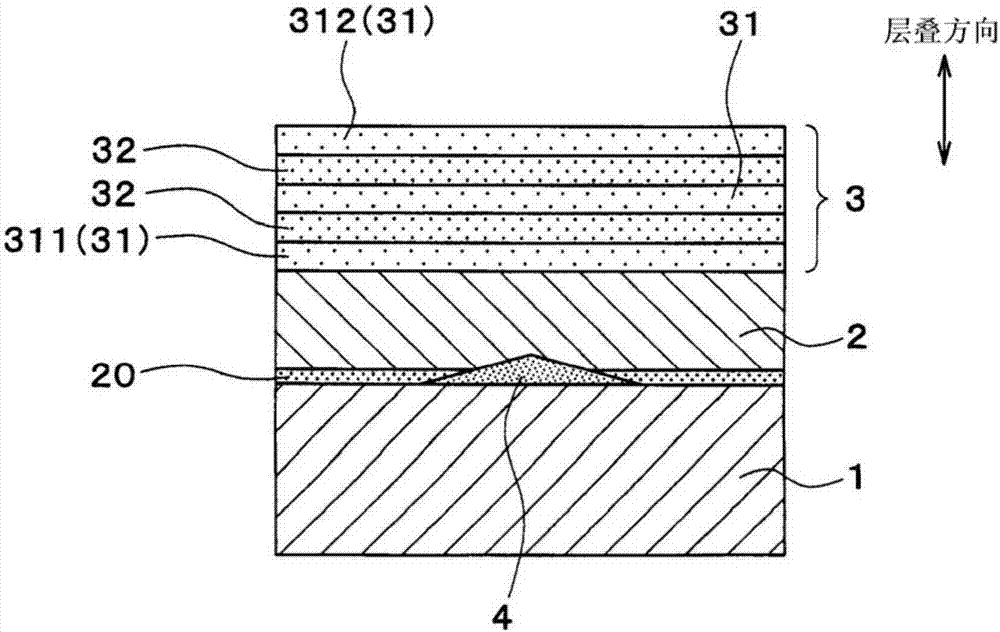

[0027] Below, based on figure 1 and figure 2 A first embodiment of the present invention will be described. In this embodiment, an example in which the coating structure of the present invention is applied to an exhaust pipe through which exhaust gas from an internal combustion engine flows will be described.

[0028] Such as figure 1 As shown, the exhaust pipe is formed with a base material 1 made of metal. In this embodiment, the base material 1 is formed of stainless steel or aluminum.

[0029] A substrate 2 is formed above the substrate 1 , that is, on the surface of the substrate 1 . An insulating film 3 is formed above the base 2 , that is, on the surface of the base 2 opposite to the substrate 1 .

[0030] The base 2 improves the adhesion between the base material 1 and the insulating film 3 . The substrate 2 of the present embodiment is made of amorphous silicon carbide (SiC) or aluminum oxide (Al 2 o 3 ) composed of a monolayer film. In addition, the thickne...

no. 2 approach

[0056] Next, based on Figure 5 A second embodiment of the present invention will be described. This second embodiment differs from the first embodiment in the structure of the base 2 .

[0057] Such as Figure 5 As shown, the substrate 2 of the present embodiment is formed by alternately stacking a plurality of amorphous layers 21 made of amorphous and crystalline layers 22 made of crystalline crystals. In the base 2 , an amorphous layer 21 is arranged at a portion in contact with the base material 1 and a portion in contact with the insulating film 3 . That is, in the base 2 , the portions in contact with the base material 1 and the portions in contact with the insulating film 3 are respectively amorphous.

[0058] As described above, in the base 2 , the portion in contact with the base 1 is made amorphous, so that the adhesiveness between the base 1 and the base 2 can be improved. In addition, in the base 2 , the portion in contact with the insulating film 3 is made amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com