Method for immobilizing Thermomyces lanuginosus lipase

A technology of thermomyces and lipase, which is applied in the direction of fixing on/in the organic carrier, can solve the problems of high price and insufficient chemical methods of commercial lipase, and achieve convenient operation and simple preparation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 100ml of liquid lipase Lipozyme TL 100L (Thermomyces lanuginosa lipase, Novozymes, Denmark) to 400ml of tert-butanol at 4°C, let it settle for 1 hour, and centrifuge at 10,000rpm for 10 minutes. Remove the supernatant, add 20g of non-polar macroporous adsorption resin D101 and 20ml of crosslinking agent (5% polyethyleneimine aqueous solution) for precipitation, shake the shaker for 2 hours, and then dry the reaction solution in vacuum at 45°C for 4 hours , to prepare 9.96 g of immobilized lipase. The esterification activity of the immobilized lipase was measured, and the specific enzyme activity was 3580U / g.

[0027] The definition and determination method of the esterification activity unit of immobilized lipase are as follows:

[0028] Definition of lipase esterification activity (U): the amount of enzyme required to generate 1 μmoL of the product methyl oleate per minute at 50°C. The specific enzyme activity is calculated as follows: X=[V×(V1 / V2)]ρ / [(m T) M]

...

Embodiment 2

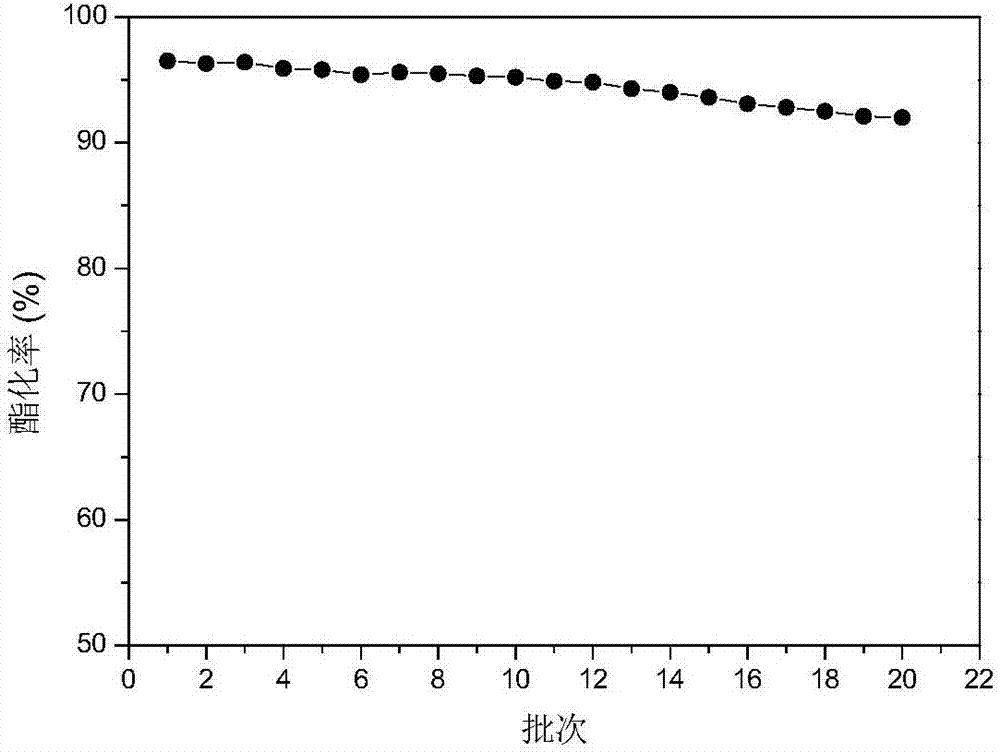

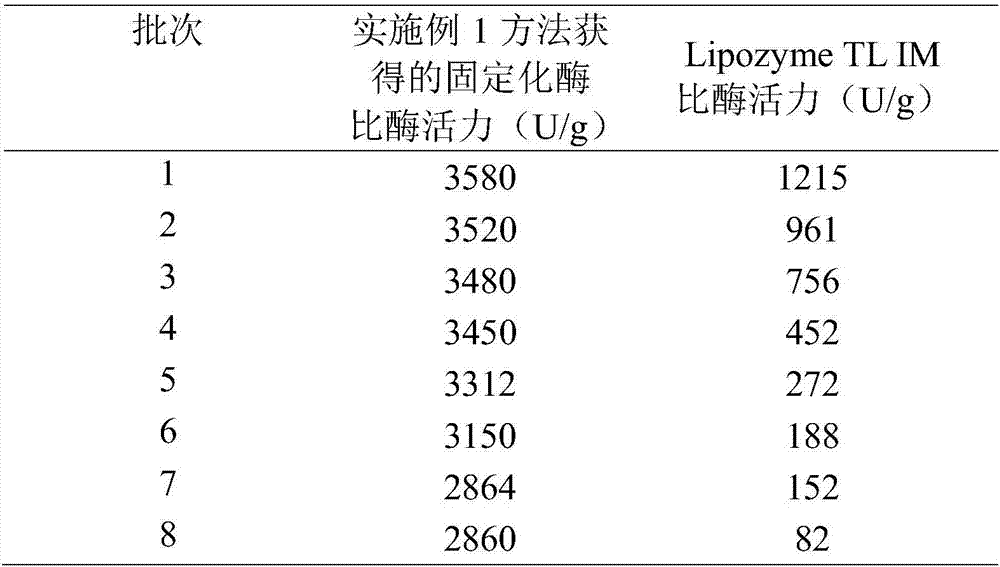

[0033] Prepare different batches of immobilized lipase according to the method of Example 1, and use the esterification activity of different batches of commercial liquid lipase Lipozyme TL 100L as a control to obtain the batch stability comparison results of immobilized lipase, as shown in Table 1 The results showed that the enzyme activity and stability of the self-made immobilized lipase were much higher than the commercial enzyme Lipozyme TL IM.

[0034] Table 1: The stability comparison results of the immobilized lipase prepared in Example 1 and commercialized enzyme

[0035]

Embodiment 3

[0037] The organic solvent of Example 1 is changed to that shown in Table 1, and other conditions are unchanged. The esterification activity of the obtained immobilized lipase was determined, and the results are shown in Table 2.

[0038] Table 2: Specific enzyme activity results of precipitation with different organic solvents

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com