Deacidification liquid having paper strengthening effect and preparation method thereof

A technology of enhancement and deacidification, applied in the post-processing of waste paper, etc., can solve the problems of reduced paper strength, difficulty in drying, safety restrictions, etc., and achieve the effect of mild nature and no damage to handwriting and color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Composition of deacidification solution: Mg 2 Al-LDHs (structural formula is [Mg 4 al 2 (OH) 12 ](CO 3 )·4H 2 O), the non-ionic surfactant nonylphenol polyoxyethylene ether, the paper strengthening agent is chlorine-modified starch, and the solvent is perchlorethylene.

[0028] Preparation of deacidification solution: 0.34g of Mg with a diameter of 50nm 2 Al-LDHs, 0.2g modified starch, 0.17g nonylphenol polyoxyethylene ether and 250g perchlorethylene were mixed and ultrasonicated for 0.5h.

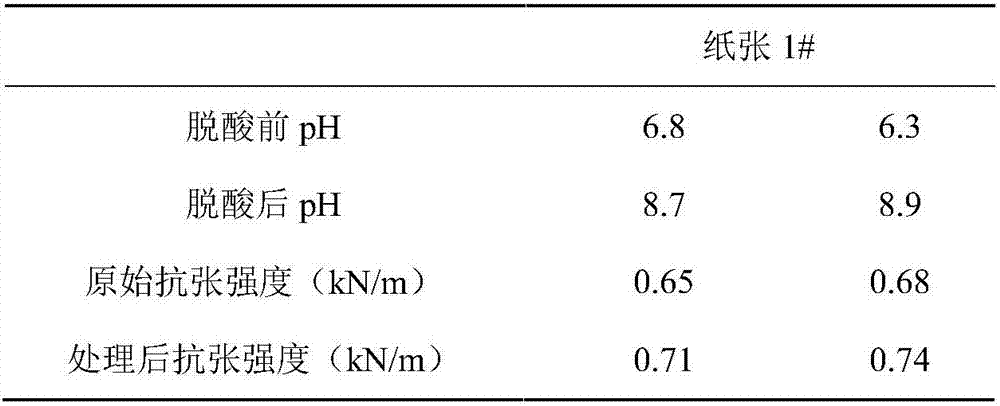

[0029] Process and effect of paper deacidification treatment: Take 20 sheets of acidified paper and fully soak them in the deacidification solution. After soaking for 0.5h, take out the papers and let them dry naturally in the air. Weigh 2g of dried paper and acidified untreated paper, soak them in a beaker filled with 100mL of distilled water (pH=6.3), shake once in the middle, take out the paper after 1h, and measure the pH value of the soaking solution. Two repetitions wer...

Embodiment 2

[0033] Composition of deacidification solution: Mg 4 Al-LDHs (structural formula is [Mg 8 al 2 (OH) 20 ](CO 3 )·4H 2 O), the surfactant sodium dodecylbenzene sulfonate, the paper strengthening agent is chlorine-modified starch, and the solvent is trichlorotrifluoroethane.

[0034] Preparation of deacidification solution: 0.1g of Mg with a diameter of 100nm 4 Al-LDHs, 0.17g sodium dodecylbenzenesulfonate, 0.5g sodium methyl silicate and 250g trichlorotrifluoroethane were mixed, and mechanically ground for 1 hour.

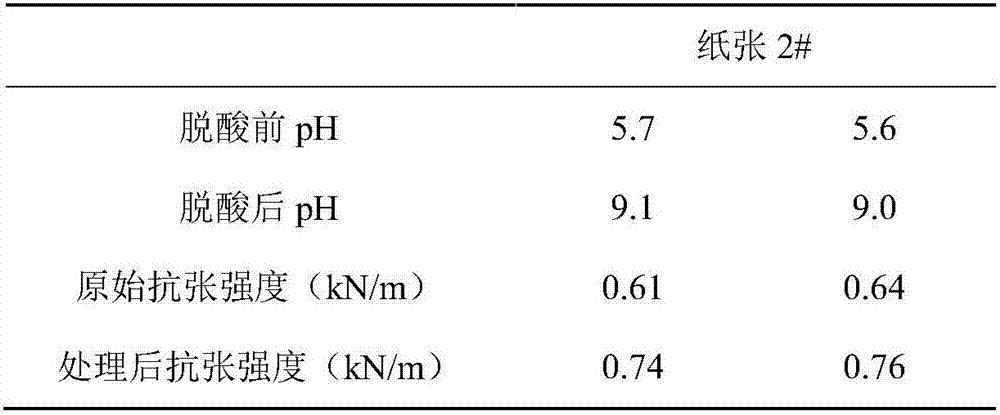

[0035] Process and effect of paper deacidification treatment: Take 20 sheets of acidified paper and fully soak them in the deacidification solution. After soaking for 0.5h, take out the papers and let them dry naturally in the air. Weigh 2g of dried paper and acidified untreated paper, soak them in a beaker filled with 100mL of distilled water (pH=6.3), shake once in the middle, take out the paper after 1h, and measure the pH value of the soaking solution. Two...

Embodiment 3

[0039] Composition of deacidification solution: Mg 10 Al-LDHs (structural formula is [Mg20 al 2 (OH) 44 ](CO 3 )·4H 2 O), the surfactant sodium polyacrylate, the paper strengthening agent is a fluorocarbon-based modified cellulose, and the solvent is 1-fluoro-6-chlorohexane.

[0040] Preparation of deacidification solution: 0.6g of Mg with a diameter of 500nm 10 Al-LDHs, 0.3g of modified cellulose and 0.09g of sodium polyacrylate were mixed with 250g of 1-fluoro-6-chlorohexane, and stirred and mixed by a high-speed disperser for 3 hours.

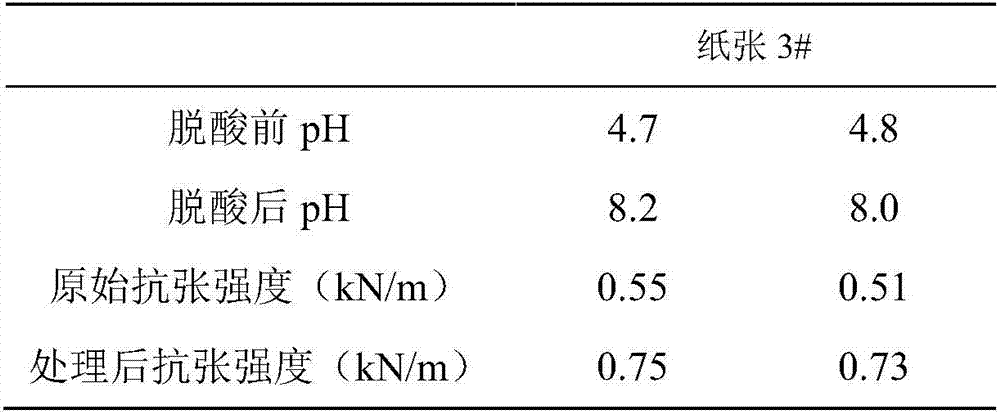

[0041] Process and effect of paper deacidification treatment: Take 20 sheets of acidified paper and fully soak them in the deacidification solution. After soaking for 0.5h, take out the paper,

[0042] And let it dry naturally in the air. Weigh 2g of dried paper and acidified untreated paper, soak them in a beaker filled with 100mL distilled water (pH=6.3), shake once in the middle, take out the paper after 1h, and measure the pH value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com