Watertight and antiseptic power cable and manufacturing method thereof

A technology for power cables and manufacturing methods, which is applied in the field of watertight and anti-corrosion power cables, can solve problems such as inability to meet long-term, stable, reliable, and safe service requirements, insufficient anti-oxidation and anti-corrosion performance, and lack of anti-corrosion capabilities. Stable and timely transmission ability, beneficial to laying, good anti-oxidation and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

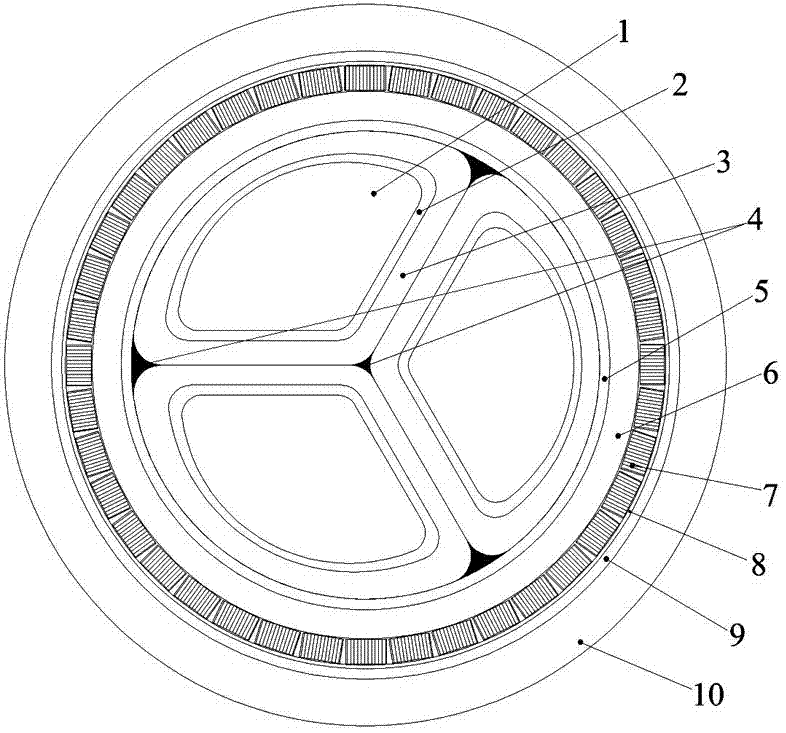

[0042] see figure 1 As shown, the present invention includes a cable core, and the periphery of the cable core is coated with a cable core water-blocking layer 5, a protective layer 6, an armor layer 7, a graphene-asphalt layer 8, and a water-blocking isolation layer from the inside to the outside in sequence (Fig. Not shown in), flame retardant layer 9 and sheath layer 10.

[0043]Wherein, the cable core is mainly composed of three strands of insulated conductors and a filling compound 4 . Each insulated conductor is mainly composed of a conductor 1 and an insulating layer 3 coated outside the conductor 1. The insulating layer 3 is an extruded cross-linked polyethylene insulating material structure; the conductor 1 of the insulated conductor is a solid single aluminum Alloy conductor structure, its cross-section is fan-shaped with a circular angle of about 120°, that is, it is extruded from an aluminum alloy rod, and there is no other assembly structure on the cross-section;...

Embodiment 2

[0064] The other content of this embodiment is the same as that of Embodiment 1, except that the conductor section of the insulated conductor is a tile-shaped structure, arched radially outwards, and is in the shape of an arc segment, and the angle between the center of the arc segment-shaped tile-shaped conductor is about is 120°.

Embodiment 3

[0066] The other content of this embodiment is the same as that of Embodiment 1, except that the conductor cross section of the insulated conductor is a circular structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com