Shielding box

A technology of shielding box and shielding layer, applied in the fields of magnetic field/electric field shielding, electrical components, metal containers, etc., can solve the problems of ineffective sealing effect, unenvironmental protection of metal plate welding process, and unenvironmental protection of sheet metal welding process. Manufacturing and labor costs, to meet standardized modularization and generalization, to ensure the effect of structural strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to illustrate the technical solution of the present invention more clearly, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Obviously, the following descriptions are only some embodiments of the present invention. In other words, other embodiments can also be obtained according to these embodiments without paying creative efforts.

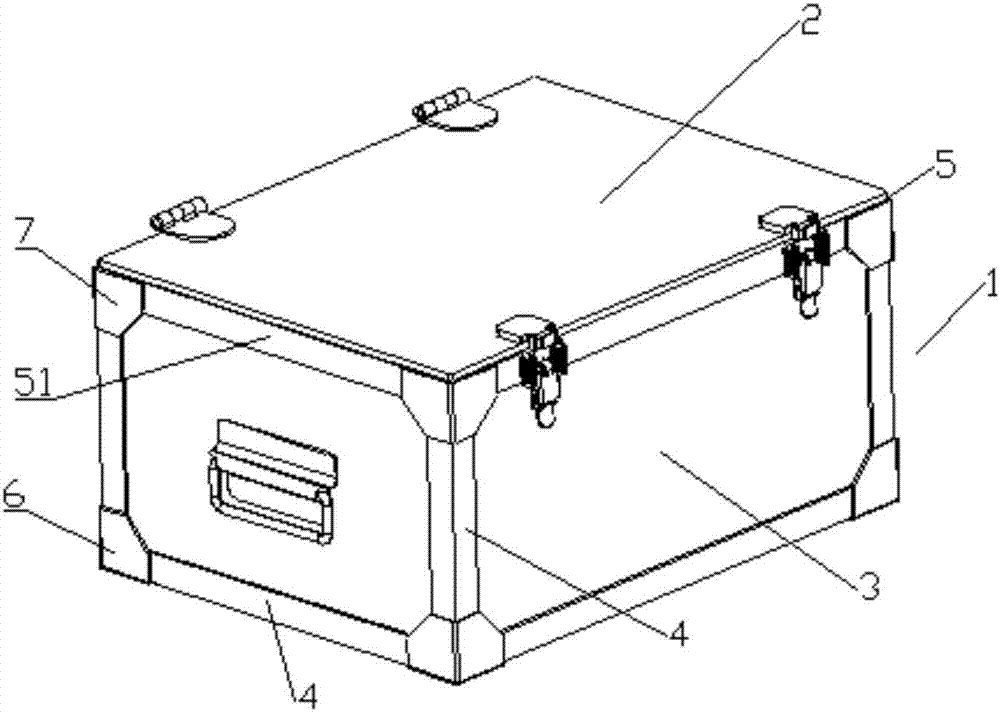

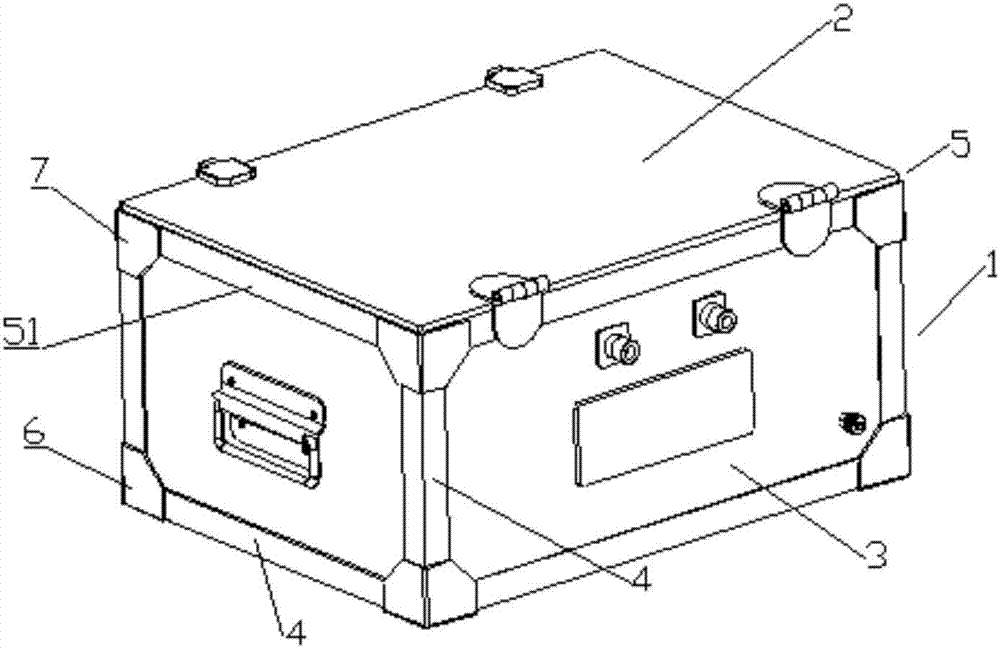

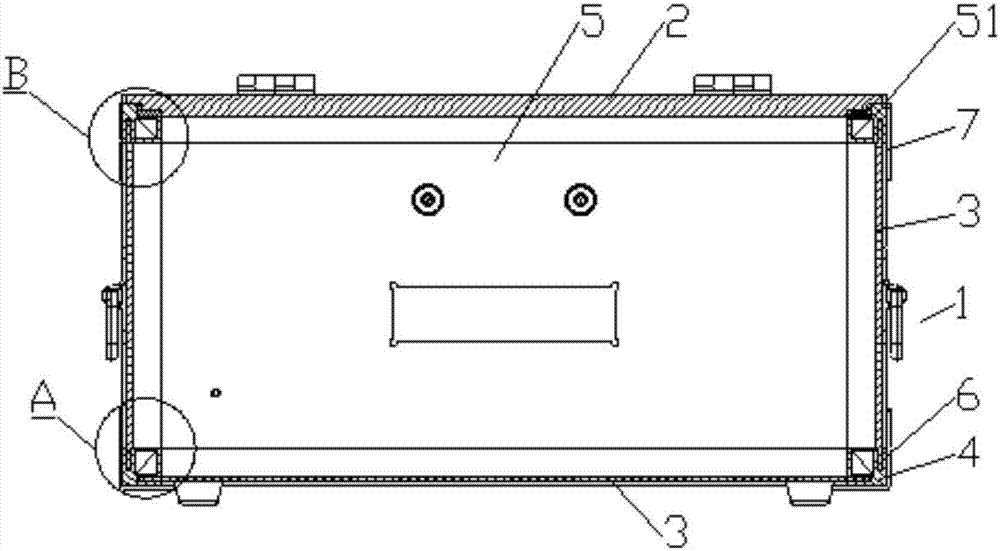

[0072] refer to Figure 1 to Figure 19 , a shielding box, including a box body 1 and a cover body 2, the main part of the box body 1 is spliced by a plurality of panels 3 and a plurality of profiles, and the box body 1 has a first opening 5; the profiles are provided with The inlay groove 11 matched with the edge of the surrounding board 3, the surrounding board 3 is assembled to the profile with the edge inserted into the inlaid groove 11, and the adjacent surrounding boards 3 are assembled to the same profile. Specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com