Banana-peel dietary fibers, low-sugar yoghurt and preparation method of low-sugar yoghurt

A technology of dietary fiber and banana peel, applied in the direction of bacteria, milk preparations, dairy products, etc. used in food preparation, can solve the problems of discarding and waste of resources, and achieve the effect of strong operability and advanced and reasonable production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

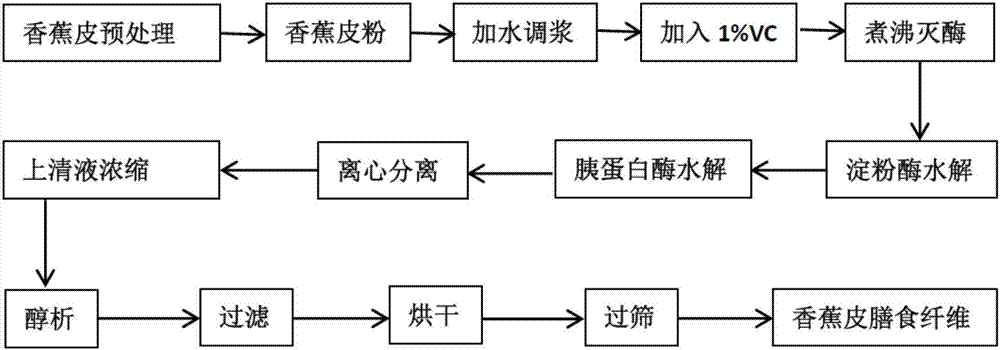

[0049] Banana peel dietary fiber is made by the method that comprises the following steps in the present embodiment (preparation flow process is as follows figure 1 shown):

[0050] 1) Take fresh and healthy banana peels, wash, dry, and pulverize them to obtain banana peel powder, mix the banana peel powder with water at a mass ratio of 1:20, and obtain a slurry;

[0051] 2) Mix the powder slurry with 1% vitamin C of banana peel powder raw material mass, boil for 2 minutes to inactivate the enzyme; add 1mol / L NaOH solution to adjust the pH of the system to 6, then add 6g of amylase per kg of banana peel powder raw material to enzymatically hydrolyze at 80°C 60 minutes; then add 1mol / L NaOH solution to adjust the pH to 7, then add trypsin 3g per kg of banana peel powder raw material and enzymolyze at 55°C for 100min to obtain the enzymolysis solution;

[0052] 3) After centrifuging the enzymolysis solution, take the supernatant, put the supernatant in a rotary evaporator and con...

Embodiment 2

[0059] Banana peel dietary fiber is made by the method comprising the following steps in the present embodiment:

[0060] 1) Take fresh and healthy banana peels, wash, dry, and pulverize them to obtain banana peel powder, mix the banana peel powder with water at a mass ratio of 1:30, and obtain a slurry;

[0061] 2) Mix the powder slurry with 1% vitamin C of banana peel powder raw material mass, boil for 2 minutes to inactivate the enzyme; add 1mol / L NaOH solution to adjust the pH of the system to 5, then add 6g of amylase per kg of banana peel powder raw material to enzymatically hydrolyze at 85°C 60 minutes; then add 1mol / L NaOH solution to adjust the pH to 7, then add trypsin 3g per kg of banana peel powder raw material and enzymolyze at 55°C for 100min to obtain the enzymolysis solution;

[0062] 3) After centrifuging the enzymatic solution, take the supernatant, put the supernatant in a rotary evaporator and concentrate it to 1 / 3 of the original volume, the parameters of ...

Embodiment 3

[0069] Banana peel dietary fiber is made by the method comprising the following steps in the present embodiment:

[0070] 1) Take fresh and healthy banana peels, wash, dry, and pulverize them to obtain banana peel powder, mix the banana peel powder with water at a mass ratio of 1:50, and obtain a slurry;

[0071] 2) Mix the powder slurry with 1% vitamin C of banana peel powder raw material mass, boil for 2 minutes to inactivate the enzyme; add 1mol / L NaOH to adjust the pH of the system to 6, then add 8g of amylase per kg of banana peel powder raw material and enzymolyze at 80°C for 60 minutes ; Then add 1mol / L NaOH to adjust the pH to 7, then add trypsin 6g per kg of banana peel powder raw material and enzymolyze at 55°C for 100min to obtain an enzymolysis solution;

[0072] 3) After centrifuging the enzymolysis solution, take the supernatant, put the supernatant in a rotary evaporator and concentrate it to 1 / 3 of the original volume, the parameters of the rotary evaporation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com