Nitrogen-containing porous carbon material, and capacitor and manufacturing method thereof

A technology of porous carbon and manufacturing method, which is applied in the direction of hybrid capacitor electrodes, carbon preparation/purification, ceramic products, etc., can solve the problem that the properties of porous carbon materials are difficult to further improve, and achieve reduction in use and cost, and increase storage capacity. performance and reduce the use of area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Relating to the detailed description and technical contents of the present invention, it is now described as follows with regard to the accompanying drawings:

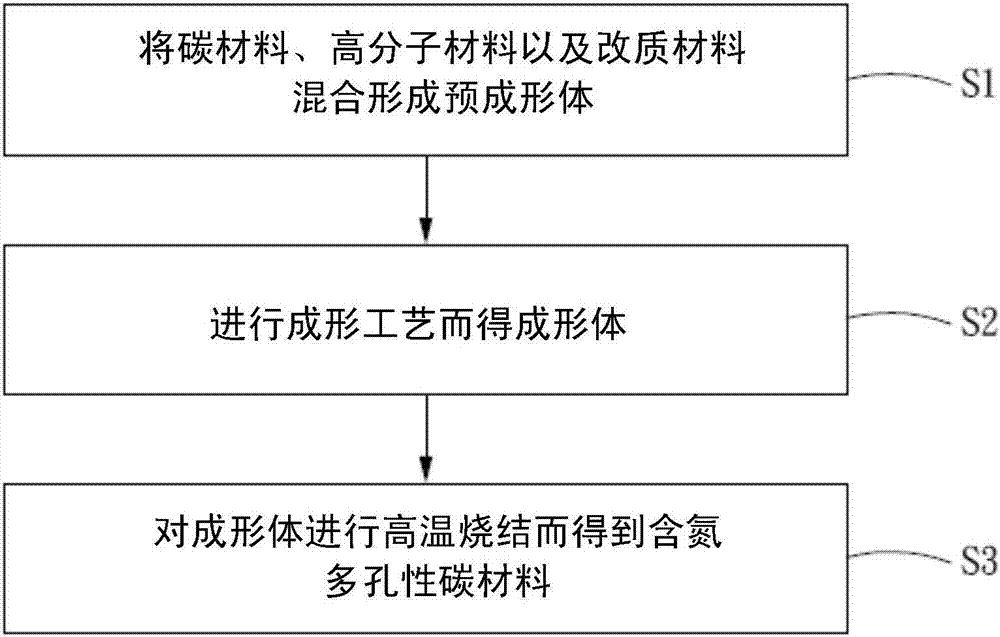

[0037] see figure 1 , the present invention is a nitrogen-containing porous carbon material and its capacitor and manufacturing method, the manufacturing method comprising the following steps:

[0038] S1: Mix a carbon material, a polymer material and a modified material to form a preformed body. The carbon material can be carbon black, carbon fiber, carbon nanotube, vapor phase grown carbon fiber, activated carbon, graphite, graphene, hollow carbon, soft carbon, hard carbon or a combination thereof, the polymer material can be phenolic resin (Phenol formaldehyde resin), epoxy resin (Epoxy), polyacrylonitrile (Polyacrylonitrile, referred to as PAN), furan resin (Furan resin), poly Polyvinylalcohol (PVA for short), Polyvinyl chloride (PVC for short), Cellulose (Cellulose), Polyvinylidene fluoride (PVDF for short...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com