Sulfonate detergent, preparation method and applications thereof

A technology of detergent and sulfonate, applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of limited anti-oxidation effect, achieve the effect of improving anti-oxidation performance, improving the problem of phase separation, and improving the efficiency of post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

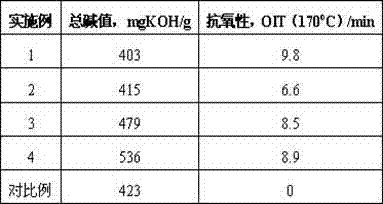

Examples

preparation example Construction

[0022] The embodiment of the present invention discloses a preparation method of a sulfonate detergent, comprising:

[0023] a) Neutralize reaction by mixing alkylsulfonic acid and / or alkylsulfonate, basic compound and solid acid with diluent and / or accelerator which may or may not be added;

[0024] b) adding a basic compound, and introducing carbon dioxide for carbonation;

[0025] c) Separation to obtain the target product.

[0026] In the above-mentioned preparation method, the preparation method of the alkylsulfonic acid and / or alkylsulfonate comprises: aromatic compound and C 8 -C 45 Alkylation of olefins, followed by reaction with a sulfonating agent to give alkylsulfonic acids and / or alkylsulfonates.

[0027] For example, the aromatic compound includes any one or a combination of two or more of benzene, toluene, xylene, naphthalene, and anthracene.

[0028] And / or, the olefin comprises C 14 -C 30 Any one or a combination of two or more of the olefins, preferably ...

Embodiment 1

[0061] Add 30g of alkylsulfonic acid, 7mL of methanol, 85mL of toluene, 2.3g of calcium oxide, 4.6mL of water and 10g of acid clay activated by C14 alkyl salicylic acid into the reaction flask equipped with a stirrer, and react at no more than 75°C After 1h, add 25g of calcium hydroxide, mix for 20min, pass CO 2 (The rate is 100mL / min~400mL / min) over 2 hours, add 32g of base oil, heat up to 120°C to distill methanol and generated water, etc., then centrifugally filter to obtain a clear solution, distill toluene under reduced pressure at 150°C, and finally get Calcium Sulfonate Detergent.

Embodiment 2

[0063] Add 30g of alkylsulfonic acid, 9.7g of methanol, 92.8g of toluene, 4.5g of calcium hydroxide and 15g of acid clay activated by C12 alkylphenol into the reaction flask equipped with a stirrer, and react at no more than 75°C for 1h, Add 20g of calcium hydroxide, mix for 20min, pass CO 2 (The rate is 100mL / min~400mL / min) over 2 hours, add 32g of base oil, heat up to 120°C to distill methanol and generated water, etc., then centrifugally filter to obtain a clear solution, and distill toluene under reduced pressure at 150°C. Finally, a calcium sulfonate detergent is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com