Thickened composite film based on diamond-like carbon thin film and coating method of thickened composite film

A technology of diamond film and composite film, which is applied in the direction of superimposed layer plating, sputtering plating, ion implantation plating, etc., can solve the impact of coating service life and efficiency, the increase of internal stress of Layer and substrate bonding force and other issues, to achieve the effect of good microstructure, convenient control, and increase the range of nano-hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

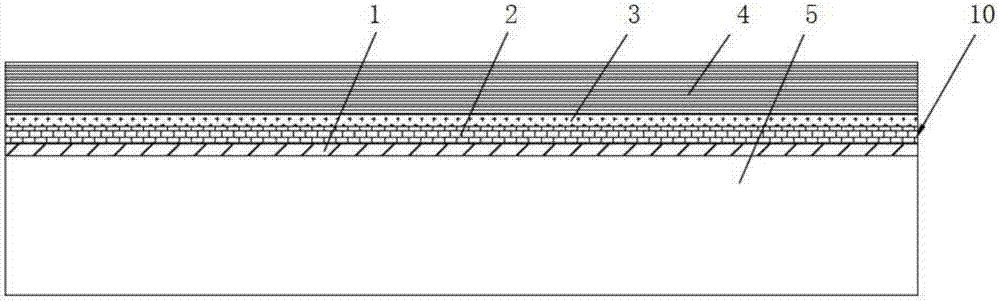

[0035] The present invention discloses a thickened composite film based on a diamond-like film, at least applied to a piston ring, as attached figure 1 As shown, it includes a transition layer 10 including at least a metal underlayer 1 and a codeposited layer 2 and a diamond-like carbon layer 4 sequentially formed from the surface of the substrate 5 outward.

[0036] Wherein, the base material 5 is preferably made of various materials used to manufacture piston rings, such as 13Cr or stainless steel or cast iron.

[0037] Described metal bottom laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com