Gas Sensing Components, Gas Sensing Devices and Systems

A gas sensor and gas sensor technology, applied in the field of gas sensor, can solve the problem of low yield rate and achieve excellent anti-deactivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of the gas-sensitive material according to some embodiments of the present invention includes: mixing one or more oxide nanopowders with an optional catalyst; making the mixture granulated and then compression-molded, and the molding pressure can be, for example, 1-20MPa , especially 5-15MPa, to obtain a green body; sintering the green body to obtain a sintered body, the temperature, time and atmosphere of the sintering process are selected so that the sintered body meets the requirements of the gas-sensitive material of the aforementioned scheme. In some embodiments, a gas sensor or a gas-sensitive electronic device can be manufactured using the sintered body, especially including forming electrodes on the sintered body, and the electrodes can be formed by conventional electrode materials such as platinum, gold or silver through conventional processes.

[0059] While not wishing to be bound by any theory, the oxide structures and associated fabric...

Embodiment 1

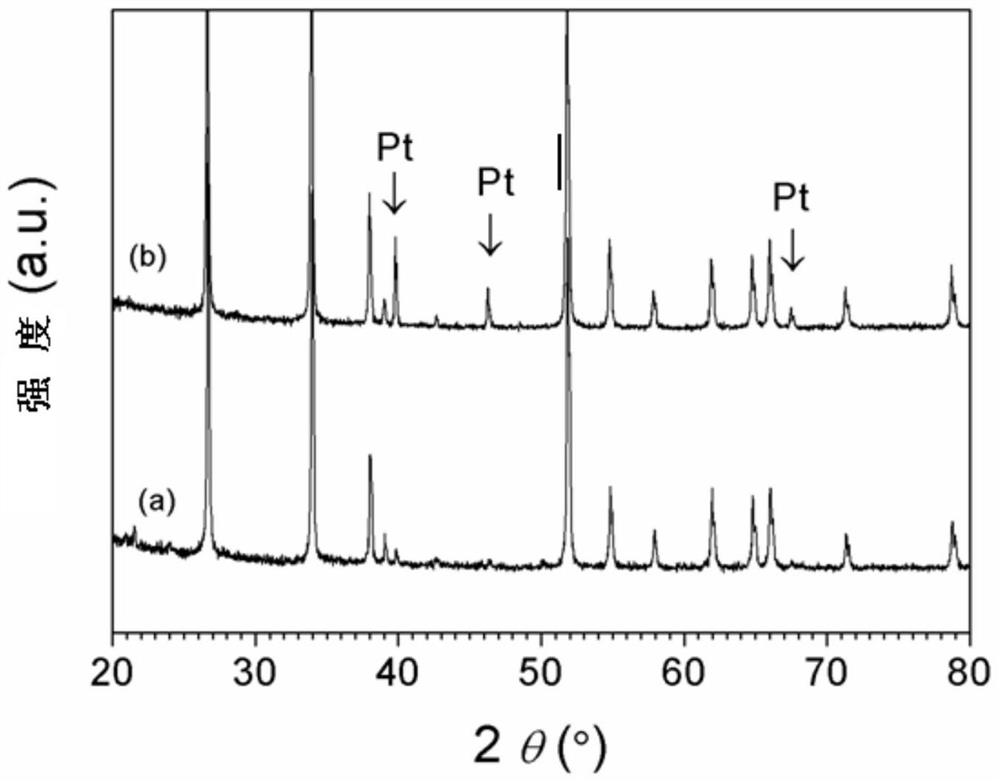

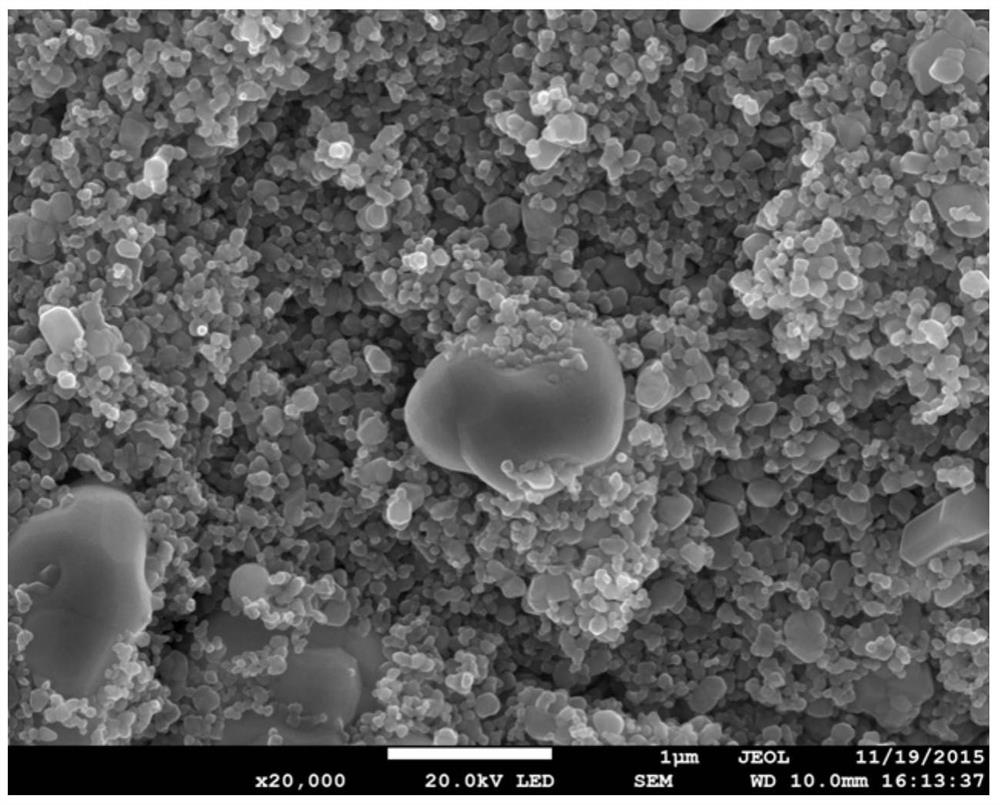

[0063] Example 1: SnO with a (average) particle size of 70 nm with unimodal distribution characteristics 2 Powder and Pt powder with a particle size of about 850 nanometers were mixed at a mass ratio of 95:5, deionized water was added to make a suspension, and magnetic stirring was performed for 4 hours. Dried after centrifugation, pressed under 10MPa pressure, 12mm in diameter, 2mm in thickness, and sintered in air at 900°C for 2 hours. A pair of gold electrodes were formed on the surface of the sample by magnetron sputtering with a distance of 3 mm between the electrodes. In this way, a hydrogen sensor capable of hydrogen gas sensing test is obtained.

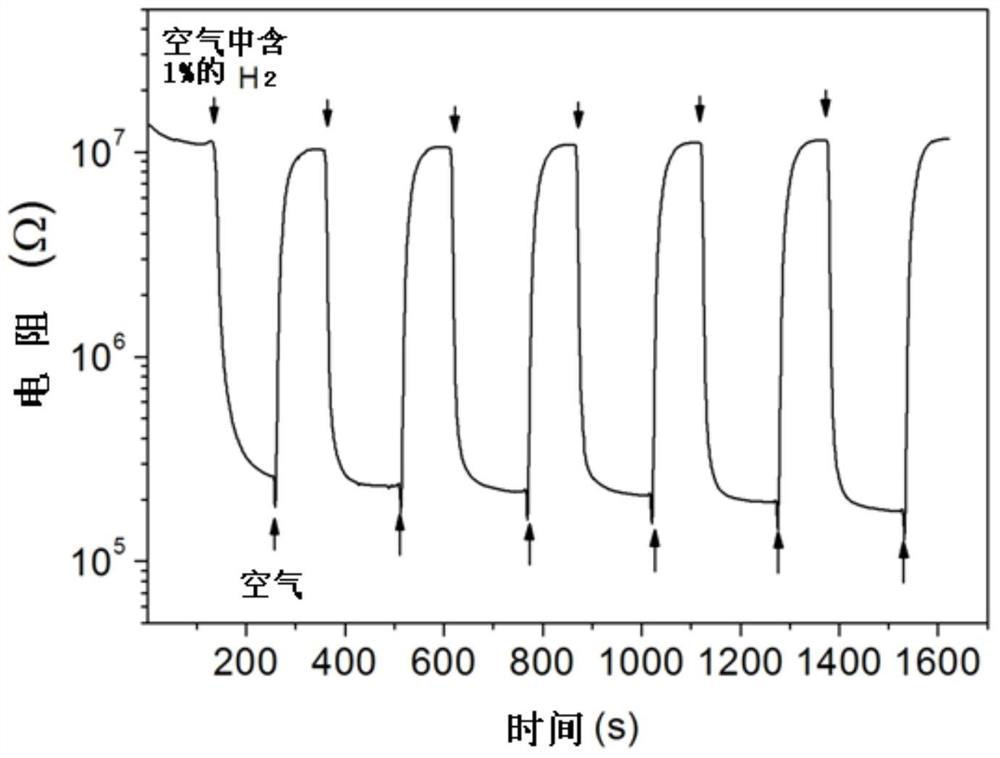

[0064] The hydrogen gas sensitivity test includes placing the sample in a closed chamber (approximately 350 milliliters volume) with an inlet and an outlet. At the detection temperature, after passing a detection gas containing hydrogen, apply A certain voltage, start to measure the current at each moment in the circuit, so...

Embodiment 2

[0068] Embodiment 2: In addition to using SnO with a particle size of 70 nanometers 2 powder, 50nm Al 2 o 3 Powder and Pt powder were mixed at a mass ratio of 92:3:5, and a hydrogen sensor was prepared in the same manner as in Example 1 for testing. The test result shows that it possesses similar hydrogen sensitivity properties as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com