Chlorine-resistant composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and nanofiltration membrane technology, which is applied in the field of membrane separation, can solve problems such as difficulty in obtaining chlorine resistance, and achieve the effects of widening the scope of use, high chlorine resistance, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

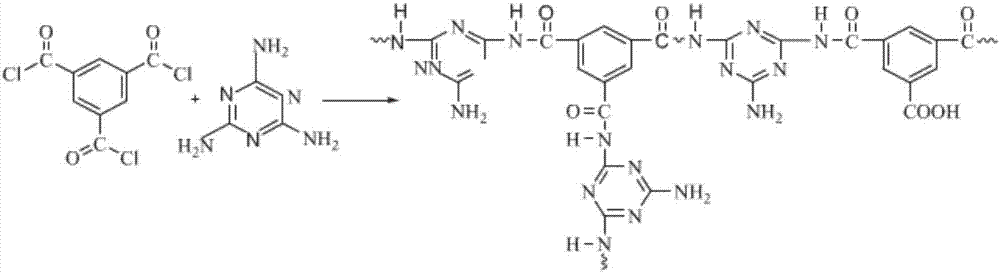

Image

Examples

Embodiment 1

[0033] (1) Preparation of separation membrane:

[0034] Using polyethersulfone as the support layer membrane material and N,N‐dimethylacetamide (DMAc) as the solvent, the polyethersulfone ultrafiltration membrane was prepared by phase inversion method. Using it as the base membrane, the composite nanofiltration membrane functional layer is prepared on it by interfacial polymerization method. The details are as follows: 2 wt% of melamine is used as the monomer of the water phase, 0.5% of trimesoyl chloride is used as the monomer of the organic phase, n-hexane is used as the solvent, and the film is prepared by interfacial polymerization. The formed primary film was dried in an oven at a temperature of 60° C. for 5 minutes.

[0035]

[0036] (2) Application:

[0037] The treatment solution is 1 g / L sodium sulfate solution containing 0.2% NaClO. When the external pressure is 0.4MPa, the rejection rate of the separation membrane to the inorganic salt sodium sulfate is 88%, a...

Embodiment 2

[0039] (1) Preparation of separation membrane:

[0040]Using polyethersulfone as the support layer membrane material and N,N‐dimethylacetamide (DMAc) as the solvent, the polyethersulfone ultrafiltration membrane was prepared by phase inversion method. Using it as the base membrane, the composite nanofiltration membrane functional layer is prepared on it by interfacial polymerization method. The details are as follows: 2 wt% of melamine and 0.5% of piperazine are used as water phase monomers, 0.5% of trimesoyl chloride is used as organic phase monomers, n-hexane is used as solvent, and the film is prepared by interfacial polymerization. The formed primary film was dried in an oven at a temperature of 60° C. for 5 minutes.

[0041] (2) Application

[0042] The treatment solution is 1 g / L sodium sulfate solution containing 0.2% NaClO. When the external pressure is 0.4MPa, the rejection rate of the separation membrane to inorganic salt ions is 95%, and the water flux can reach ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com