A method for rapidly synthesizing zif-61 materials

A ZIF-61 and mixed solution technology, which is applied in the field of rapid synthesis of ZIF-61 materials, can solve the problems of application limitations and small surface area, and achieve the effects of simple operation, mild conditions and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 2.00g Zn(NO 3 ) 2 ·6H 2 O. Dissolve 2.75g imidazole and 1.11g 2-methylimidazole in 20ml methanol, stir; add 0.173g N,N,N,N-tetramethylhexamethylenediamine to the mixed solution obtained above, stir the obtained mixture for 1min The product was filtered with suction; the filtered product was dried in a vacuum oven at 150°C for 12 hours to obtain a ZIF-61 material, labeled as sample A1. Through calculation, the productive rate of product is: 95%, and productive rate is higher.

Embodiment 2

[0032] 2.00g Zn(NO 3 ) 2 ·6H 2 O. Dissolve 2.75g imidazole and 1.11g 2-methylimidazole in 20ml methanol, stir; add 0.35g N,N,N,N-tetramethylhexamethylenediamine to the mixed solution obtained above, stir the obtained mixture for 1min The product was filtered with suction; the filtered product was dried in a vacuum oven at 150° C. for 12 hours to obtain a ZIF-61 material, labeled as sample A2. Through calculation, the productive rate of product is: 96%, and productive rate is higher.

Embodiment 3

[0034] 2.00g Zn(NO 3 ) 2 ·6H 2 O. Dissolve 2.75g imidazole and 1.11g 2-methylimidazole in 20ml methanol and stir; add 0.51g N,N,N,N-tetramethylhexamethylenediamine to the mixed solution obtained above, stir the obtained mixture for 1min The product was filtered with suction; the filtered product was dried in a vacuum oven at 150° C. for 12 hours to obtain a ZIF-61 material, labeled as sample A3. After calculation, the yield of the product is: 96.8%, which is relatively high.

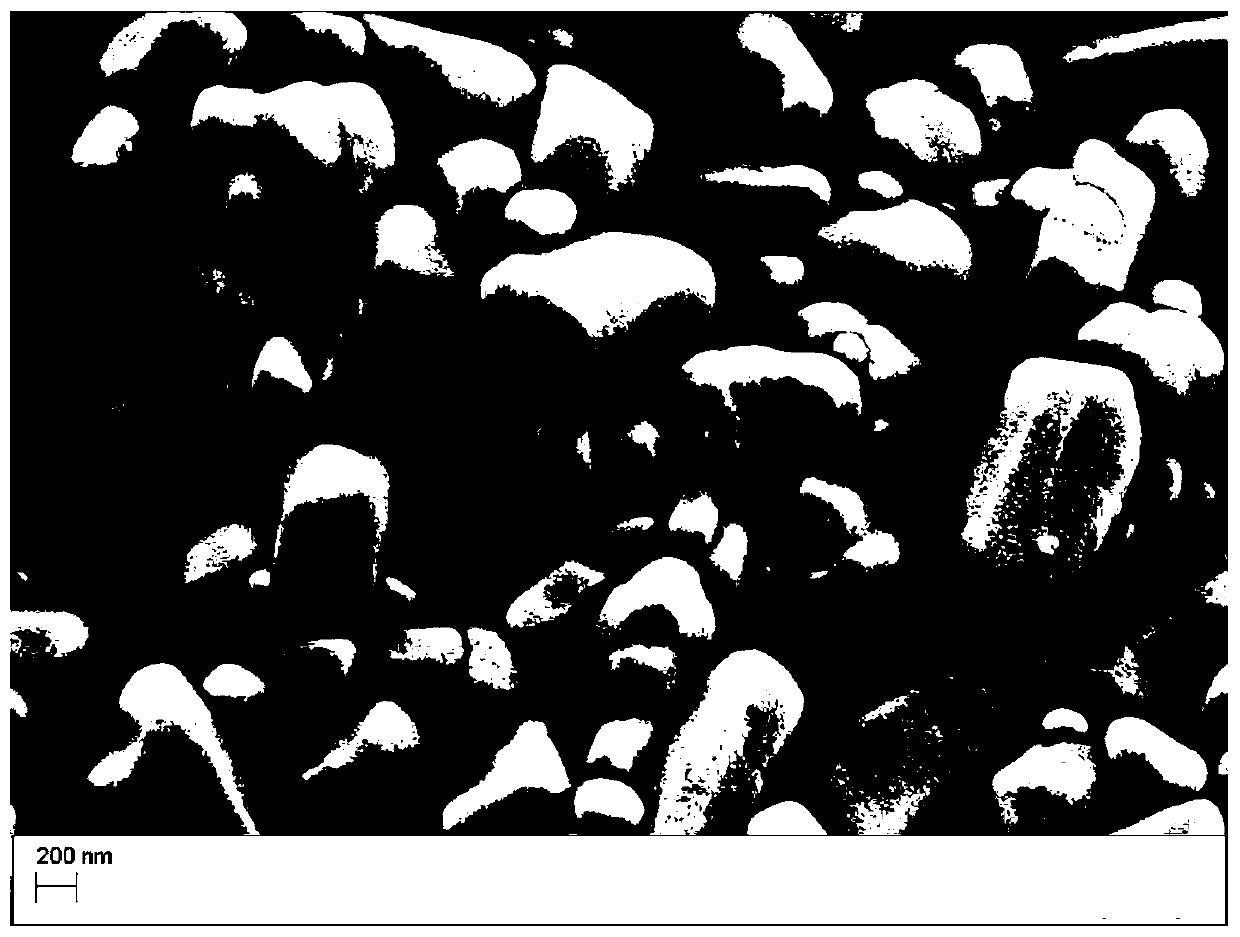

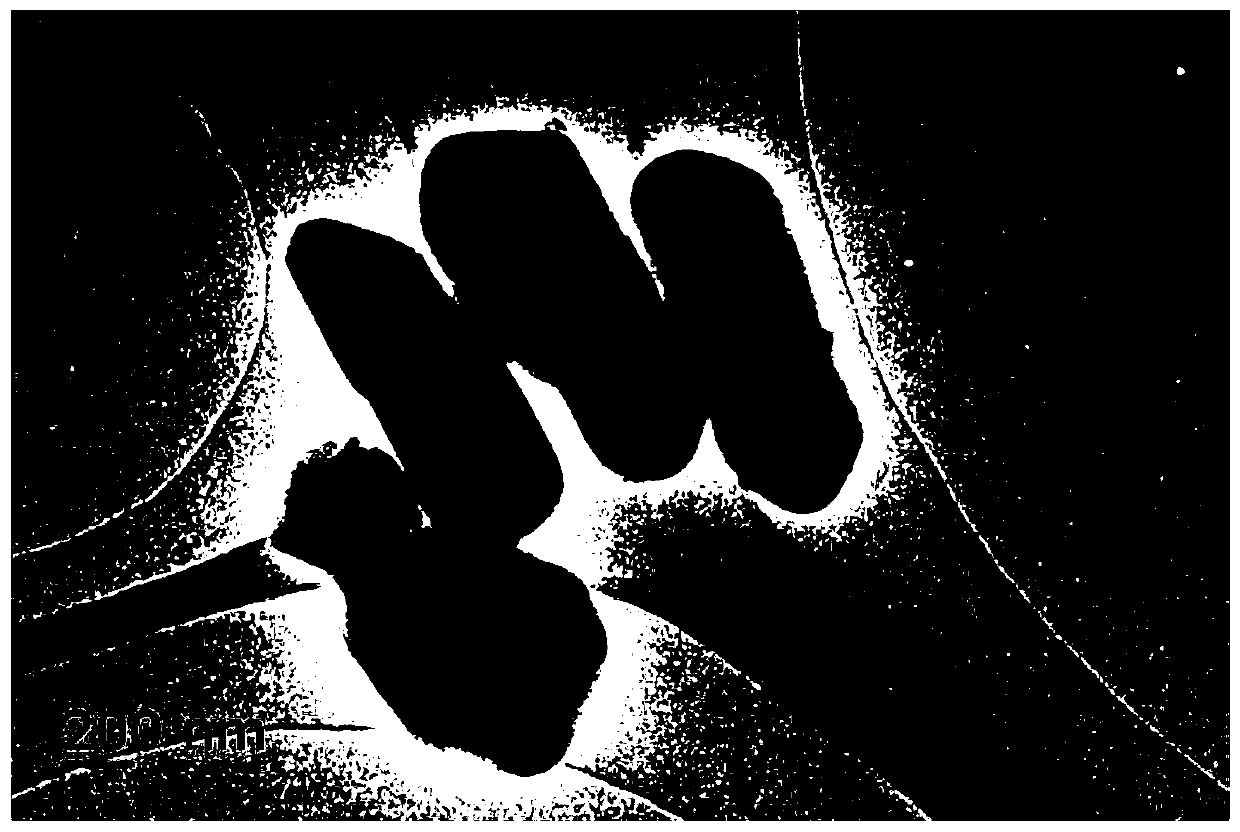

[0035] The ZIF-61 material rapidly prepared in Example 1 and Example 3 was analyzed as a representative. The analysis results of the ZIF-61 material prepared in other examples are basically the same as those in Example 1 and Example 3, and are not provided one by one.

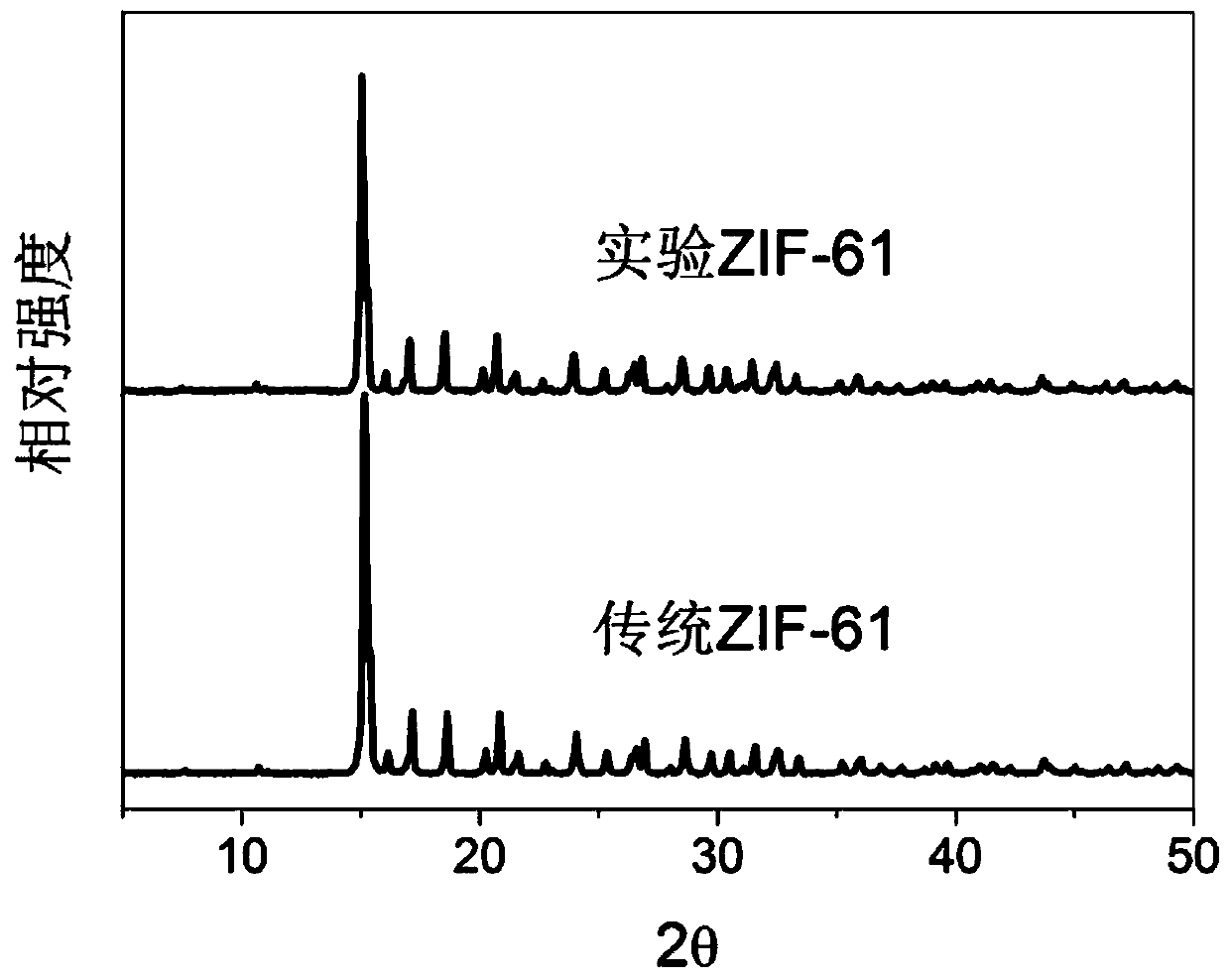

[0036] (1) Crystal structure properties of the rapidly synthesized ZIF-61 material

[0037] The crystal structure of Example A of the present invention was characterized by using a D8-ADVANCE model X-ray diffractometer produced by Ger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com