Nonmagnetic steel product and manufacturing method thereof

A manufacturing method, the technology of non-magnetic steel, applied in the field of powder metallurgy, can solve the problems of unsatisfactory high cost performance in the market, unsatisfactory mechanical properties of non-magnetic steel, high process cost, etc., and achieve low cost, high product precision, and expansion The effect of the range of industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

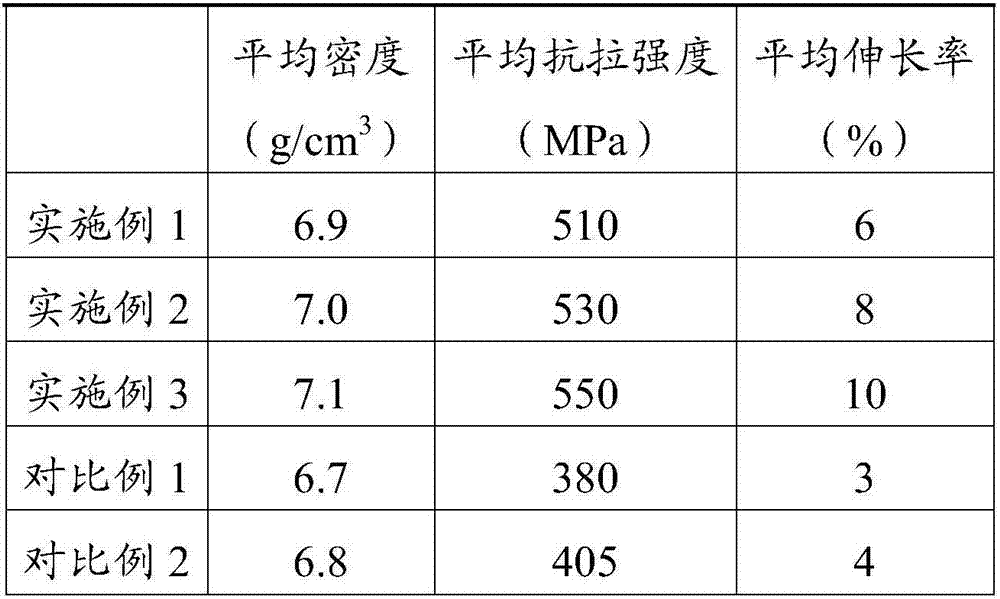

Examples

Embodiment 1

[0031] A kind of manufacturing method of non-magnetic steel product (balance weight) of present embodiment, comprises the steps:

[0032] a) First, take the Fe-Mn pre-alloy powder, and add 4% activator and 0.3% graphite according to the weight percentage of the Fe-Mn pre-alloy powder, then add the Fe-Mn pre-alloy powder, activator, The paraffin-based wax powder binding agent of 1.2% of the total weight of graphite is evenly stirred with a powder mixer for subsequent use.

[0033] Wherein, the activator is FeB master alloy powder, wherein the weight percentage of the B powder is 20%;

[0034] The Fe-Mn pre-alloyed powder includes the following components by weight percentage: Mn 15%, C 1.2%, Si 0.7, S≤0.05%, P≤0.09%, Pb≤0.2%, Sn≤0.2%, and the balance is Fe.

[0035] b) Send the mixed mixed powder to an ordinary mechanical press for compression molding to make a green body of the balance weight, and the density is controlled at 5.8g / cm 3 .

[0036] c) Sintering the pressed gr...

Embodiment 2

[0040] A kind of manufacturing method of non-magnetic steel product (balance weight) of present embodiment, comprises the steps:

[0041] a) First, take the Fe-Mn pre-alloy powder, and add 3% activator and 0.5% graphite according to the weight percentage of the Fe-Mn pre-alloy powder, then add the Fe-Mn pre-alloy powder, activator, The paraffin-based wax powder binder of 0.9% of the total weight of graphite is stirred evenly with a powder mixer for subsequent use.

[0042] Wherein, the activator is FeB master alloy powder, wherein the weight percentage of the B powder is 15%;

[0043] The Fe-Mn pre-alloyed powder includes the following components by weight percentage: Mn 17%, C 0.9%, Si 1.0, S≤0.05%, P≤0.09%, Pb≤0.2%, Sn≤0.2%, and the balance is Fe.

[0044] b) Send the mixed mixed powder to an ordinary mechanical press for compression molding to make a green body of the balance weight, and the density is controlled at 6.0g / cm 3 .

[0045] c) Sintering the pressed green bod...

Embodiment 3

[0049]A kind of manufacturing method of non-magnetic steel product (balance weight) of present embodiment, comprises the steps:

[0050] a) First, take the Fe-Mn pre-alloy powder, and add 2% activator and 0.6% graphite according to the weight percentage of the Fe-Mn pre-alloy powder, then add the Fe-Mn pre-alloy powder, activator, The paraffin-based wax powder binder of 0.5% of the total weight of graphite is stirred evenly with a powder mixer for subsequent use.

[0051] Wherein, the activator includes FeB master alloy powder, wherein the weight percentage of the B powder is 25%;

[0052] The Fe-Mn pre-alloyed powder includes the following components by weight percentage: Mn 19%, C 0.6%, Si 0.8, S≤0.05%, P≤0.09%, Pb≤0.2%, Sn≤0.2%, and the balance is Fe.

[0053] b) Send the mixed mixed powder to an ordinary mechanical press for compression molding to make a green body of the balance weight, and the density is controlled at 6.2g / cm 3 .

[0054] c) Sintering the pressed gree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com