Synthetic method and application of polyacrylic acid-packaged nano-tricobalt tetraoxide

A technology of tricobalt tetroxide and polyacrylic acid, which is applied in chemical instruments and methods, water treatment of special compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of difficult realization of practical value, unfavorable large-scale promotion, and low catalytic activity etc. to achieve the effects of low power consumption, fast degradation rate, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

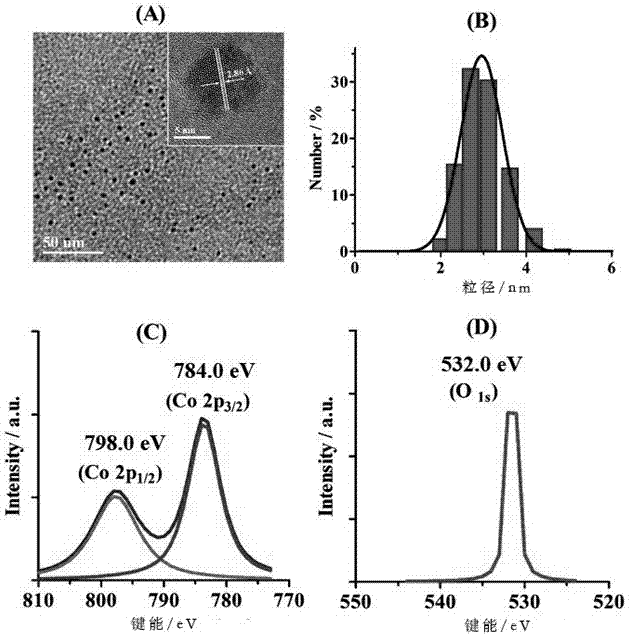

Embodiment 1

[0036] will contain 1 M CoCl 2 •6H 2 A solution of O (2.17 g in 5.0 mL of water) was mixed with 10 mL of PAA solution (0.05 M). With continuous stirring, the mixture was added to 30 mL of ammonia solution. The mixture was stirred continuously for another 24 hours, during which time the color of the solution changed from purple to dark brown, which indicated the formation of PAA-Co 3 o 4 . The product was then centrifuged at 4000 rpm for 30 minutes to remove large agglomerates and debris, and the supernatant was purified and concentrated using a 30K ultrafiltration centrifuge tube. Finally, the resulting solution was freeze-dried to obtain a brown solid powder.

Embodiment 2

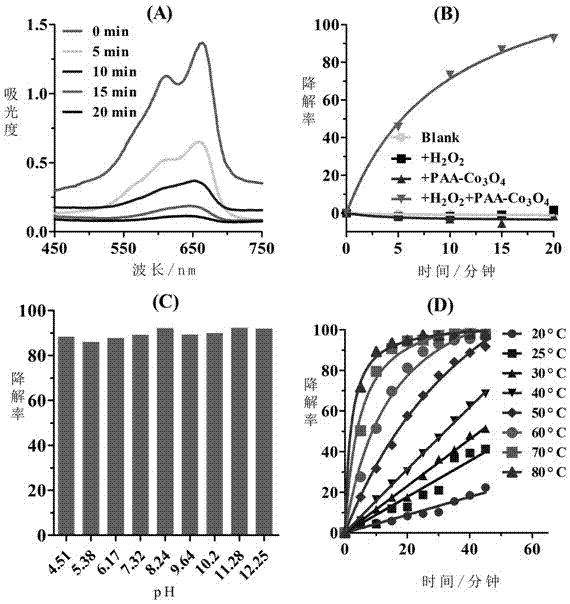

[0038] PAA-Co 3 o 4 (1 mg / mL) and MB solution (30 mg / L), then add H 2 o 2 (1 M), the temperature is controlled at 60 degrees Celsius, and the absorbance change of the solution is recorded with a UV-visible spectrophotometer, such as figure 2 (A) and figure 2 (B) shown. As the reaction proceeded, the dye had been substantially completely degraded within 15 minutes.

Embodiment 3

[0040] PAA-Co 3 o 4 (1 mg / mL) and MB solution (30 mg / L), then adjust the pH of the solution to 4.51, 5.38, 6.17, 7.32, 8.24, 9.64, 10.2, 11.28, 12.25 with sodium hydroxide and hydrochloric acid, and control the temperature is 60 degrees Celsius, and finally add H to these 9 solutions 2 o 2 (1 M), after 20 minutes the dye degradation rate was calculated as figure 2 (C) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com