A material of a cold shrink sealed pipe and a preparing method thereof

A technology of sealed tubes and solid materials, applied in the field of cold-shrinkable sealed tube materials and their preparation, can solve problems such as poor corrosion resistance and fire resistance, unsatisfactory mechanical properties, and heavy quality of cold-shrinkable sealed tubes, etc., to achieve strong corrosion resistance, Save investment in production equipment, good high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A cold-shrink sealing tubing material, comprising the following components:

[0031] The xenotime material of 190 parts by weight, the solid material of 1800 parts by weight, the epoxy resin 501A of 1100 parts by weight, the epoxy resin 501B of 250 parts by weight, the calcium carbonate powder of 60 parts by weight resin foaming agent, 545 parts by weight, 180 parts by weight of 80FA soft resin, 150 parts by weight of fluororesin, 5 parts by volume of accelerator cobalt naphthenate, and 2 parts by volume of curing agent methyl ethyl ketone peroxide; wherein the corresponding relationship between parts by weight and parts by volume is g / mL.

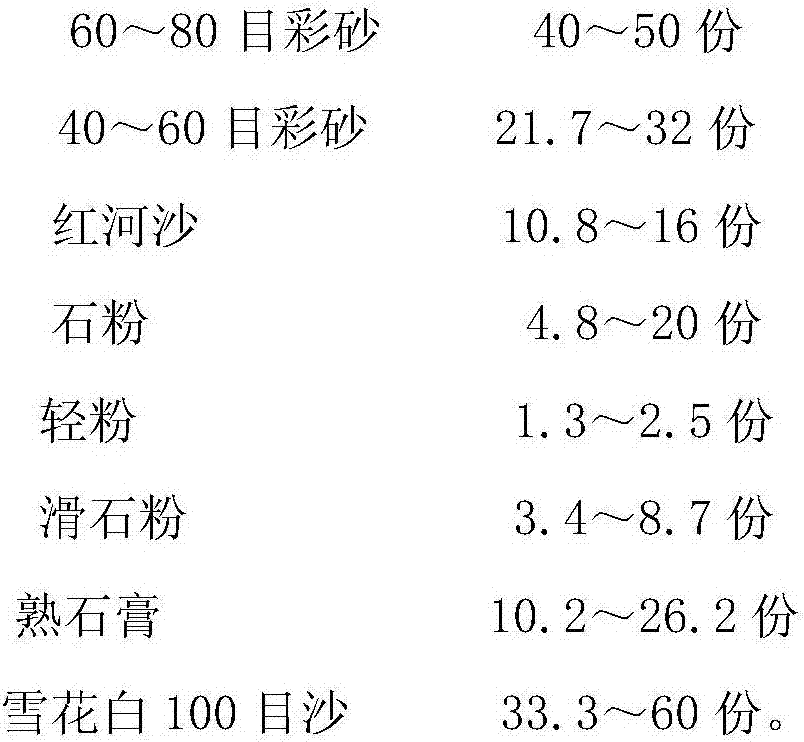

[0032] Described solid material comprises each component of following parts by weight:

[0033]

[0034] The preparation method of the cold-shrinkable sealing pipe material comprises the following steps:

[0035] (1) Weigh 190-210 parts by weight of xenotime-based materials and 0.5-1 parts by volume of accelerator cobalt naphthe...

Embodiment 2

[0044] A cold-shrink sealing tubing material, comprising the following components:

[0045] The xenotime material of 210 parts by weight, the solid material of 1885 parts by weight, the epoxy resin 501A of 1300 parts by weight, the epoxy resin 501B of 270 parts by weight, the calcium carbonate powder of 70 parts by weight resin foaming agent, 595 parts by weight, 210 parts by weight of 80FA soft resin, 200 parts by weight of fluororesin, 8 parts by volume of accelerator cobalt naphthenate, and 6 parts by volume of curing agent methyl ethyl ketone peroxide; wherein the corresponding relationship between parts by weight and parts by volume is g / mL.

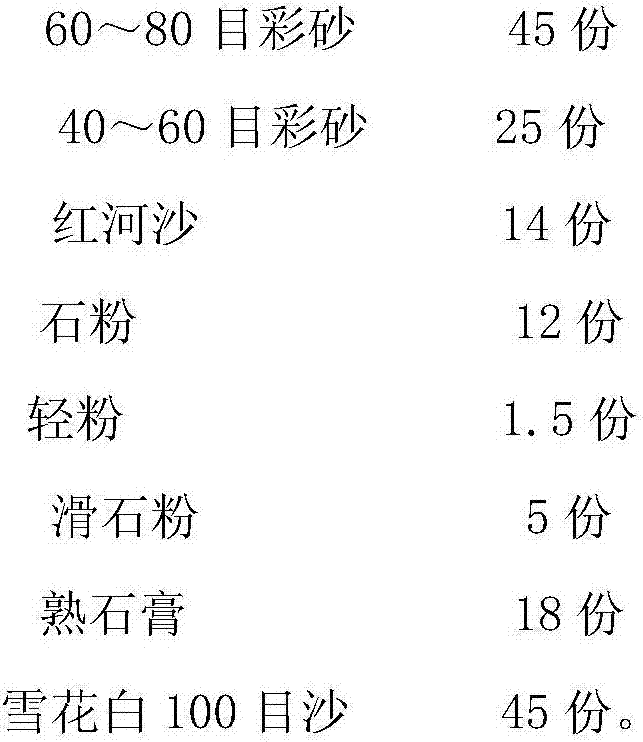

[0046] Described solid material comprises each component of following parts by weight:

[0047]

[0048] Its manufacturing process includes the following steps:

[0049](1) Weigh 190-210 parts by weight of xenotime-based materials and 0.5-1 parts by volume of accelerator cobalt naphthenate, stir well, then add 0.5-1 parts by vol...

Embodiment 3

[0058] 200 parts by weight of xenotime material, 1840 parts by weight of solid material, 1200 parts of epoxy resin 501A by weight, 260 parts of epoxy resin 501B, 65 parts by weight of resin blowing agent, calcium carbonate powder of 570 parts by weight, 235 parts by weight of 80FA soft resin, 175 parts by weight of fluororesin, 6.8 parts by volume of accelerator cobalt naphthenate, 2-6 parts by volume of curing agent methyl ethyl ketone peroxide; wherein the corresponding relationship between parts by weight and parts by volume is g / mL .

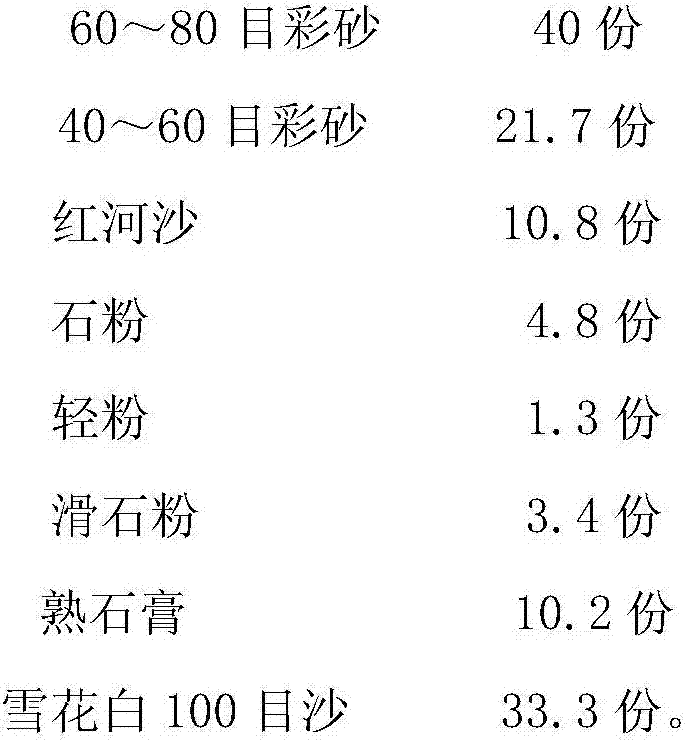

[0059] Described solid material comprises each component of following parts by weight:

[0060]

[0061] The preparation method of the cold-shrinkable sealing pipe material comprises the following steps:

[0062] (1) Weigh 190-210 parts by weight of xenotime-based materials and 0.5-1 parts by volume of accelerator cobalt naphthenate, stir well, then add 0.5-1 parts by volume of curing agent methyl ethyl ketone peroxide, mix After unifor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap