Orientated-textured Ti2AlC-Mg-based composite material and hot-extrusion preparation method thereof

A composite material and texturing technology, applied in the field of directional textured Ti2AlC-Mg based composite material and its hot extrusion preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

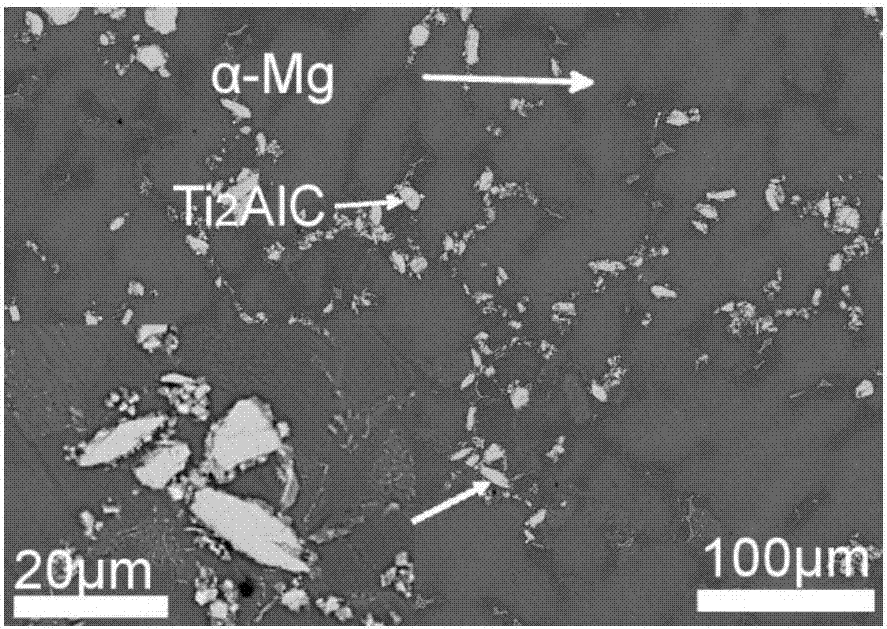

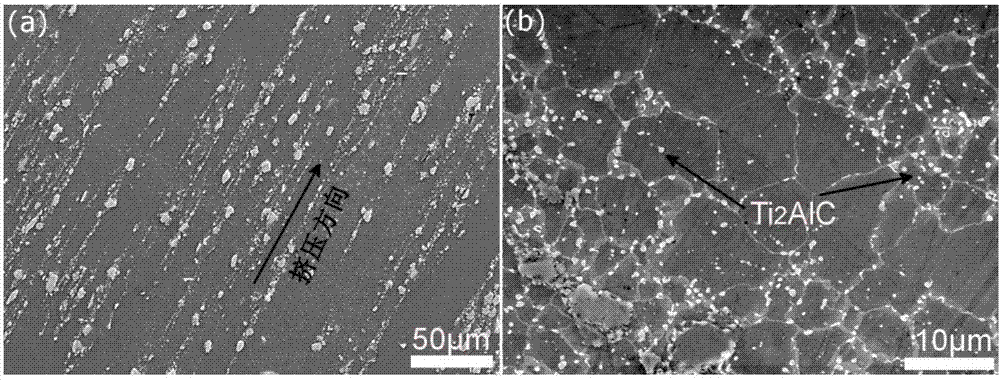

[0023] For 10vol% Ti 2 The AlC-AZ91D material was heat-treated at 400°C for 24 hours to make the Mg alloy uniformly solutionized. Directional textured Ti was prepared at 250-℃ with extrusion ratio of 12:1 and rate of 1 / s 2 AlC / Mg based composites results show that Ti 2 AlC grains do not appear cracked and detached, such as figure 2 shown. and figure 1 Ti in initial state composite 2 AlC is arranged at the α-Mg grain boundary compared to Ti 2 AlC particles are distributed along the extrusion direction. In addition, some submicron and nanometer Ti 2AlC grains are dispersed into Mg grains, which is beneficial to greatly improve the mechanical properties of the composites. ⊥Extrusion direction and / / extrusion direction, the compressive strength of the composite material is 500MPa and 450MPa respectively; the tensile strength of the composite material is 250MPa and 370MPa respectively.

Embodiment 2

[0025] For 15vol% Ti 2 The AlC-AZ91D material was heat-treated at 420°C for 36 hours to make the Mg alloy uniformly solutionized. Orientation-textured Ti 2 AlC-Mg based composites. High-energy CT scans and reconstructions were carried out before and after hot extrusion of composite materials, as shown in image 3 shown. Ti 2 The AlC particles are clearly oriented, from the isotropic uniformity of the casting state to the oriented arrangement of the particle base along the hot extrusion direction.

Embodiment 3

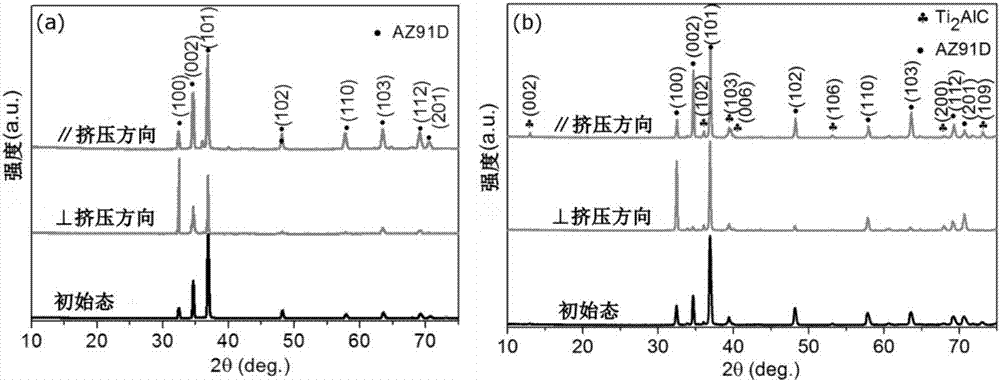

[0027] For 20vol% Ti 2 AlC-Mg based composites were heat treated at 420℃ for 36h to make the Mg alloy uniformly solutionized. Orientation-textured Ti was prepared at 270 °C with an extrusion ratio of 14:1 and a rate of 0.5 / s 2 AlC-Mg based composites. For initial state magnesium alloy and 20vol%Ti 2 AlC-Mg based composites were subjected to the same hot extrusion process, and XRD scans were carried out along the extrusion direction and perpendicular to the extrusion direction, as shown in Fig. Figure 4 (a) and (b) shown. ⊥ extrusion direction, 10vol% Ti compared to pure extruded Mg alloy 2 The intensity of the Mg(002) basal plane diffraction peak in the AlC-Mg-based composite material weakens or even disappears; / / extrusion direction, Ti 2 The AlC(002) basal plane diffraction peak appears and the Mg(002) basal plane diffraction peak is obviously enhanced. It can be seen that under the hot extrusion process, Ti 2 Orientation of AlC particles occurs and strengthens the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com