Carbon nitride/(040) crystal face bismuth vanadate hetero-junction and preparation method and application thereof

A technology of face bismuth vanadate and carbon nitride, which is applied in the field of g-C3N4/crystal face BiVO4 heterojunction and its preparation, can solve the problems of no patent and literature report g-C, no report on method work, etc. Catalytic properties, favorable for efficient separation and migration, developmental integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

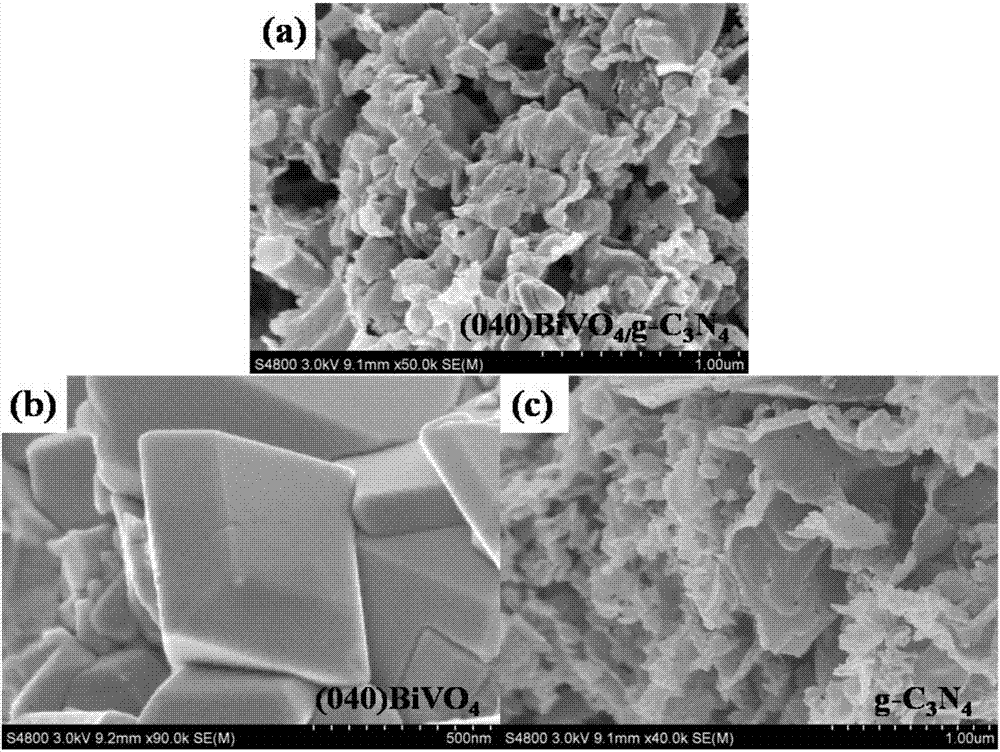

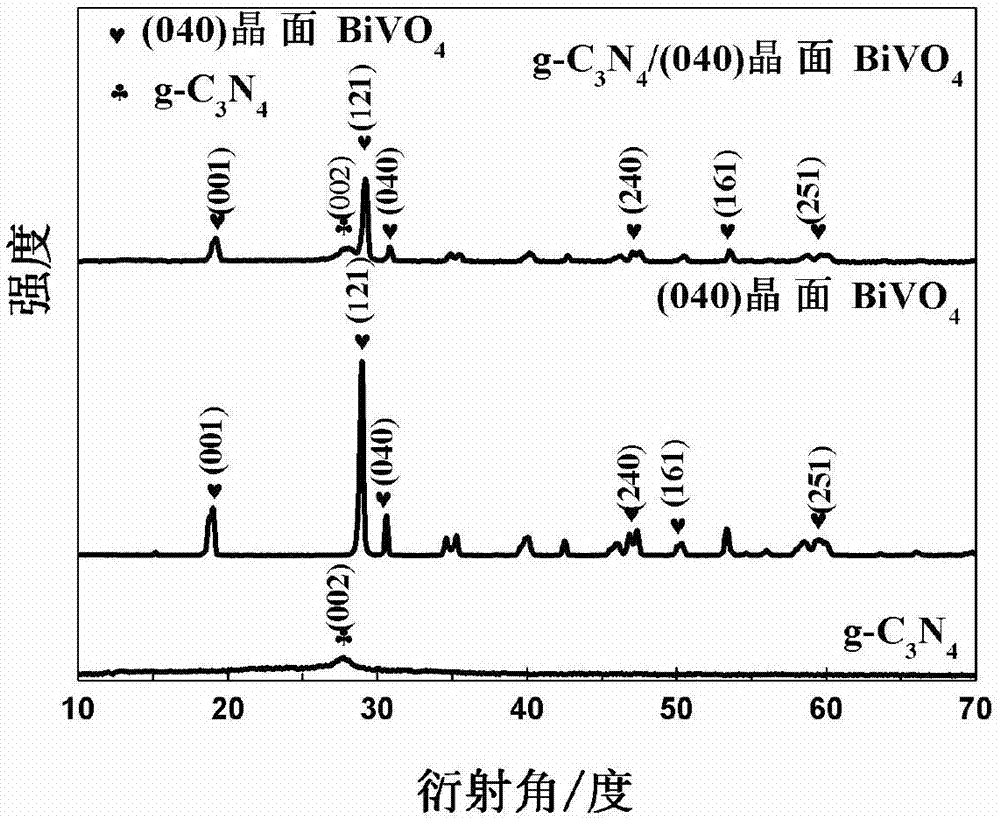

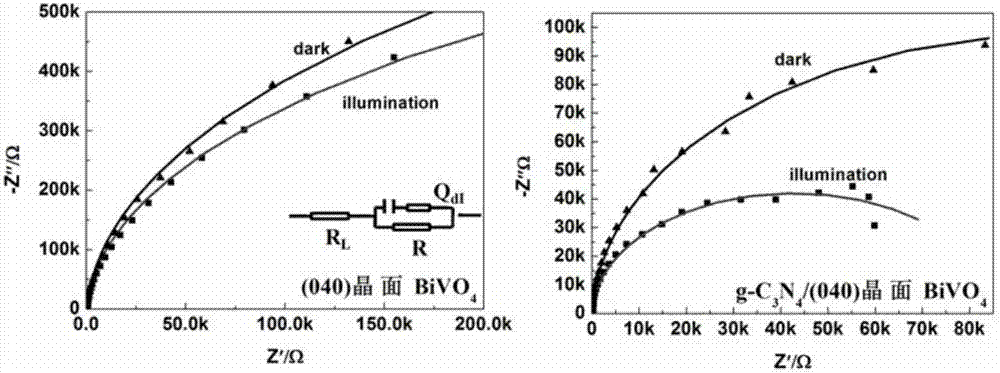

Method used

Image

Examples

Embodiment 1

[0034] Step 1, 6mmoL Bi(NO 3 ) 3 ·5H 2 O dissolves in 1mol / L HNO at a uniform and slow speed under stirring 3 solution, stirred for 30min and slowly added 6mmoL NH 4 VO 3 , stirred for 60min to form precursor solution A, Bi in precursor solution A 3+ The concentration is 0.2mol / L;

[0035] Step 2, Precursor solution A was hydrothermally reacted at 80°C for 15 hours to prepare (040) crystal plane BiVO 4 Precipitate, the precipitate was washed with alcohol and water, and then dried at 70°C for 9 hours to obtain (040) crystal plane BiVO 4 Powder;

[0036] Step 3, CO(NH 2 ) 2 Raise the temperature to 550°C at a rate of 10°C / min, and calcine for 3 hours to obtain g-C 3 N 4 Powder;

[0037] Step 4, under stirring condition, the g-C prepared 3 N 4 Dissolve the powder in deionized water, stir until g-C 3 N 4 The color of the solution becomes light, and until it is uniform, g-C with a concentration of 0.02g / mL is obtained. 3 N 4 solution;

[0038] Step 5, under magne...

Embodiment 2

[0041] Step 1, 6mmoL Bi(NO 3 ) 3 ·5H 2 O dissolves in 1.8mol / L HNO at a uniform and slow speed under stirring conditions 3 solution, stirred for 30min and slowly added 6mmoL NH 4 VO 3 , stirred for 55min to form precursor solution A, Bi in precursor solution A 3+ The concentration is 0.18mol / L;

[0042] Step 2, Precursor solution A was hydrothermally reacted at 78°C for 13.5h to prepare (040) crystal plane BiVO 4 Precipitate, the precipitate was washed with alcohol and water, and then dried at 72°C for 9 hours to obtain (040) crystal plane BiVO 4 Powder;

[0043] Step 3, CO(NH 2 ) 2 Raise the temperature to 530°C at a rate of 10.5°C / min, and calcine for 4 hours to obtain g-C 3 N 4 Powder;

[0044] Step 4, under stirring condition, the g-C prepared 3 N 4 Dissolve the powder in deionized water, stir until g-C 3 N 4 The color of the solution becomes light until it is uniform, and g-C with a concentration of 0.025g / mL is obtained 3 N 4 solution;

[0045] Step 5,...

Embodiment 3

[0048] Step 1, 6mmoL Bi(NO 3 ) 3 ·5H 2 O dissolves in 1.2mol / L HNO at a uniform and slow speed under stirring 3 solution, stirred for 30min and slowly added 6mmoL NH 4 VO 3 , stirred for 75min to form precursor solution A, Bi in precursor solution A 3+ The concentration is 0.22mol / L;

[0049] Step 2, Precursor solution A was hydrothermally reacted at 82°C for 14.5h to prepare (040) crystal plane BiVO 4 Precipitate, the precipitate was washed with alcohol and water, and then dried at 68°C for 9 hours to obtain (040) crystal plane BiVO 4 Powder;

[0050] Step 3, CO(NH 2 ) 2 Rise to 540°C at a heating rate of 9.5°C / min, and calcined for 3.5h to obtain g-C 3 N 4 Powder;

[0051] Step 4, under stirring condition, the g-C prepared 3 N 4 Dissolve the powder in deionized water, stir until g-C 3 N 4 The color of the solution becomes light until it is uniform, and g-C with a concentration of 0.015g / mL is obtained 3 N 4 solution;

[0052] Step 5, under magnetic stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com