Method for preparing nano silver through pyrenochaeta penicillium

A technology of Penicillium aculeatus and Penicillium aculeatus, which is applied in the direction of nanotechnology, metal processing equipment, transportation and packaging, etc. It can solve the problems affecting the application of nanomaterials, harsh conditions of existence, high price, etc., and achieve safe reaction conditions Controllable, unique biological properties, good bio-affinity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

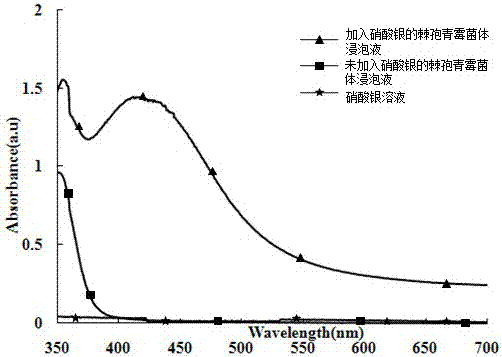

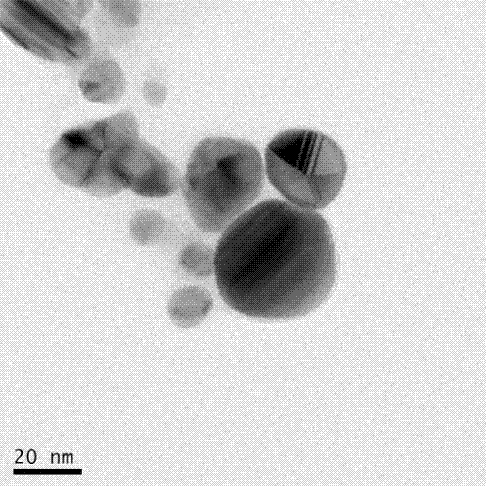

[0038] A kind of method utilizing Penicillium aculeatus to prepare nano-silver

[0039] (1) Obtaining Penicillium aculeatus strains: Inoculate a strain of Penicillium aculeatus on a PDA plate medium, culture it upside down at 30 °C for 72 h to activate the strain, and then add 3 mL of sterile water to the above PDA plate , to obtain a single spore suspension, the concentration of the single spore suspension is 8 × 10 6 spores / mL, take 200 μL of the single spore suspension and add it to 250 mL of sterilized PDB liquid medium, and shake it at 30°C with a rotation speed of 160 rpm for 72 hours. Collect the Penicillium aculeatus thallus by net filtration, and repeatedly wash with sterile deionized water until there is no medium component on the Penicillium aculeatus thallus;

[0040] (2) Preparation of Penicillium aculeatus cell soaking solution: Mix the Penicillium aculeatus cell obtained in step (1) with sterile deionized water at a mass volume ratio of 20 g: 100 mL, then incu...

Embodiment 2

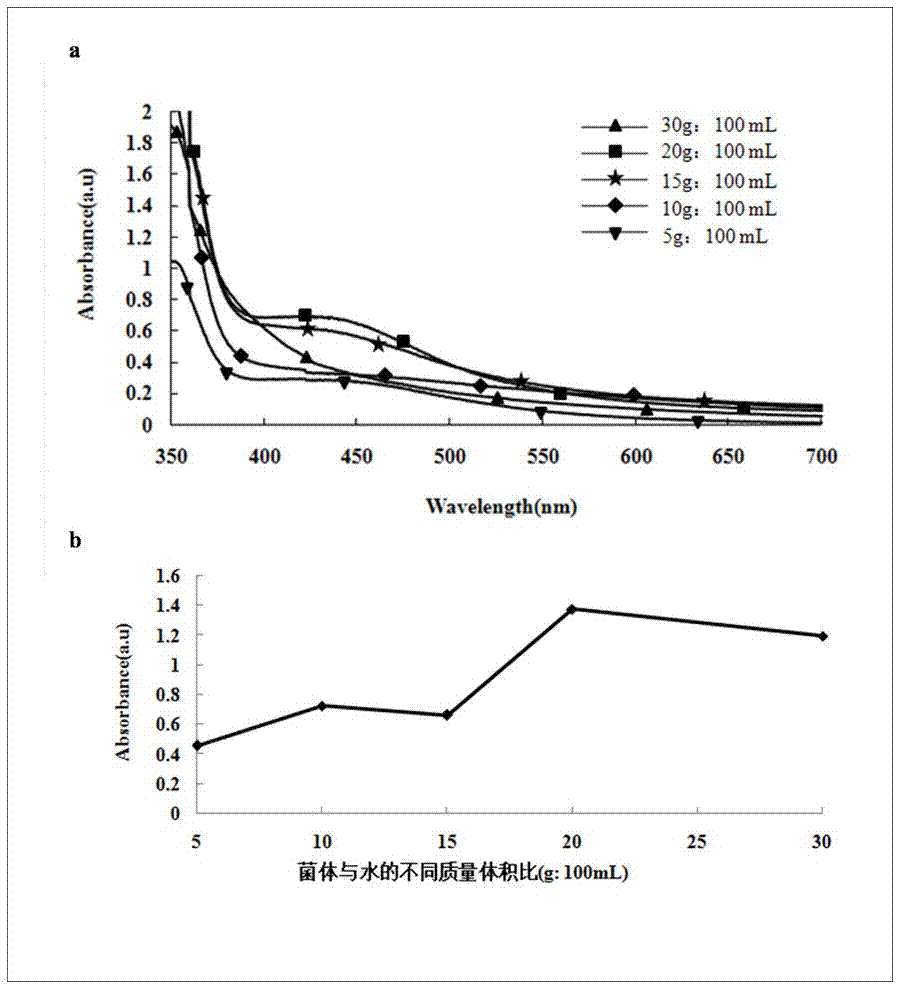

[0043] Effect of the mass-volume ratio of Penicillium aculeatus to water on the preparation of nano-silver during secondary fermentation

[0044] Step (1) is as embodiment 1;

[0045] (2) Preparation of Penicillium aculeatus cell soaking solution: the Penicillium aculeatus cell obtained in step (1) and sterile deionized water were respectively mass-volume ratio 5g: 100 mL, 10g: 100 mL, 15g: 100 mL , 20g: 100 mL, 30g: 100 mL were mixed and cultured for 48 hours at 30°C with a rotation speed of 160 rpm. The five groups of fermentation broth were centrifuged at a rotation speed of 12,000 rpm for 5 minutes, and collected by Whatman No.1 filter paper. clear liquid to prepare 5 groups of Penicillium aculeatus thalline soaking liquids;

[0046] (3) Add silver ions to the five groups of Penicillium aculeatus cell soaking solutions prepared in step (2) respectively, so that the concentration of silver ions is 1.0 mmol / L, adjust the pH value to 8, and react in the dark at 30°C for 72 h...

Embodiment 3

[0048] Effect of fermentation time on the preparation of nano-silver in the secondary fermentation process

[0049] Step (1) is as embodiment 1;

[0050] (2) Preparation of Penicillium aculeatus cell soaking solution: Mix the Penicillium aculeatus cell obtained in step (1) with sterile deionized water at a mass volume ratio of 10 g: 100 mL, and then incubate at 30°C with a rotational speed of 160 rpm Cultivate under shaking for 24 h, 48 h, and 72 h respectively, centrifuge the three groups of fermentation liquids at 12000 rpm for 5 min, filter and collect the supernatant with Whatman No.1 filter paper, and prepare three groups of Penicillium aculeatus cells soaked liquid;

[0051] Step (3) is as in Example 2. During the preparation process, the color change of the reaction solution was observed, and the full wavelength scanning of the reaction solution was carried out with a UV-visible spectrophotometer. The detection range was 300-700 nm, and the scanning interval was 0.5 n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com