Squid ring processing device

A processing device and squid technology are applied in the processing of cephalopods, metal processing, cleaning methods using liquids, etc., which can solve problems such as low labor efficiency and uneven thickness of squid rings, so as to improve processing productivity, ensure hygiene, Safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

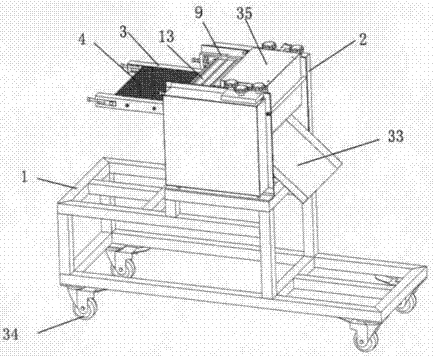

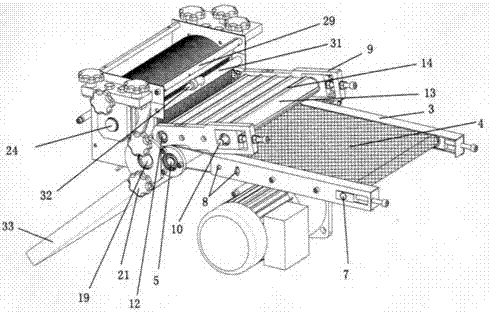

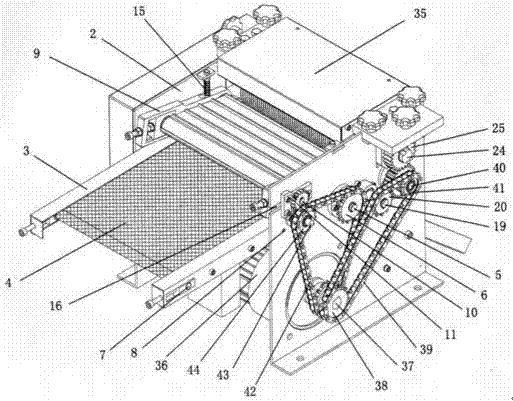

[0028] The squid ring (silk) machine of the present invention includes a rectangular parallelepiped frame, wherein the lower part of the rectangular parallelepiped frame is provided with wheels that can be moved conveniently, and a frame-shaped frame is provided on the cuboid frame, and a raw material conveying device is provided in the frame-shaped frame , A material pressing device is arranged on the upper side of the material conveying device, and a roller is arranged on its side. The roller is arranged in parallel with the combined knife on the upper side and is driven by a motor to rotate relatively; the output end of the aforementioned conveying device is set at The winding end of the combined knife and roller, and the unwinding end of the combined knife and roller are equipped with a discharge hopper.

[0029] The above-mentioned raw material conveying device is composed of a conveyor belt frame, a conveyor belt, a main drive shaft, and a drive shaft. The main drive shaft i...

Embodiment 2

[0035] As in the above example, the number of the front and rear disc blade sets above the material seat are 6 and 7 respectively. If the ring thickness is 10 mm and the disc blade thickness is 1.5 mm, this combination can process frozen squid tubes with a length of 130-150 mm.

Embodiment 3

[0037] As in Example 1, the disc blade has three groups of front, middle and back, and the number of blades in each group is 6 respectively, which can process frozen squid tubes with a length of 180-200 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com