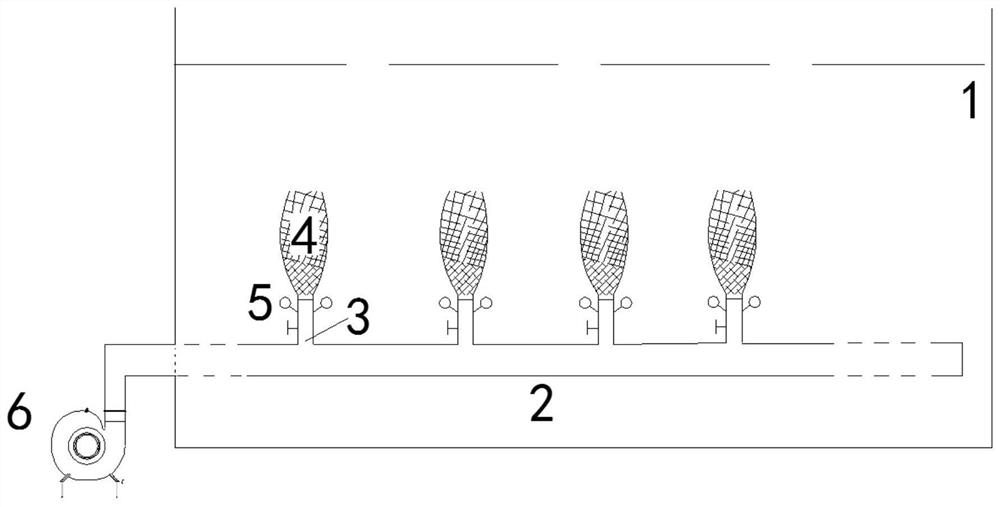

A biofilm reactor

A biofilm reactor and biofilm technology, applied in the field of water treatment, can solve the problems such as the adverse effect of the biofilm reactor film hanging time and sewage degradation efficiency, and inhibit the specific gravity and activity of aerobic microorganisms, so as to shorten the film hanging time, The effect of shortening the film hanging time and improving the specific gravity and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

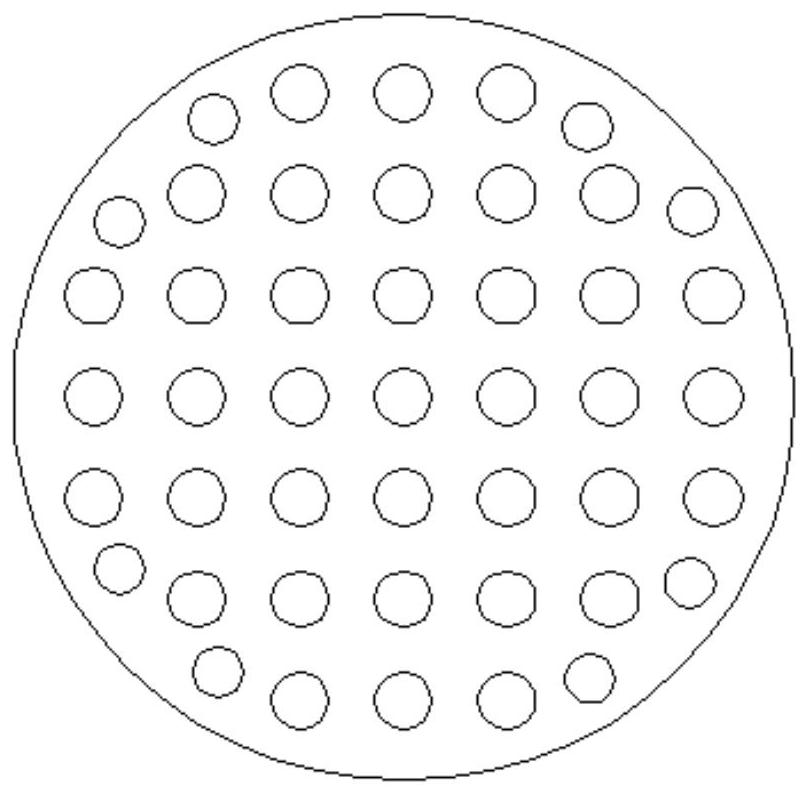

[0042] The preparation method of the above-mentioned biofilm filler is not particularly limited in the present invention, and is preferably prepared according to the following method:

[0043] a) mixing sludge biochar, walnut shell biochar, quicklime, Portland cement, aluminum powder and water to obtain slurry to be poured;

[0044] b) pouring the slurry to be poured into a mold, and the slurry to be poured is gassed and solidified in the mold to obtain a biofilm filler.

[0045] In the preparation method provided by the invention, firstly, sludge biochar, walnut shell biochar, quicklime, Portland cement, aluminum powder and water are mixed to obtain the slurry to be poured. In the present invention, the above-mentioned raw materials are preferably mixed in the following manner:

[0046] a1) mixing sludge biochar, walnut shell biochar, quicklime, Portland cement and water to obtain primary slurry;

[0047] a2) The primary slurry is mixed with aluminum powder to obtain the sl...

Embodiment 1

[0060] Preparation of biofilm filler

[0061] The weight ratio of the components of the biofilm filler is as follows: 0.35g of aluminum powder (200 mesh), 30g of sludge biochar, 25g of pozzolan Portland cement (P.P32.5), 30g of walnut shell biochar, and 17g of lime , 40g of water.

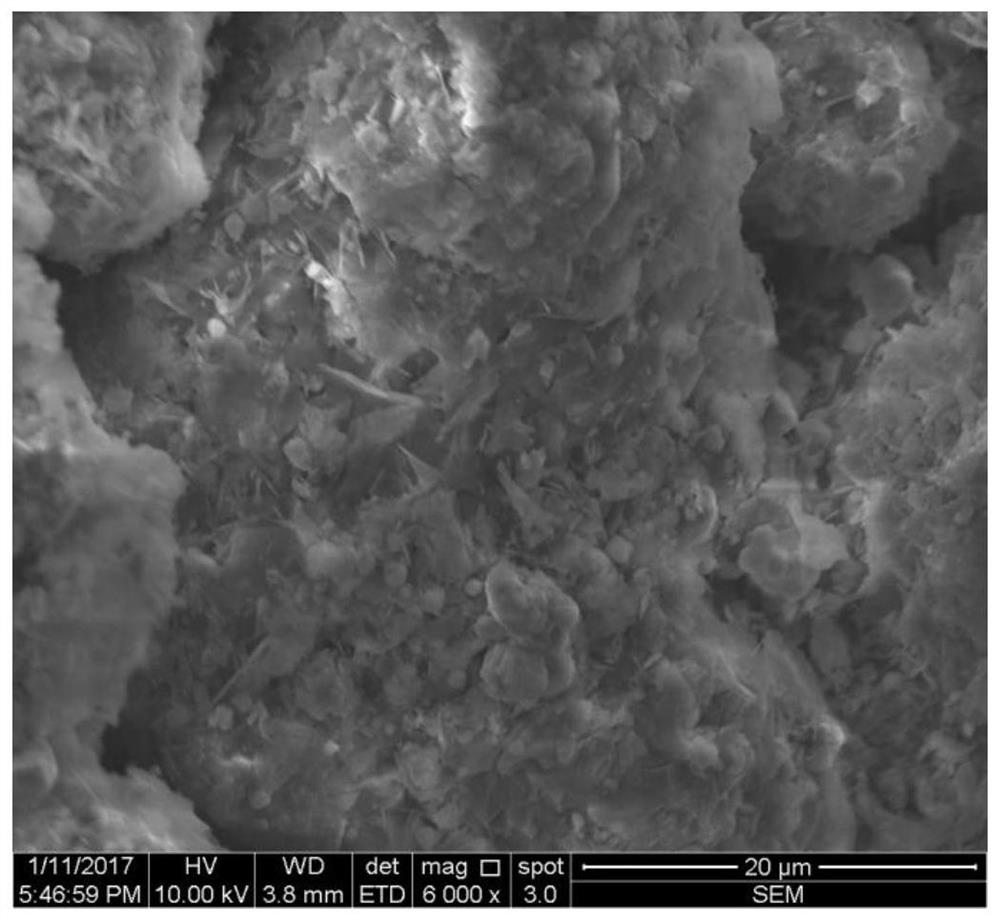

[0062] (1) Preparation of sludge biochar: the residual sludge (water content 55%) of a sewage treatment plant in Guangzhou, after dehydration, was dried in an oven at 105°C to constant weight, crushed into particles of about 0.5mm, and then Move it into a muffle furnace and heat it to 400°C for carbonization at a constant temperature for 60 minutes without air, stop heating, stay in the furnace for 1 hour, and take it out for use. The average particle size, specific surface area and pore volume of the prepared sludge biochar were tested, and the results were: average particle size 0.38mm, specific surface area 51.332m 2 / g, pore volume 0.04621cm 3 / g.

[0063] (2) Preparation of walnut shell bi...

Embodiment 2

[0068] Preparation of biofilm filler

[0069] The weight proportion of each component of biofilm filler is as follows: aluminum powder (300 mesh) 0.40g, sludge biochar 25g, fly ash portland cement (P.F42.5) 25g, walnut shell biochar 32g, Lime 18g, water 42g.

[0070] (1) Preparation of sludge biochar: the residual sludge (water content 60%) of a sewage treatment plant in Guangzhou, after dehydration, was dried in an oven at 110°C to constant weight, crushed into particles of about 0.5mm, and then Move it into a muffle furnace and heat it to 430°C for 1.2 hours of carbonization at a constant temperature without air, stop heating, stay in the furnace for 1 hour, and take it out for use. The average particle size, specific surface area and pore volume of the prepared sludge biochar were tested, and the results were: average particle size 0.36mm, specific surface area 60.401m 2 / g, pore volume 0.06471cm 3 / g.

[0071] (2) Preparation of walnut shell biochar: crush walnut shell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com