Nano-based early strength type compound polycarboxylate water reducer and preparation method thereof

A composite polycarboxylate, early-strength type technology, applied in the field of nano-based early-strength composite polycarboxylate water reducer and its preparation, can solve the negative effect of concrete durability, it is difficult to get rid of steam curing and pressure steaming, equipment Increased investment and other issues, to achieve the effect of reducing the amount of use, no pollution in the preparation process, and reducing the expenditure of the component factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preferred embodiment 1 of the present invention provides a nano-based early-strength composite polycarboxylate water reducer, which is prepared from the following raw materials in mass percentage:

[0037] Early-strength polycarboxylate superplasticizer 18%;

[0038] Nano early strength agent 2%;

[0039] Workability regulator 0.05%;

[0040] Active stimulator 1%;

[0041] Complex stabilizer 0.5%;

[0042] Defoamer 0.04%;

[0043] The balance is water.

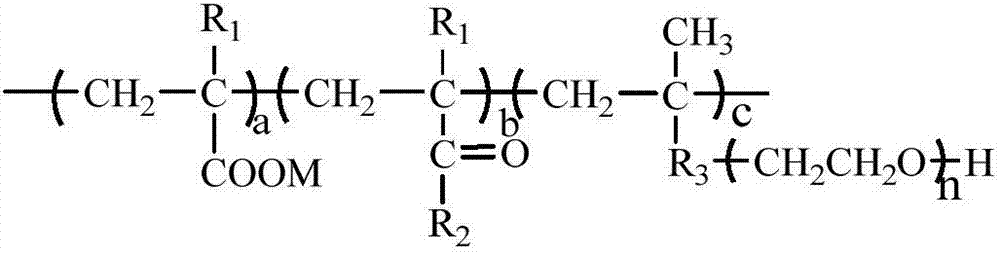

[0044]Wherein, the viscosity-average molecular weight of the early-strength polycarboxylate superplasticizer is 29688, the mass concentration is 40%, and the general structural formula is:

[0045]

[0046] In the formula, a:b:c is 10:1:1;

[0047] where M is

[0048] where R 1 for H, R 2 for NH 2 , R 3 for CH 2 , n=120.

[0049] The preparation method of the nano-accelerated strength agent is as follows: at 25 ° C, 0.2 parts of the early-strength polycarboxylate superplasticizer are stirred and di...

Embodiment 2

[0056] The preferred embodiment 2 of the present invention provides a nano-based early-strength composite polycarboxylate water reducer, which is prepared from the following raw materials in mass percentage:

[0057] Early-strength polycarboxylate superplasticizer 22%;

[0058] Nano early strength agent 4%;

[0059] Workability modifier 0.1%;

[0060] Active stimulator 3%;

[0061] Complex stabilizer 1.5%;

[0062] Defoamer 0.1%;

[0063] The balance is water.

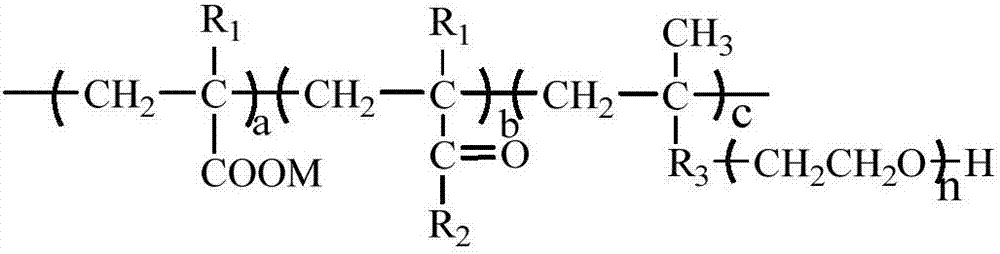

[0064] Wherein, the viscosity-average molecular weight of the early-strength polycarboxylate superplasticizer is 20056, the mass concentration is 40%, and the general structural formula is:

[0065]

[0066]

[0067] where R 1 for H, R 2 for NH-C(CH 3 ) 2 -CH 2 -SO 3 H, R 3 for CH 2 -CH 2 , n=150.

[0068] The preparation method of the nano-accelerated strength agent is as follows: at 25 ° C, 0.5 parts of early-strength polycarboxylate superplasticizer is stirred and dissolved in deionized water, a...

Embodiment 3

[0075] The preferred embodiment 3 of the present invention provides a nano-based early-strength composite polycarboxylate water reducer, which is prepared from the following raw materials in mass percentage:

[0076] Early-strength polycarboxylate superplasticizer 25%;

[0077] Nano accelerator 5%;

[0078] Workability modifier 0.05%;

[0079] Active stimulator 3%;

[0080] Complex stabilizer 0.5%;

[0081] Defoamer 0.04%;

[0082] The balance is water.

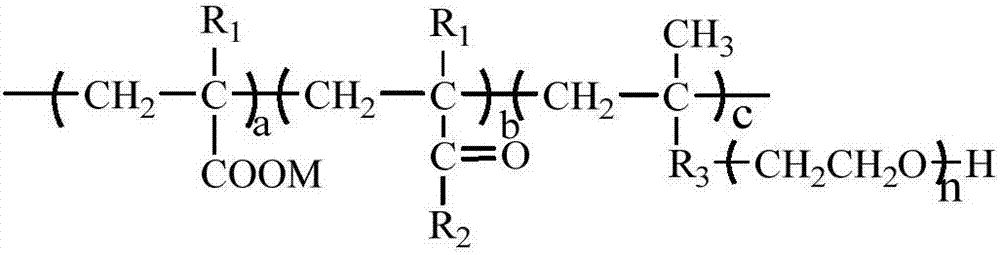

[0083] Wherein, the viscosity-average molecular weight of the early-strength polycarboxylate superplasticizer is 29688, the mass concentration is 40%, and the general structural formula is:

[0084]

[0085] In the formula, a:b:c is 10:2:1;

[0086] where M is

[0087] where R 1 for CH 3 , R 2 for NH 2 , R 3 for CH 2 , n=150.

[0088] The preparation method of the nano-accelerated strength agent is as follows: at 30 ° C, 0.2 parts of the early-strength polycarboxylate superplasticizer are stirred and dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com