Method of utilizing microbial mineralization to treat copper slag to prepare building material

A technology of mineralization treatment and microorganisms, applied in the field of environmental material science, can solve the problems of insufficient utilization of copper slag, shorten the product cycle, reduce environmental pollution problems, and increase the effect of effective capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

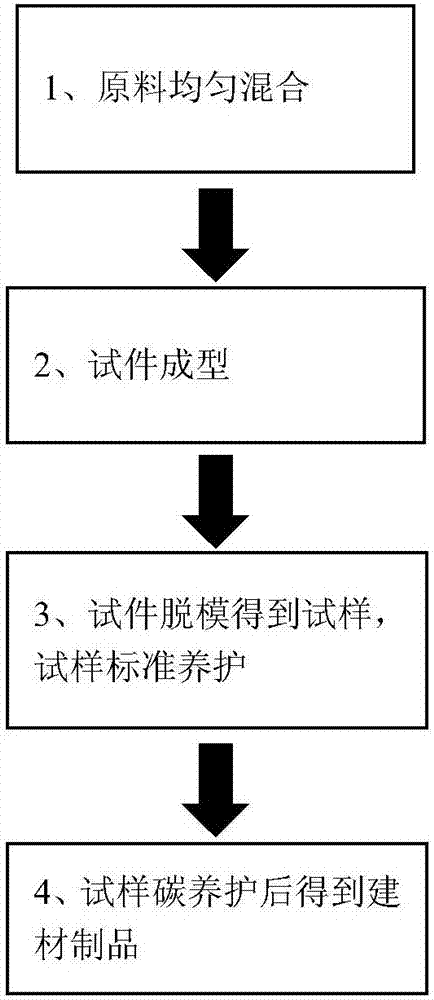

[0031] (1) Copper slag, steel slag and lime are mixed into a composite gelling system according to the ratio of B1 number in Table 1, the fixed mortar ratio is 1:2, the water-cement ratio is 0.5, and the amount of microbial powder is 1.5%;

[0032] (2) Pour 450g of composite gelling material into a stirring pot and stir evenly, add the bacteria powder to 225g of water and stir evenly, then import it into the stirring pot and stir evenly, then add sand and continue stirring evenly, and pour the slurry into the mold Vibrated in the middle to form a test piece.

[0033] (3) Place the test piece in an environment with a relative humidity of 57% and a temperature of 18°C for curing. After 1 day, the sample is demoulded to obtain a sample, and the sample is placed in a standard room with a relative humidity of 95% and a temperature of 18°C for 3 days. Then in normal carbonation environment (CO 2 The volume fraction is 15%, the ambient temperature is 25° C., and the relative hum...

Embodiment 2

[0038] (1) Copper slag, steel slag and lime are mixed into a composite gelling system according to the ratio of C1 number in Table 1, the fixed mortar ratio is 1:3, the water-cement ratio is 0.5, and the amount of microbial powder is 1%;

[0039] (2) After pouring 450g of the composite gelling material into a stirring pot and stirring evenly, adding the bacteria powder into 225g of water and stirring evenly, then introducing it into the stirring pot and stirring evenly. Then add sand and continue to stir evenly, pour the slurry into a mold and vibrate to form a test piece.

[0040] (3) Put the test piece in an environment with a relative humidity of 60% and a temperature of 20°C for curing. After 2 days, the sample is demoulded to obtain a sample. The sample is placed in a standard room with a relative humidity of 96% and a temperature of 20°C for 2 days, and then In a high-pressure carbonization environment (at a humidity of 67%, CO 2Under the condition of pressure of 0.1MPa...

Embodiment 3

[0042] (1) Mix copper slag, steel slag and lime according to the ratio of B2 in Table 1 to form a composite cementitious system, wherein the mass ratio of copper slag: steel slag is 5:1, that is, copper slag 262.5g, steel slag 52.5g, fixed plastic sand The ratio is 1:3, the water-binder ratio is 0.4, and the amount of microbial powder is 2%;

[0043] (2) After pouring 450g of the composite gelling material into a stirring pot and stirring evenly, adding the bacteria powder into 180g of water and stirring evenly, then introducing it into the stirring pot and stirring evenly. Then add sand and continue to stir evenly, pour the slurry into a mold and vibrate to form a test piece.

[0044] (3) Put the test piece in an environment with a relative humidity of 63% and a temperature of 22°C for curing. After 1.5 days, the sample is demoulded to obtain a sample, and the sample is placed in a standard room with a relative humidity of 98% and a temperature of 20°C for 1.5 days. , follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com