Corundum-mullite bricks capable of being used under high temperature and production method thereof

A technology for mullite bricks and high temperature, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problem of shortening the service life of high-temperature furnaces, high-temperature hot blast stoves, corundum mullite brick cracks and peeling, and shortening the life of corundum mullite bricks. Life and other issues, to achieve the effect of preventing cracks and peeling, enhancing hardness and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

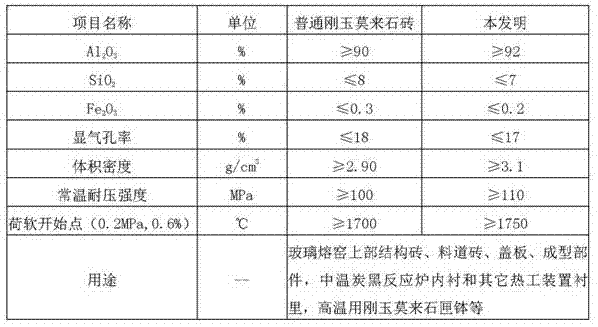

Image

Examples

Embodiment 1

[0021] Example 1: A corundum mullite brick for high temperature, containing the following raw materials in parts by weight, 10 parts of fused white corundum granules, 5 parts of fused white corundum fine powder, fused mullite granules 10 parts of material, 5 parts of fused mullite fine powder material, 5 parts of alumina powder, and 10 parts of kaolin.

[0022] The particle size of the fused white corundum granules and the fused mullite granules are both between 10 and 20 mesh, and the particle sizes of the fused white corundum fine powder and the fused mullite fine powder are both 300 mesh. Between ~350 mesh, the alumina powder is a high-purity alumina modified fine powder with a particle size of less than 625 mesh, and the kaolin is a bonded clay with a particle size of less than 200 mesh.

[0023] The above-mentioned production method of corundum mullite bricks for high temperature includes the process steps of mixing and grinding of raw materials, back-rolling of trapped m...

Embodiment 2

[0029] Embodiment 2: The production method of this embodiment is exactly the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that a kind of high-temperature corundum mullite brick contains the following raw materials in parts by weight, 20 parts of fused white corundum granules, 10 parts of fused white corundum fine powder, 20 parts of fused mullite granules, 10 parts of fused mullite fine powder, 20 parts of alumina powder, and 20 parts of kaolin.

Embodiment 3

[0030] Embodiment 3: The production method of this embodiment is exactly the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that a kind of corundum mullite brick for high temperature contains the following raw materials in parts by weight, 12 parts of fused white corundum granules, 6 parts of fused white corundum fine powder, 18 parts of fused mullite granules, 9 parts of fused mullite fine powder, 10 parts of alumina powder, and 16 parts of kaolin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com