Device and method for preparing silicon rubber for improving quick dissipation of space charges

A space charge and preparation device technology, applied in the field of electrical engineering, can solve problems such as breakdown, local electric field distortion, space charge accumulation, etc., and achieve the effect of stable and controllable reaction process, simple production process and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

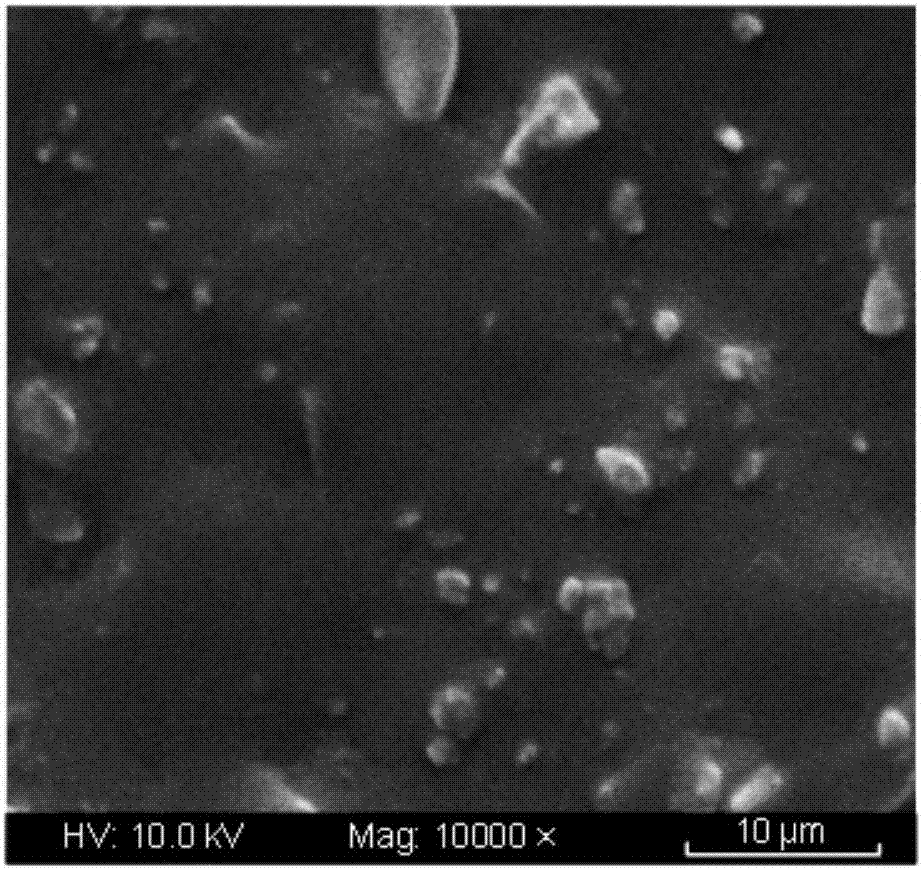

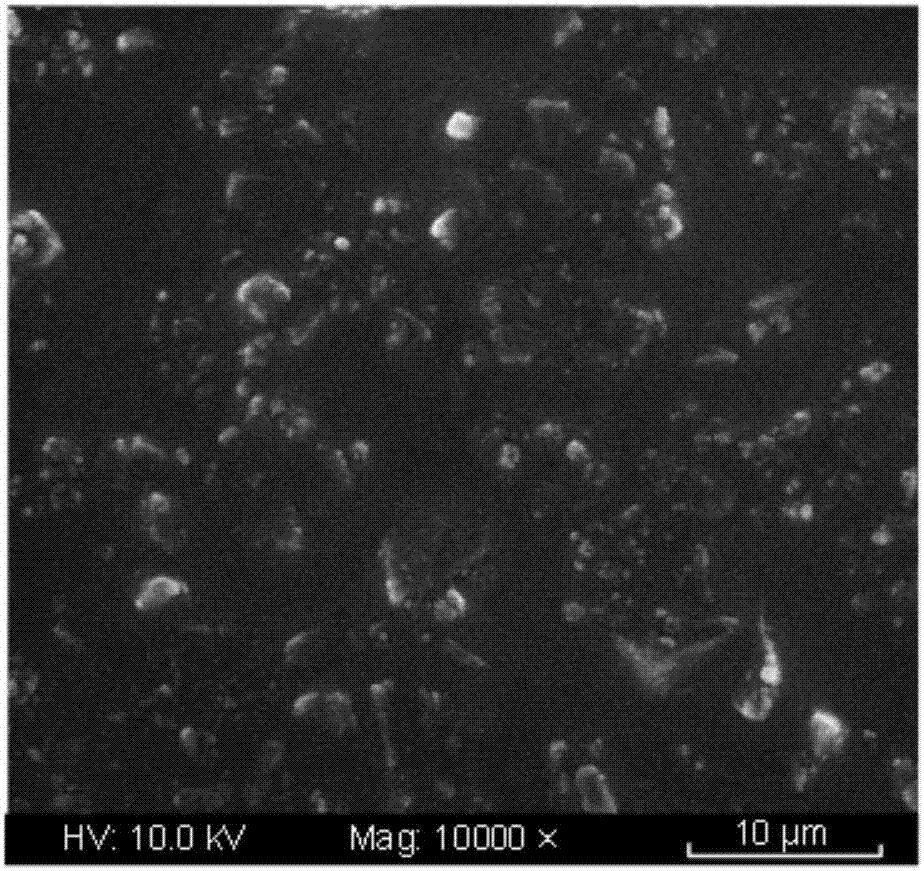

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] The method steps of improving the preparation device of the silicone rubber that the space charge dissipates quickly in the present embodiment are as follows:

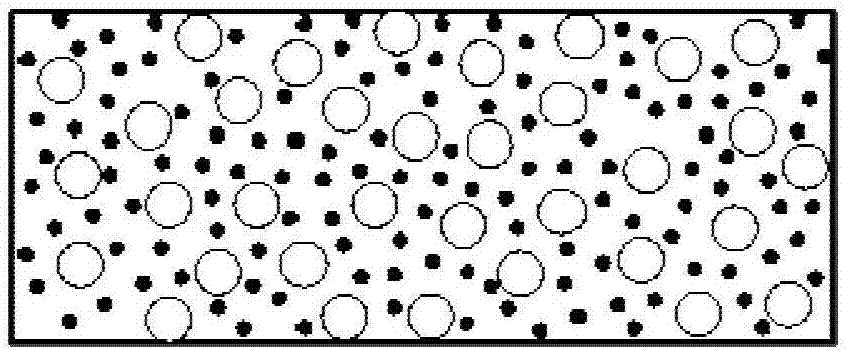

[0030] 1. Use a high-precision electronic balance to weigh 100phr (parts per hundreds of rubber) of silicone rubber matrix, 20phr of nano-silicon dioxide (SiO2), 5phr of hexamethyldisilazane, 1.3phr of polyvinyl silicone oil, 15phr Micron silicon carbide (SiC), 15phr nanometer silicon carbide (SiC) and 1.0phr bis-penta-curing agent, and place the above-mentioned silicone rubber matrix and filler in an oven at 60°C for later use.

[0031] 2. Turn on the heating power supply of the roller of the kneader to heat the roller, and keep the temperature of the roller at 40°C. Adjust the roller speed to 30r / min. Adjust the distance between the roller pitch and the baffle, put 100phr raw silicone rubber into one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com