Waterborne smooth wax handle agent applicable to synthetic leather

A hand feeling agent and synthetic leather technology, which is applied in coating, textile and papermaking, etc., can solve the problems affecting air quality, etc., and achieve the effects of strong rub resistance, excellent wax-slip feel, and good wax-slip feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Add 1g polyvinyl alcohol modified activated clay and 0.5g tea seed powder to 50g water, and heat up to reflux state and mix for 10min, then send it into the ball mill while it is hot, pass through a 200 mesh sieve after ball milling for 5h, and pour into the obtained filtrate Add 5g carbomer resin and 0.5g pregelatinized starch to the mixture, heat up to reflux state again and mix for 30min to obtain water-based carbomer resin emulsion;

[0028] (2) Add 0.5g sepiolite powder, 0.3g carrageenan, 0.3g polyaluminum sulfate and 0.05g nano-zinc borate to 100g water, let stand for 15min after fully dispersed, then heat up to reflux state and mix for 15min, and cool naturally to Room temperature, then add water-based carbomer resin emulsion, 15g soybean protein fiber / poloxamer, 5g chitosan / hydroxypropyl methylcellulose and 2g down fiber / polyvinylpyrrolidone, mix well and send them into a ball mill for ball milling Pass through a 300-mesh sieve after 8 hours, and the resulti...

Embodiment 2

[0033] (1) Add 1 g of polyvinyl alcohol modified activated clay and 1 g of tea seed powder to 50 g of water, heat up to reflux state and mix for 10 minutes, then send it into a ball mill while it is hot, pass through a 200-mesh sieve after ball milling for 5 hours, and pour it into the obtained filtrate Add 5 g of carbomer resin and 0.5 g of pregelatinized starch, heat up to reflux state and mix for 30 minutes to obtain a water-based carbomer resin emulsion;

[0034] (2) Add 0.5g sepiolite powder, 0.5g carrageenan, 0.3g polyaluminum sulfate and 0.05g nano-zinc borate to 100g water, let stand for 15min after fully dispersed, then heat up to reflux state and mix for 15min, and cool naturally to At room temperature, then add water-based carbomer resin emulsion, 20g soybean protein fiber / poloxamer, 3g chitosan / hydroxypropyl methylcellulose and 3g down fiber / polyvinylpyrrolidone, mix well and send them into a ball mill for ball milling Pass through a 300-mesh sieve after 8 hours, a...

Embodiment 3

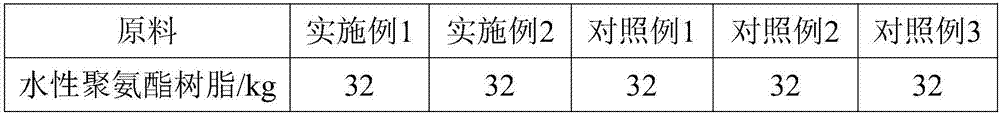

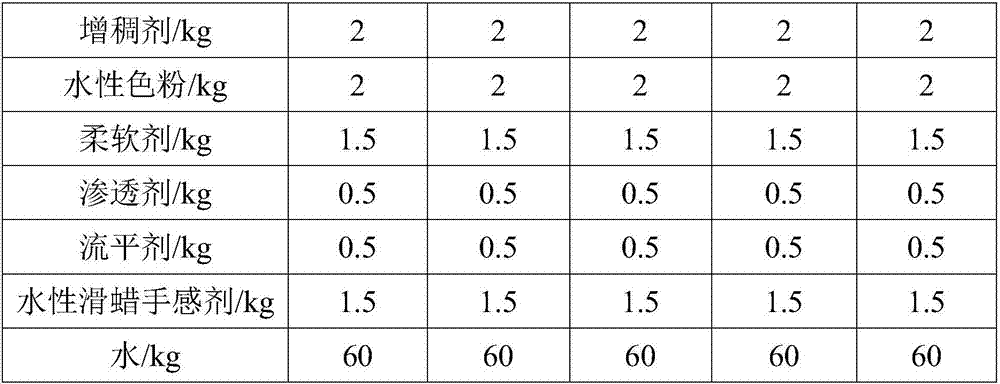

[0051] The water-based wax-sliding hand feeling agent made by equal amounts of Example 1, Example 2, Comparative Example 1, Comparative Example 2 and Comparative Example 3 is added to the water-based polyurethane slurry (the proportioning ratio of slurry raw materials is shown in Table 1, wherein the water-based The added amount of the wax-sliding feel agent is 1.5wt%, in terms of solid content), and the synthetic leather is produced through the same processing technology, and the performance of the synthetic leather is tested, and the results are shown in Table 2.

[0052] Table 1 Synthetic leather preparation slurry ratio table

[0053]

[0054]

[0055] The synthetic leather performance test result of table 2

[0056]

[0057] The test standards for dry rub resistance and wet rub resistance refer to BS EN ISO11640.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com