Ink for preparing luminous layer, preparation method and application

A light-emitting layer and ink technology, applied in applications, organic light-emitting devices, inks, etc., can solve the problems of unsuitable miniaturization operation, complicated light-emitting layer preparation process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

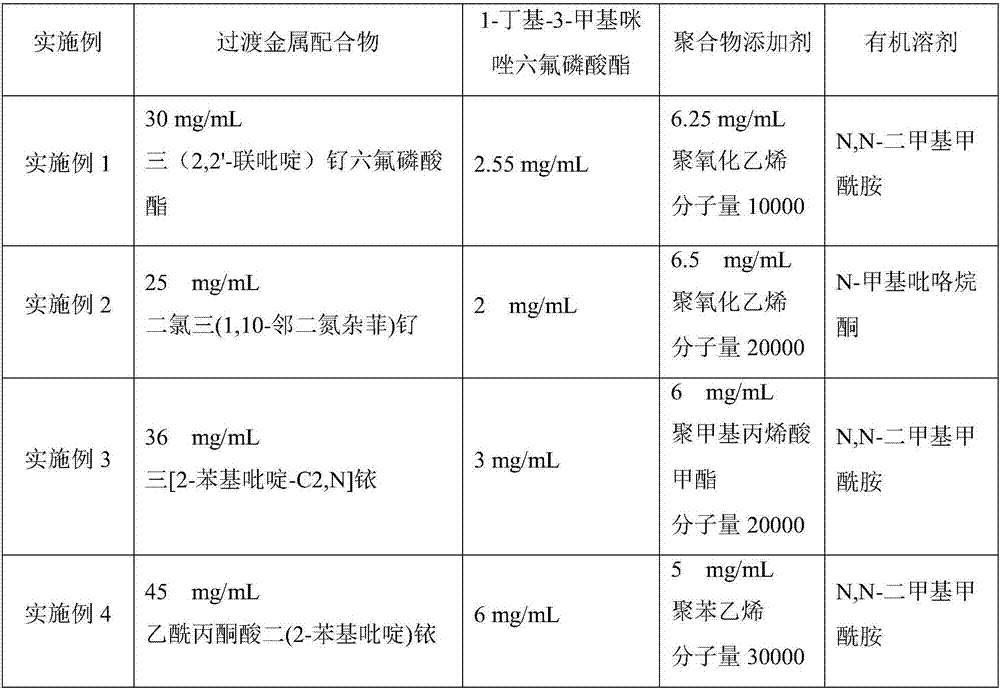

[0030] The second aspect of the present disclosure: provides a method for preparing an ink for making a light-emitting layer of a flexible light-emitting electrochemical cell device, including: a transition metal complex, 1-butyl-3-methylimidazolium hexafluorophosphate and polymerized Additives are mixed with organic solvents to obtain ink; wherein, the concentration of transition metal complexes in the ink is 20-80mg / mL, and the concentration of 1-butyl-3-methylimidazolium hexafluorophosphate is 2-8mg / mL mL, the concentration of the polymer additive is 4-16mg / mL; preferably, the concentration of the transition metal complex in the ink is 30-50mg / mL, 1-butyl-3-methylimidazolium hexafluorophosphate The concentration of the polymer additive is 2-5mg / mL, and the concentration of the polymer additive is 6-10mg / mL.

[0031] According to the second aspect of the present disclosure, 1-butyl-3-methylimidazolium hexafluorophosphate functions as an ion conductor in the light emitting la...

Embodiment 1

[0044] Weigh 40mg tris(2,2'-bipyridyl)ruthenium hexafluorophosphate and 3.4mg 1-butyl-3-methylimidazolium hexafluorophosphate and transfer to 5mL reagent bottle A, measure 1mL N,N -Add dimethylformamide into the reagent bottle and stir to dissolve.

[0045] Weigh 25 mg of polyethylene oxide (weight average molecular weight: 20,000) into a reagent bottle, measure 1 mL of N,N-dimethylformamide into reagent bottle B, and stir to dissolve.

[0046] The solutions in reagent bottle A and reagent bottle B were mixed at a volume ratio of 3:1, stirred, ultrasonicated at 20 kHz for 5 min, and then filtered with a 0.22 μm filter head to obtain ink. The specific composition is shown in Table 1.

[0047] Put the ink into the ink cartridge, and use the inkjet printer to eject ink droplets stably. The specific performance of the ink is shown in Table 2. The luminescent layer made of this ink can meet the use standard.

Embodiment 2-4

[0049] The preparation steps of Example 2-4 are basically the same as that of Example 1. The specific composition is shown in Table 1, and the specific performance of the ink is shown in Table 2. The luminescent layer made by using the ink prepared in Example 2-4 can meet the use standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com