Method for preparing chitosan oligosaccharide from chitosan

A technology of chitin oligosaccharides and chitin, applied in the biological field, can solve the problems of unrecoverable acid and alkali, cumbersome steps, and many steps, and achieve the effects of high environmental protection efficiency, simple reaction conditions, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

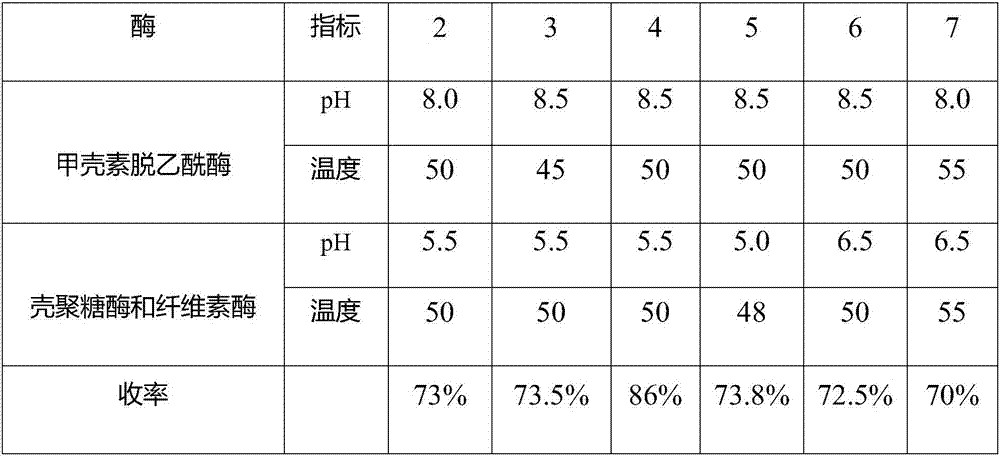

Image

Examples

Embodiment 1

[0020] 1) Weigh 100g of chitin, dissolve it in 1L of water, place in a water bath at 50°C, stir constantly, adjust the pH to 8.5 with 10% sodium hydroxide solution, add 0.1g of chitin deacetylase, and react at constant temperature for 6 hours to obtain chitosan sugar solution;

[0021] 2) Add 31% hydrochloric acid to adjust the pH to 5.5. It can be seen that most of the chitosan precipitates are dissolved in water to form a high-viscosity solution. Add 0.1 g of chitosanase and 0.1 g of cellulase, and stir in a water bath at 50 ° C for 2 hours to obtain Chitosan oligosaccharide solution;

[0022] 3) Add 10% sodium hydroxide to adjust the pH to 8.2, filter to obtain undegraded chitosan residue and degraded chitosan solution, and now the degraded chitosan solution is a light yellow clear liquid, and the above-mentioned undegraded The chitosan residue is filtered, joins in the next batch of preparation method step 2), circulates back and forth, to improve the productive rate of c...

Embodiment 2

[0026] 1) Weigh 100g of chitin, dissolve it in 1L of water, place in a water bath at 50°C, stir constantly, adjust the pH to 8.5 with 10% sodium hydroxide solution, add 0.1g of chitin deacetylase, and react at constant temperature for 6 hours to obtain chitosan sugar solution;

[0027] 2) Add 31% hydrochloric acid to adjust the pH to 5.5. It can be seen that most of the chitosan precipitates are dissolved in water to form a high-viscosity solution. Add 0.1 g of chitosanase and 0.1 g of cellulase, and stir in a water bath at 50 ° C for 2 hours to obtain Chitosan oligosaccharide solution;

[0028] 3) Add 10% sodium hydroxide to adjust the pH to 8, filter to obtain undegraded chitosan residue and degraded chitosan solution, the degraded chitosan solution is light yellow clear liquid, the above-mentioned undegraded The chitosan residue is filtered, joins in the next batch of preparation method step 2), circulates back and forth, to improve the productive rate of chitosan oligosac...

Embodiment 3

[0032] 1) Weigh 100g of chitin, dissolve it in 1L of water, place in a water bath at 50°C, stir constantly, adjust the pH to 8.5 with 10% sodium hydroxide solution, add 0.1g of chitin deacetylase, and react at constant temperature for 6 hours to obtain chitosan sugar solution;

[0033] 2) Add 31% hydrochloric acid to adjust the pH to 5.5. It can be seen that most of the chitosan precipitates are dissolved in water to form a high-viscosity solution. Add 0.1 g of chitosanase and 0.1 g of cellulase, and stir in a water bath at 50 ° C for 2 hours to obtain Chitosan oligosaccharide solution;

[0034] 3) Add 10% sodium hydroxide to adjust the pH to 8.5, filter to obtain undegraded chitosan residue and degraded chitosan solution, the degraded chitosan solution is light yellow clear liquid, the above-mentioned undegraded The chitosan residue is filtered, joins in the next batch of preparation method step 2), circulates back and forth, to improve the productive rate of chitosan oligos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com