Method for synthesizing large-sized zinc oxide crystals by using microwaves

A microwave synthesis, large-scale technology, applied in chemical instruments and methods, crystal growth, self-solid, etc., can solve the problem of small zinc oxide single crystal size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

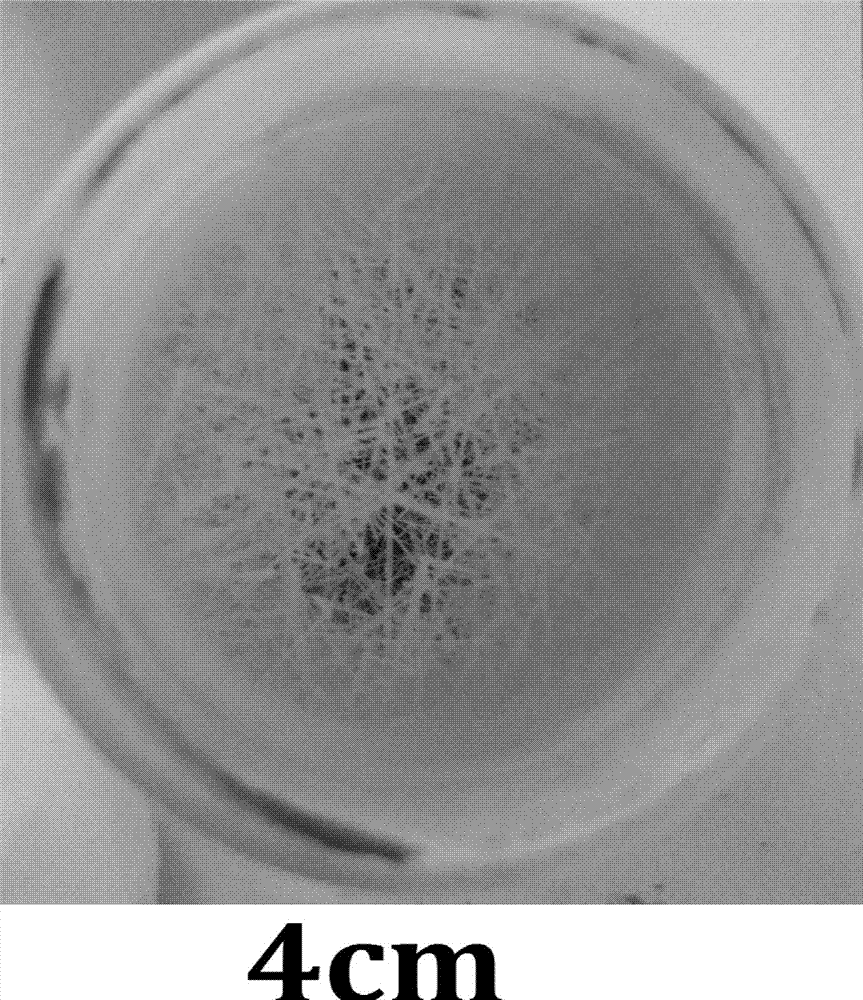

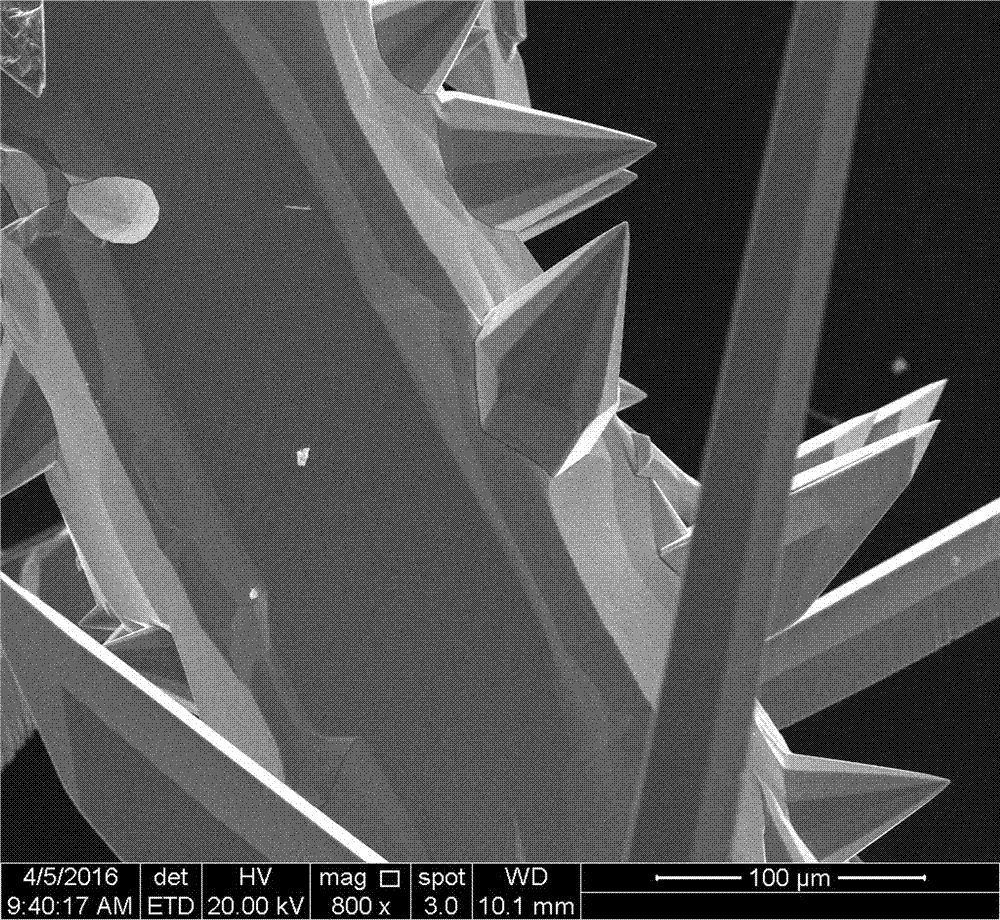

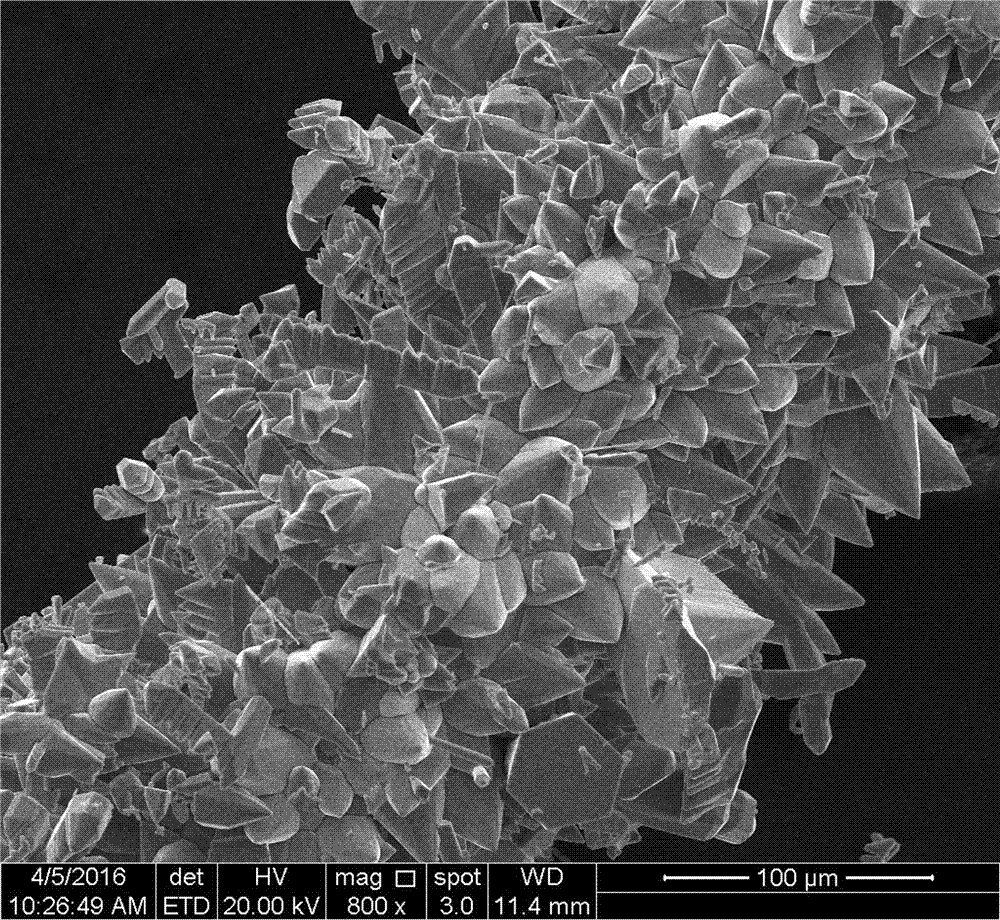

[0035] Graphite powder with an average particle size of 2 μm, high-purity zinc oxide with an average particle size of 1 μm and copper particles with an average particle size of 1 mm are used as raw materials, and the powders are weighed according to the mass of C: ZnO: copper particles of 2.25 grams, 4.5 grams and 0.475 grams. Then mix in a mortar and mortar for 30 minutes so that it is well combined. The prepared raw materials were put into a quartz crucible with an inner diameter of 45 mm, placed in a microwave muffle furnace for reaction synthesis, the heating rate was 30 °C / min, the synthesis temperature was 1100 °C, and the temperature was kept for 1 h. After cooling with the furnace, the white needle-shaped product obtained on the inner wall of the crucible is the needle-shaped zinc oxide crystal with a length of 1 to 2 cm. The white needle-shaped product was detected, and the results were as follows: Figure 1-3 shown.

Embodiment 2

[0037] Activated carbon powder with an average particle size of 3 μm, high-purity zinc oxide with an average particle size of 1 μm and copper particles with an average particle size of 0.1 mm are selected as raw materials, and the mass of C: ZnO: copper particles is 2.25 grams, 2.25 grams and 0.25 grams. Take the powder and mix it in a mortar for 40 minutes to make it evenly mixed. The prepared raw materials were put into a quartz crucible with an inner diameter of 45mm, placed in a microwave muffle furnace for reaction synthesis, the heating rate was 10°C / min, the synthesis temperature was 1050°C, and the temperature was kept for 1.5h. After cooling with the furnace, the white needles obtained on the inner wall of the crucible are needle-shaped zinc oxide crystals, such as Figure 4 shown.

Embodiment 3

[0039] Choose graphite powder with an average particle size of 3 μm, high-purity zinc oxide with an average particle size of 1 μm, and copper particles with an average particle size of 0.5 mm as raw materials, and weigh the powder according to the mass of C: ZnO: copper particles: 2.25 grams, 3.25 grams, and 0.275 grams , then mix in the mortar for 30 minutes to combine well. The prepared raw materials were put into a quartz crucible with an inner diameter of 45mm, placed in a microwave muffle furnace for reaction synthesis, the heating rate was 20°C / min, the synthesis temperature was 1100°C, and the temperature was kept for 0.5h. After cooling down in the furnace, the white needle-shaped product obtained on the inner wall of the crucible is the needle-shaped zinc oxide crystal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com