Environment-friendly polysilsesquioxane nano-hybrid super-hydrophobic coating material and preparation method thereof

A technology of polysilsesquioxane and superhydrophobic coating, which is applied in textiles and papermaking, fiber treatment, plant fibers, etc., can solve the problem of less PSQ nanosphere hybrid materials, and achieve large-area film production and improve Effect of washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

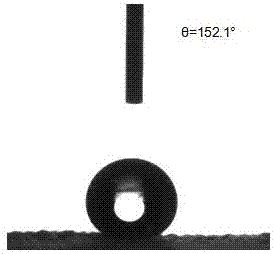

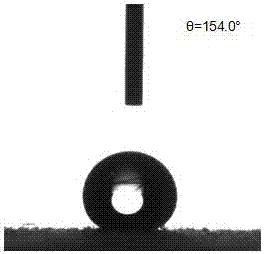

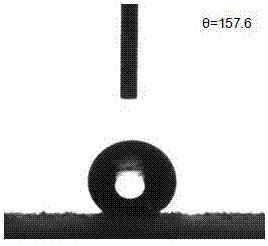

Image

Examples

preparation example Construction

[0030] The invention relates to a preparation method of polymethyl / long-chain alkyl silsesquioxane emulsion, which is applied to the preparation of environment-friendly polysilsesquioxane nano-hybrid superhydrophobic coating material, through layer by layer self- Assembly technology applies it in the finishing of cotton fabrics.

[0031] Specifically include the following steps:

[0032] Step 1: Add sodium dodecylsulfonate, Tween-80, alkali catalyst and distilled water into the reaction kettle, and stir at room temperature (15-25°C) for 30-40min; sodium dodecylsulfonate and Tween-80 are Compound emulsifier, the mass ratio is 1:1, the mass ratio of compound emulsifier to distilled water is 1: (100-150), and the amount of alkali catalyst per 1L of distilled water is 0.025-0.1mol;

[0033] Then add methylsilane dropwise to the system, control the drop rate to 20 drops / min, react at room temperature for 30 minutes after the drop, then start to add long-chain alkyl silane dropwise...

Embodiment 1

[0046] (1) Accurately weigh 0.20g of sodium dodecylsulfonate, 0.20g of Tween80, 0.1g of NaOH and 50.00g of deionized water, add them into the reaction kettle, and stir for 30min at room temperature at 15°C. Add 4.90 g of methyltriethoxysilane dropwise to the system through a constant pressure dropping funnel, control the dropping rate (20 drops / min), react at room temperature for 30 minutes after the dropping, and then start dropping 1.00 g of ten Dialkyltriethoxysilane was kept warm and stirred for 8 hours to obtain a light blue translucent liquid, which was a monodisperse PLMSQ nano-hybrid emulsion (average particle size 50.58 nm, PDI 0.125).

[0047] (2) Immerse the natural cotton fabric in the γ-glycidyl etheroxypropyltrimethoxysilane bath solution with a mass percentage concentration of 1% (adjust pH=5-6 with hydrochloric acid) for 0.5 minutes, take out the cloth sample, and Bake at 100°C for 10 minutes.

[0048] (3) Immerse the cloth sample treated in (2) into the PLMSQ...

Embodiment 2

[0051] (1) Accurately weigh 0.22g of sodium dodecylsulfonate, 0.22g of Tween80, 0.15g of KOH and 50.00g of deionized water, and add them in sequence to a three-necked bottle equipped with a thermometer, reflux device and electric stirrer, at room temperature of 20°C , stirred for 35min. Add 5.71g of methylethoxysilane dropwise to the system through a constant pressure dropping funnel, control the dropping rate (20 drops / min), react at room temperature for 30min after the dropping, and then start dropping 1.39g of hexadecane at the same dropping rate Alkyltrimethoxysilane, continue to keep warm and stir for 10h to obtain a light blue translucent liquid, which is a monodisperse PLMSQ emulsion (average particle size is 65.97, PDI is 0.173).

[0052] (2) Immerse the natural cotton fabric in the bath solution of γ-glycidyl etheroxypropyl triethoxysilane with a mass percentage concentration of 3% (adjust pH=5-6 with hydrochloric acid) for 1 min, take out the cloth sample, and Bake ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com